Abstract

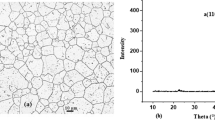

The electrochemical behaviour of direct strip casting (DSC) 304 stainless steel in 0.1 M H2SO4 and 0.01M HCl solutions was investigated. The DSC 304 stainless steel strips were produced by using either copper-alloy roller or 304 stainless steel roller. The difference in thermal conductivity of different roller materials resulted in a change in the surface microstructure of the DSC strips. Potentiodynamic polarization curves of the DSC 304 stainless steels produced were measured in 0.1M H2SO4 and 0.01M HCl solutions. The results showed that both alloys could passivate in the above solutions. In the HCl solution, the passive potential range of DSC 304 stainless steel with a higher ferrite content prepared by the copper roller was wider than that with a lower ferrite content. Furthermore, the addition of silicon could cause an expansion while the addition of titanium could lead to a shrinkage in the passive range in 0.01M HCl solution. Potential decay tests in 0.1M H2SO4 solutions showed that the reactivation time decreased as the ferrite content was increased. © 1998 Chapman & Hall

Similar content being viewed by others

References

K. Shibuya and M. Ozawa, ISIJ Int. 31 (1991) p. 661.

G. L. Houze, N. E. Cieslinski, D. B. Love, G. M. Carinci and B. Lindorfer, in “VAI-Symposium”, Technical Reports, Taipei, June 1993, p. 38/1.

R. S. Carbonara, in “Proceedings of an International Symposium on Casting of Near Net Shape Products”, edited by Y. Sahai, J. E. Battles, R. S. Carbonara and C. E. Mobley (The Metallurgical Society/AIME, Warrendale, PA, 1988) p. 169.

D. C. Dean, Iron Steelmaker 15 (1988) p. 12.

T. Yamauchi, T. Nakanori, M. Hasegawa, T. Yabuki and N. Ohnishi, Trans. Iron Steel Inst. Jpn 28 (1988) p. 24.

TH. Schubert, W. Loser, S. Schinnerling and I. Bacher, Mater. Sci. Technol. 11 (1995) p. 181.

D. Raabe, Metall. Mater. Trans. 26A (1995) p. 991.

T. Mizoguchi and K. Miyazawa, ISIJ Int. 35 (1995) 771.

H. Yasunaka, K. Taniguchi, M. Kokita and T. Inoue, ibid. 35 (1995) 784.

R. K. Pitler, in “Advanced High-Temperature Alloys: Processing and Properties”, edited by S. M. Allen, R. Pelloux and R. Widmer (American Society for Metals, Metals Park, OH, 1986) p. 1.

M. Seo, G. Hultquist, C. Leygraf and N. Sato, Corros. Sci. 26 (1986) 949.

T. N. Rhodin, Corrosion 12 (1956) 123t.

B. E. Wilde, ibid. 42 (1986) 147.

W. Tsai, Y. Wen, J. Lee, H. Liou and W. Wang, Surf. Coat. Technol. 34 (1986) p. 209.

S. C. Srivastava and M. B. Ives, Corrosion 45 (1989) p. 488.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chou, SL., Lin, CY., Lee, JT. et al. The electrochemical behaviour of direct strip casting stainless steel in acid solutions. Journal of Materials Science 33, 2413–2419 (1998). https://doi.org/10.1023/A:1004364126675

Issue Date:

DOI: https://doi.org/10.1023/A:1004364126675