Abstract.

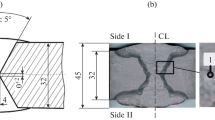

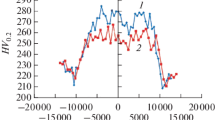

Residual stresses due to TIG welding have been measured using neutron diffraction and the results compared with a finite element model calculation. Measurements were made on a single-pass, autogenous, bead-on-plate TIG weld made along the centre line of an aluminium alloy rectangular plate of dimensions 172×150×3 mm3. The weld is 150 mm long with the start and end pools centred approximately 12 mm from the plate edges. There is an 8 mm wide molten band on the crown surface of the weld. Measurements were made at a neutron wavelength of 1.51 Å using the aluminium (311) reflection and a gauge volume ≈2×2×2 mm3. Scans were made along three transverse lines, across the centre of the weld, 40 mm from the start and 40 mm from the end at mid-thickness. Stresses were derived using data collected in the three orthogonal symmetry directions. A finite-element model was generated using ABAQUS. The agreement between the calculated and measured results is good. Longitudinal residual stresses are strongly tensile (approaching 200 MPa) in the weld, falling to zero at around 15 mm from the weld line with balancing compression towards the edges.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 6 July 2001 / Accepted: 13 November 2001

RID="*"

ID="*"Corresponding author. (Fax: +44-161/295-5060, E-mail: p.j.webster@salford.ac.uk)

Rights and permissions

About this article

Cite this article

Webster, P., Ananthaviravakumar, N., Hughes, D. et al. Measurement and modelling of residual stresses in a TIG weld . Appl Phys A 74 (Suppl 1), s1421–s1423 (2002). https://doi.org/10.1007/s003390201703

Issue Date:

DOI: https://doi.org/10.1007/s003390201703