Abstract

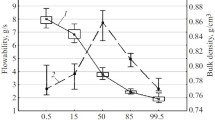

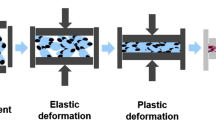

Seven commercially available pharmaceutical excipients used for direct tableting were studied. Flowability, true and tap density, loss on drying, particle size, specific surface area and scanning electron micrographs were used to characterize these powders with low compaction pressures (lower than 10 MPa). The relaxation mode was analysed to describe the behaviour of each product under strain. Three new models are proposed to aid understanding the physical phenomena involved in the compaction phase, and the Peleg model was applied to the relaxation phase. The models were related with the physical properties measured, and illustrate the sliding friction, the viscoelastic behaviour and the aptitude of particles to fragment during compaction, as well as the elastic behaviour during the stress relaxation of powders.

Similar content being viewed by others

References

M. Celik, Drug Dev. Ind. Pharm. 18 (1992) 767.

Idem., ibid. 22 (1996) 1.

J. C. Guyot, A. Delacourte, P. Bleuse and P. Leterme, Sci. Tech. Pharm. 263 (1982) 427.

R. W. Heckel, Trans. Metall. Soc. AIME. 221 (1961) 671.

M. Peleg and M. D. Normand,Rheol. Acta. 22 (1983) 108.

Y. Noël and C. Achilleos, Cahier de Rhéologie. 15(4) (1997) 568.

P. Sabre, Y. Bourtel, F. Bouvier and M. Serpelloni, ibid. 15(4) (1997) 574.

M. Peleg, J. Food Sci. 44 (1979) 277.

P. Carmona, P. Michaud, J. F. Cordoliani, D. Chulia and F. Rodriguez, Cahier de Rhéologie. 13(4) (1996) 807.

C. Lanos and A. Vuez, ibid. 15(4) (1997) 21.

H. H. Hausner, Int. J. Powder Metall. 3 (1967) 7.

R. L. Carr, Chem. Eng. 18 (1965) 163.

G. Alderborn and C. Ahlneck,Int. J. Pharm. 73 (1991) 249.

J. Schwartz, N. H. Nguyen and R. L. Schnaare, Drug Dev. Ind. Pharm. 20(20) (1994) 3105.

C. NystrÖm, G. Alderborn, M. Duberg and P. G. Karehill, ibid. 19 (1993) 2143.

Y. Gonthier, Doctoral thesis, Pharmaceutical Sciences, Grenoble I 1984.

A. MUÑOZ ruiz, T. PAYÀN Villard, N. MUÑOZ MuÑoz, M. C. MONEDERO Perales and M. R. JimÉnez-Castellanos, Int. J. Pharm. 110 (1994) 37.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Galley, O., Lovera, V., Viana-Trecant, M. et al. New models to explain the compaction and relaxation behaviour of some pharmaceutical excipients submitted to low strain. Journal of Materials Science 35, 2037–2046 (2000). https://doi.org/10.1023/A:1004747309396

Issue Date:

DOI: https://doi.org/10.1023/A:1004747309396