Abstract

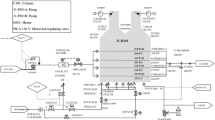

To improve the safety of plant start-up operation, a safety evaluation system has been developed. As a key component in an operational design support system, the evaluation system examines any potential hazards during start-up operation simulation. The evaluation system is integrated into an operational design methodology which designs operable processes by proposing alternatives, examining process safety and operability, and modifying operating procedures or plant structures. Issues for both methodology and implementation of a G2-based expert system are discussed. Finally, the system is applied to an industrial hydrodesulphurization process.

Similar content being viewed by others

References

Batres, R., Naka, Y., Adriani, A., Arai, K., Lu, M. L., Pradubsripetch, D., Lee, S. and Yamada, I. (1995) Operational design for startup and shutdown of chemical plants based on a topological approach, in Proceedings of First International Plant and Design Conference, AIChE Spring Meeting, pp.211–219.

Catino, C. A. and Ungar, L. H. (1995) Model-based approach to automated hazard identification of chemical plants. Journal of the American Institute of Chemical Engineers, 41, 97–109.

Centre for Chemical Process Safety (1992) Guidelines for Hazard Evaluation Procedures, 2nd edn, American Institute of Chemical Engineers, New York.

Crowl, D. A. and Louvar, J. F. (1990) Chemical Process Safety: Fundamentals with Applications, Prentice Hall, Englewood Cliffs NJ.

Lee, S., Batres, R., Lu, M. L. and Naka, Y. (1996) Study on safety evaluation for startup, in Proceedings of the 5th World Congress of Chemical Engineering, San Diego CA.

Naka, Y. and McGreavy, C. (1994) Modular approach for start-up operational procedures of chemical plants, in Proceedings of PSE 94, Kyangju, Korea, pp. 1007–1013.

Nimmo, I. (1994) Extend HAZOP to computer control systems. Chemical Engineering Progress, 90, 32–44.

Vaidhyanathan, R. and Venkatasubramanian, V. (1995) Digraph-based models for automated HAZOP analysis. Reliability Engineering and System Safety, 50, 33–49.

Vaidhyanathan, R. and Venkatasubramanian, V. (1996) Experience with an expert system for automated HAZOP analysis. Computers and Chemical Engineering, 20, S1589–1594.

Venkatasubramanian, V. and Vaidhyanathan, R. (1994a) HAZOP Expert: a knowledge-based system for HAZOP analysis in Proceedings of PSE 94, Kyangju, Korea, pp.1117–1122.

Venkatasubramanian, V. and Vaidhyanathan, R. (1994b) A knowledge-based framework for automating HAZOP analysis. Journal of the American Institute of Chemical Engineers, 40, 496–505.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

LEE , S., PARK , S. A knowledge-based approach to safety evaluation for plant start-up. Journal of Intelligent Manufacturing 8, 517–524 (1997). https://doi.org/10.1023/A:1018530904691

Issue Date:

DOI: https://doi.org/10.1023/A:1018530904691