Conclusions

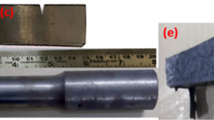

Modification of gray test iron with as much as 0.08% Mg leads to globularization of graphite and greatly changes the average rate of fracture. The fracture of the pearlitic matrix is brittle in character. The fracture of the pearlitic matrix is brittle in character. Thus, the discrete pattern of crack propagation observed is due mainly to the presence of graphite inclusions, which are areas of scattering of the elastic energy of the crack — relaxation areas. Comparison of the electron fractographs of cast and heat-treated samples (alloy with 0.08% Mg) revealed new elements of brittle fracture in the latter. Crack propagation in the ferritic cast iron is a ccompanied by intensive twinning (Fig. 3g, positive replica). It should be noted that ferritizing annealing has a negligible effect on the average rate of crack propagation (∼350 m/sec).

The presence of ferrite in castings of alloys modified with 0.15 and 0.23% Mg has a negligible effect on the fracture, since the ferrite contains silicon and is therefore not a ductile phase. Comparison of the type of fracture leads to the conclusion that fracture can be regarded as brittle for all the cast irons tested. The change in the fine structure of the fracture surface with increasing magnesium concentrations first manifest in increasing signs of brittle fracture (up to 0.08% Mg) and then in weakening of these signs, is due to the change in the rate of crack propagation, which in turn depends on the shape and distribution of graphite, depending on the structural condition of the cast iron.

Similar content being viewed by others

Literature cited

L. G. Orlov and L. M. Utevskii, "A study of the micromechanism of the fracture process in steel and iron by the electron fractographic method," in: Problems of Metal Science and Physics of Metals [in Russian], No. 7, Metallurgizdat, Moscow (1962), p. 157.

I. S. Guz' et al., "Effect of magnesium content and character of crack propagation in cast iron castings during dynamic bending," Liteinoe Proizvod., No. 9, 13 (1976).

F. N. Tavadze et al., "Effect of heat treatment on the properties of steel 03Kh13AG19 at cryogenic temperatures," Metalloved. Term. Obrab. Met., No. 2, 56 (1975).

V. S. Ivanova et al., "Fractograph study of fracture toughness of aluminum and titanium alloys," Probl. Prochn., No. 11, 25 (1972).

Additional information

Institute of Problems of Machine Construction, Academy of Sciences of the Ukrainian SSR. V. I. Lenin Kharkov Polytechnic Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 26–28, August, 1979.

Rights and permissions

About this article

Cite this article

Guz, I.S., Matsevityi, V.M., Molodtsov, S.L. et al. Characteristics of the fracture surface of gray magnesium cast irons after dynamic fracture. Met Sci Heat Treat 21, 599–602 (1979). https://doi.org/10.1007/BF00703601

Issue Date:

DOI: https://doi.org/10.1007/BF00703601