Abstract

Rebaudioside KA is a diterpene natural sweetener isolated in a trace amount from the leaves of Stevia rebaudiana. Selective glycosylation of rubusoside, a natural product abundantly presented in various plants, is a feasible approach for the biosynthesis of rebaudioside KA. In this study, bacterial glycosyltransferase OleD was identified to selectively transfer glucose from UDPG to 2′-hydroxyl group with a β-1,2 linkage at 19-COO-β-D-glucosyl moiety of rubusoside for the biosynthesis of rebaudioside KA. To eliminate the use of UDPG and improve the productivity, a UDPG regeneration system was constructed as an engineered Escherichia coli strain to couple with the glycosyltransferase. Finally, rubusoside at 22.5 g/L (35.0 mM) was completely converted to rebaudioside KA by the whole cells without exogenous addition of UDPG. This study provides an efficient and scalable method for highly selective biosynthesis of rebaudioside KA.

Similar content being viewed by others

Introduction

Rubusoside (β-D-glucosyl ester of 13-O-β-D-glucosyl-steviol) (1, Fig. 1a) is a safe, stable and low-calorie sweetener, possessing 114-fold more sweetness than sucrose at a concentration of 0.025%1. It was originally isolated from the leaves of Rubus chingii Hu and Rubus suavissimus S. Lee in a high yield (5.3%)2,3. In 2016, rubusoside and various related glycosides were designated as “Generally Recognized as Safe” (GRAS) by the U.S. Food and Drug Administration (FDA). Additionally, it shows a variety of biological activities, including anti-hypertensive, anti-hyperglycaemic, anti-bacterial and anti-inflammation4,5. However, rubusoside exhibits a bitter aftertaste, which greatly undermines its commercial value. To improve the sweetness and the taste of rubusoside, tremendous efforts have been made to search for chemically and enzymatically modified derivatives during the past several decades6,7,8,9,10. Meanwhile, various sugar moieties, such as glucosyl, fructosyl and galactosyl, have been introduced at different hydroxyl groups of rubusoside. Unfortunately, the outcomes have not been satisfactory thus far.

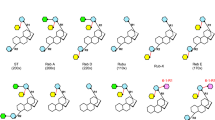

Biosynthesis of rebaudioside KA from rubusoside. (a) Scheme of the glycosylation of rubusoside by OleD. (b) Cascade reaction to couple the glycosylation of target compound (black ellipse) with UDPG regeneration. (c) Schematic diagram for improvement of rebaudioside KA production in E.coli. Abbreviation: OleD, glycosyltransferase; SUS1, sucrose synthase; pyrF, orotidine-5′-phosphate decarboxylase; pgi, glucose-6-phosphate isomerase; ugd, UDPG dehydrogenase; UDPGA, uridine diphosphate glucuronic acid, TCA, tricarboxylic acid.

Rebaudioside KA (2, Fig. 1a), a mono-glycosylated derivative of rubusoside, was isolated in a trace amount from the leaves of Stevia rebaudiana11, which sheds a new light on the discovery of novel natural sweeteners. Rebaudioside KA shows higher sweetness and more pleasant tasting than rubusoside. In particular, rebaudioside KA does not exhibit bitter aftertaste tested by 35 healthy volunteers (unpublished data), which makes it as an ideal candidate for natural sweeteners. Since trace amount of rebaudioside KA has been found only in one plant, the possibility of isolating this compound from natural sources is extremely low. Meanwhile, given the abundance in nature, the commercial availability and the same diterpene skeleton, stereo- and regio-specific glycosylation at 2′-hydroxyl group of C19-COO-β-D-glucosyl moiety of rubusoside could produce rebaudioside KA in a large quantity. Therefore, the exploration of selective glycosylation of rubusoside is a feasible way for the generation of rebaudioside KA.

To date, a variety of enzymes have been used for the glycosylation of rubusoside, including cyclodextrin glycosyltransferase7, β-galactosidases8, β-fructofuranosidase9 and dextransucrase10. Although these enzymes have shown the potential on the glycosylation of rubusoside, low productivity (2.7–66%) and the co-existence of multiple products have been major issues for their usefulness. By contrast, based on the versatility and the flexible binding pockets, UDP-glycosyltransferases (UGTs) could be a class of valuable enzymes to achieve the selective glycosylation of rubusoside to produce rebaudioside KA.

Although UGTs have been used to glycosylate various natural products, such as flavonoids, phenylpropanoids and terpenoids, the absolute requirement of costly sugar donor UDP-glucose (UDPG) has markedly limited their applicability12. To overcome this limitation, UDPG regeneration system has been subsequently developed13,14,15,16, in which UGT is coupled with a sucrose synthase to recycle UDPG with inexpensive sucrose in a cascade reaction (Fig. 1b). Due to the lower intracellular concentration of UDPG (usually 1–2 mM)17, direct regeneration of UDPG in the organisms has been difficult to accomplish. Consequently, various approaches on the engineering of microbial hosts to increase intrinsic UDPG and provide a continuous supply have been explored through the enhancement of natural metabolic pathways18,19,20 or the introduction of heterologous ones21,22. However, these engineered strains have typically resulted in incomplete conversion or low productivity (substrate concentration usually less than 10 mM) for the glycosylation, because current focus on UDPG biosynthesis has mainly dealt with glycolysis, pentose phosphate pathway and glycogen formation18,20. In fact, UTP and UDP are the precursors of UDPG in pyrimidine biosynthetic pathway17, and their availability may also be vital for UDPG biosynthesis. Thus, the efficiency of UDPG regeneration and simultaneous glycosylation could be improved from the increase of UTP and UDP.

In this study, a glycosyltransferase OleD from Streptomyces antibioticus, possessing the capability of glycosylating diverse types of scaffolds to form O-, N- and S-linked glucosides23, was identified to selectively catalyze the conversion of rubusoside to rebaudioside KA. Moreover, a self-sufficient system for UDPG was constructed and optimized in engineered E. coli by coupling OleD with a sucrose synthase (SUS1) to efficiently produce rebaudioside KA without exogenous addition of expensive UDPG (Fig. 1c). The present study offers an opportunity of preparing rebaudioside KA.

Results and Discussion

Enzyme screening and confirmation of the glycosylation of rubusoside

According to previous reports, five UGTs with broad aglycon tolerance, large binding pocket, and potential β-1,2 selectivity were selected for the preparation of β-1,2-mono-glycosylated rubusoside (Supplementary Table S1). These enzymes included YjiC from Bacillus licheniformis24, OleD from Streptomyces antibioticus25, GtfE from Amycolatopsis orientalis26, GtfB from Amycolatopsis orientalis and a chimeric glycosyltransferase GtfAH127. After gene cloning and protein expression (Supplementary Fig. S1), the crude extract containing the glycosylation product was analyzed by HPLC and LC-MS (Supplementary Fig. S2). Among the five enzymes, just OleD and YjiC were able to glycosylate rubusoside. From mass spectrometry analysis, compound 2 ([M − H]− m/z− ~803.37), 3, 4, 5 ([M + Na]+ m/z+ ~827.37) were found to be mono-glycosylated derivatives of rubusoside (C32H50O13, molecular weight ~642.74) respectively. The glycosyltransferase OleD could completely convert rubusoside to compound 2 as a single product, which was quite unusual to any types of glycosylation. Although YjiC was able to simultaneously produce mono-glycosylated compounds 3, 4 and 5, the nature of multiple products severely limited its usefulness. Therefore, compounds 3, 4 and 5 were not isolated for structural determination.

After purification by semi-preparative HPLC, 142 mg of compound 2 were obtained from the reaction mixture and its structure was elucidated by 1D- and 2D-NMR spectroscopy (Supplementary Figs. S3–S9). Compared to reported NMR spectra of rubusoside28, the downfield 13C shift (~4.26 ppm) at C-2′ of C19-COO-β-D-glucosyl moiety and the couple constant (J = 7.8 Hz) of the corresponding anomeric proton indicated that a glucosyl moiety was specifically added to 2′-hydroxyl group of C19-O-glucose of rubusoside in a β-configuration. 1H and 13C NMR spectra of compound 2 (Supplementary Table S2) were in accordance with the data previously reported, thus confirming compound 2 to be rebaudioside KA11. More importantly, given the generation of a single glycosylated product, OleD exhibited exceptional stereo- and regio-selectivity towards rubusoside. In addition, its excellent catalytic efficiency made it to be an ideal enzyme for the glycosylation of rubusoside.

Optimization of glycosylation conditions

To simplify the enzymatic synthesis and improve the yield of rebaudioside KA, a reaction system using crude enzyme extract without extensive protein purification was established. The OleD-catalyzed conversion of rubusoside under different pH (6.0–12.0), temperature (15–40 °C), rubusoside concentration (7.5–25 g/L), molar ratio of rubusoside/UDPG (1:1–1:8) and reaction time (2–24 h) were compared to optimize the glycosylation conditions (Supplementary Fig. S10 and Fig. 2). The highest conversion of rubusoside was achieved in 50 mM sodium phosphate (pH 11.0) buffer at 35 °C. The rubusoside/UDPG molar ratio was found to be optimal at 1:6. When the concentration of rubusoside increased from 7.5 g/L to 25 g/L, the conversion decreased from 98.0% to 88.5%, and then rapidly declined to 29.5% (Supplementary Fig. S10). Subsequently, the time course for rebaudioside KA production from rubusoside was monitored at different substrate concentrations (10, 15 and 20 g/L) under the optimized conditions. As shown in Fig. 2, rebaudioside KA could be efficiently biosynthesized during the first 10 h. After 24 h of reaction, 10 g/L and 15 g/L rubusoside were completely glycosylated (>95%), whereas 54.3% of rubusoside was converted at concentration of 20 g/L. At high substrate concentrations, the accumulation of UDP during the reaction could be an important factor for the suppression of the catalytic efficiency and the promotion of reverse glycosylation29. Although OleD could completely convert 15 g/L rubusoside to rebaudioside KA, the addition of costly UDPG markedly prohibited its practical application.

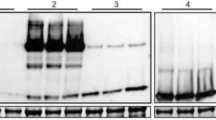

Construction of the E. coli strain for the regeneration of UDPG

To reduce the use of expensive UDPG, a UDPG regeneration system coupling with the glycosylation by OleD was constructed in E. coli cells. Given the poor stability and the difficulty on the quantification of UDPG in the dynamic system, the regeneration efficiency was evaluated based on the production of rebaudioside KA from rubusoside by E. coli cells. Firstly, the genes of OleD and a widely used sucrose synthase (SUS1) from Arabidopsis thaliana were synthesized and constructed in pETDuet-1 vector preceded by a T7 promoter/lac operon. To compare the effects of cloning order on regeneration efficiency, two genes were inserted into different multiple cloning sites to yield recombinant plasmids pAT-GT and pGT-AT respectively. These two constructs were expressed in E. coli BL21(DE3), and the corresponding strains E. coli C-1 and C-2 (Supplementary Fig. S11a) were incubated in a mixture of 2 g/L rubusoside and 600 g/L sucrose, with the supply of UDPG (molar ratio of rubusoside/UDPG = 1:0.5) for the initiation of the UDPG recycling. E. coli C-1 showed higher conversion than C-2 (Fig. 3). Thus, C-1 strain was selected for subsequent experiments.

To examine whether the amount of UDPG could be reduced, the efficiency of the whole cell system was compared with different amounts of UDPG and sucrose. As shown in Fig. 4, when the concentration of sucrose reached 700 g/L and the molar ratio of rubusoside/UDPG = 1:1.5, 2 g/L rubusoside could be completely converted to rebaudioside KA, decreasing the demand for UDPG by 75%. The requirement of high concentrations of sucrose might be due to its high Km value for sucrose synthase when expressed in prokaryotic hosts30. Since the activities of OleD and sucrose synthase are strongly pH-dependent but they present distinct optimal pH values31, a lower conversion as shown in Fig. 4 was not surprising. In addition, the conversion of 2 g/L rubusoside in the OleD-SUS1 cascade system was only 10.0% in the absence of UDPG, suggesting that the introduction of sucrose synthase was not enough to drive UDPG regeneration. Thus, further engineering of the host and optimization of whole-cell reaction is required.

Improvement of metabolic flux toward UDPG synthesis

Given the low conversion with the heterologous expression of sucrose synthase and the supply of sucrose, we supposed that lower intrinsic amount of UDP may result in a low efficiency on UDPG regeneration and the simultaneous bioconversion. UDP is primarily synthesized from the pyrimidine metabolic pathway in E. coli32, in which orotate phosphoribosyltransferase (pyrE) and orotidine-5′-phosphate decarboxylase (pyrF) are involved in UMP biosynthesis from orotate, while uridylate kinase (pyrH) catalyzes the phosphorylation of UMP to UDP (Fig. 5a). Therefore, enhancement of the pyrimidine biosynthetic pathway through fine-tuning the metabolic flux should promote UDPG production. To test our hypothesis, these upstream enzymes were individually overexpressed in E. coli strain C-1 to yield recombinant strains of CP-1, CP-2 and CP-3 respectively (Supplementary Fig. S11b). Among these strains, CP-2 showed a better conversion, possibly due to the fact that pyrF catalyzes the irreversible reaction with UMP formation. After 12 h, CP-2 strain converted 2 g/L rubusoside to rebaudioside KA with a conversion of 45.5%, significantly higher than that of C-1 (Fig. 5b). However, when pyrE, pyrF and pyrH were co-expressed in C-1 strain, the conversion was unexpectedly lower than that of CP-2 (Supplementary Fig. S12), suggesting that the pyrimidine metabolic pathway is more complicated than current knowledge and requires further clarification.

Construction of redirected carbon metabolic pathways for UDPG biosynthesis. (a) Engineering strategies for broadening the metabolic flux toward UDPG biosynthesis in E. coli C-1. Overexpressed genes are shown in red and deleted genes are shown in blue with italic, (Δ) represents gene knock-out. The glycolysis, pyrimidine metabolism and regeneration cycle are expressed by gray, blue, and green rounded rectangles, respectively. Abbreviations: F6P, fructose-6-phosphate; TCA, tricarboxylic acid; G6P, glucose-6-phosphate PRPP, 5-phosphoribosyl-1-pyrophosphate; UMP, uridine monophosphate; UDP, uridine diphosphate; UTP, uridine triphosphate; UDPG, uridine diphosphate glucose; UDPGA, uridine diphosphate glucuronic acid; KA, rebaudioside KA; Ru, rubusoside; Suc, sucrose; Fru, fructose; G1P, glucose-1-phosphate. (b) Comparison of rubusoside conversion by the engineered strains. **p < 0.01 and ***P < 0.001 indicate the statistical significances between different groups.

Besides enhancing the UDP biosynthetic pathway, redistribution of carbon flux should be advantageous for the UDPG regeneration. As previously known, glucose-6-phosphate (G6P) is crucial in directing carbon source to glycolysis, pentose phosphate pathway, and the conversion to glucose-1-phosphate (G1P) (Fig. 5a). Knockout of G6P isomerase (pgi) could accumulate UDPG by increasing the G6P pool through the elimination of acetate formation and the excessive metabolism of E. coli33,34. Thus, compared to the reference strain CP-2, the conversion of rubusoside showed 50% higher in the pgi-deleted E. coli strain (CPM-1), in which the glycolysis pathway was blocked (Fig. 5b).

The decreasing of the metabolic consumption of UDPG represents another way to increase the availability of intracellular UDPG. Because UDP-glucose dehydrogenase (ugd) is a major enzyme for UDPG degradation35, an E. coli strain (CPM-2) was created by deleting ugd in CPM-1, resulting in the increasing of rubusoside conversion to 94.0% without UDPG addition (Fig. 5b). These results confirmed that an UDPG self-sufficient E. coli strain was successfully constructed. By introducing the glycosyltransferase OleD, rubusoside at 2 g/L was completely converted to rebaudioside KA without the addition of UDPG, which may reflect the collective contribution of the blockage of glycolysis, the increasing of UDP formation, and the prevention of UDPG degradation in E. coli.

Maximization of UDPG self-sufficient system for rebaudioside KA production

The engineered E. coli strain (CPM-2) was then used to perform the bioconversion for rebaudioside KA. To maximize the efficiency for the obtainment of rebaudioside KA, the reaction parameters involved in the biosynthesis were further optimized, including temperature, pH, sucrose concentration, rubusoside concentration and bacterial biomass. Firstly, sucrose (700 g/L), rubusoside (12.5 g/L) and bacterial biomass (25 g/L) in a total volume of 1 mL were used for the evaluation of temperature (25–55 °C) and pH (5.5–10.0). The optimal conditions of 40 °C and pH 7.0 were obtained (Supplementary Fig. S13). Then, we designed a three-factor five-level orthogonal experiment to analyze the influence of sucrose, rubusoside and biomass on the production of rebaudioside KA (Supplementary Tables S3 and S4). The results of the orthogonal experiment were examined by variance analysis (Supplementary Table S5). Based on F and P values, the significant influencing factors were sucrose and bacterial biomass, and rubusoside had the least effect on the product yield. From the estimated marginal means of factors (Supplementary Table S6), the optimal combination for the highest production was 800 g/L sucrose, 22.5 g/L rubusoside and 100 g/L bacterial biomass, which was subsequently confirmed experimentally at a larger scale.

The whole cell bioconversion was carried out in M9 medium (pH 7.0) containing 800 g/L sucrose, 22.5 g/L rubusoside and 100 g/L bacterial biomass in a 200 mL volume at 40 °C, 220 rpm for 20 h. During the glycosylating process, samples were taken every 2 h for HPLC analysis to calculate the conversion of rubusoside. After 18 h of the reaction, rubusoside was completely converted to rebaudioside KA (>95%) (Fig. 6), demonstrating the compatibility between the UDPG regeneration system and the selective glycosylation by glycosyltransferase OleD. Compared to other UDP-glycosyltransferases coupled with different UDPG regeneration approaches for the glycosylation of various natural products12,31, the present method has showed obvious advantages on substrate concentration and productivity.

Conclusion

Glycosyltransferase OleD was identified to selectively glycosylate rubusoside for the generation of rebaudioside KA. An engineered E. coli strain of CPM-2 was constructed to regenerate UDPG. In addition to the blockage of glycolysis and the prevention of UDPG degradation, the increasing of the biosynthetic precursors of UDPG was confirmed to be important for the regeneration of UDPG in E. coli cells. By coupling glycosyltransferase OleD with the engineered E. coli strain, rebaudioside KA could be efficiently produced from rubusoside at 22.5 g/L (35.0 mM) substrate concentration without exogeneous addition of UDPG. The present glycosyltransferase-UDPG regeneration system can completely eliminate the use of UDPG and enable the selective and efficient biosynthesis of various food-related glycosides.

Materials and methods

Chemical and biological materials

Rubusoside (purity 92%) was purchased from Tongtian Biotechnology Co., Ltd. (Shanghai, China). UDPG (purity 98%) was purchased from Ruixin Biotech Co. (Suzhou, China). All strains and plasmids used in this study are listed in Supplementary Table S7. Plasmids were constructed according to the standard protocols36. All PCR primers used for gene cloning were synthesized by GENEWIZ Co. (Suzhou, China) and are listed in Supplementary Table S8. The nucleotide sequences of codon-optimized UGTs (YjiC, OleD, GtfE, GtfB, GtfAH1) and SUS1 were synthesized by GENEWIZ. Gene deletion strains of E. coli BL21(DE3) were obtained using λ-Red deletion method37.

Protein expression and functional verification of selected glycosyltransferases

The plasmids pET-302 or pET-22b (+) containing glycosyltransferase genes were respectively transformed into E. coli BL21(DE3). The recombinant strains were grown in Luria-Bertani (LB) medium containing 100 μg/mL ampicillin at 37 °C. Protein expression was performed according to previous report25. Cells were harvested by centrifugation at 5, 000 × g for 10 min and resuspended in 50 mM Tris-HCl buffer (pH 8.0). The cells were lysed by sonication on ice and the pellets were removed by centrifugation. The crude extracts were analyzed by SDS-PAGE.

The glycosylation of rubusoside by the selected UGTs was verified using the crude extracts of the recombinant cells. Reaction mixtures containing 600 μL crude extract, 2 g/L rubusoside and 7.8 g/L UDPG were incubated at 30 °C, 220 rpm for 12 h. The reactions were terminated by adding an equal volume of methanol. After centrifugation at 10, 000 × g for 10 min, the reaction mixtures were analyzed by HPLC on Agilent 1260 Infinity with a YMC-C18 column (250 mm × 4.6 mm; 5 μm). Analysis was performed at 35 °C with UV detection at 210 nm by water (containing 0.1% formic acid, solvent A) and acetonitrile (containing 0.1% formic acid, solvent B) at a flow rate of 1.0 mL/min under following gradient: 10%-90% solvent B for 25 min. LC-MS was performed at negative or positive ion mode on Agilent LC1200/MS Q-TOF 6520.

Preparation and structural elucidation of rebaudioside KA

To elucidate the structure of mono-glycosylated rubusoside, the reaction was performed at 200 mL with the same conditions described above. The reaction was stopped by adding twice volume of methanol and centrifuged at 10, 000 × g for 10 min. Methanol and a part of water were removed under reduced pressure at 42 °C. The residual supernatant was lyophilized for 48 h. Subsequently, the lyophilized powder was dissolved in water and purified by Waters Prep150 semi-preparative HPLC. The purified product was dissolved in DMSO-d6 at a final concentration of 20 mg/mL and the structure was elucidated by 1D- and 2D-NMR.

Optimization of enzymatic reaction conditions

The standard reaction of OleD with rubusoside was performed in 1 mL crude extract reaction mixtures containing 50 mM sodium phosphate (pH 11.0), 15 g/L rubusoside, 58.6 g/L UDPG (molar ratio of rubusoside/UDPG = 1:4) and incubated at 30 °C for 12 h. For pH optimization, 50 mM sodium phosphate, 50 mM Tris-HCl, 50 mM glycine-NaOH were used for the range of pH from 6.0 to 12.0. The optimal temperature was examined ranging from 15 °C to 40 °C. The concentration of rubusoside was investigated ranging from 7.5–25 g/L. The optimal molar ratio of rubusoside/UDPG was compared ranging from 1:1 to 1:8. For the optimization of reaction time, reaction was performed under the optimized conditions. The conversion (%) of rubusoside to rebaudioside KA was calculated as following: conversion (%) = CKA/CRu, where CKA represents the rebaudioside KA molar concentration during the reaction, CRu represents the initial rubusodide molar concentration.

Whole-cell bioconversion

The engineered E. coli strains (C-1, C-2, CP-1, CP-2, CP-3, CPM-1, CPM-2) were respectively grown in LB medium containing appropriate antibiotics at 37 °C until OD600 = 0.8–1.0. IPTG was added at a final concentration of 1 mM, and protein expression was induced at 37 °C for 10 h. The cells were harvested by centrifugation at 5, 000 × g for 10 min. The pellet was resuspended in a modified M9 medium (pH 6.5) containing 12.8 g/L Na2HPO4·7H2O, 3 g/L KH2PO4, 0.5 g/L NaCl, 1 g/L NH4Cl and 2 mM MgCl2. Whole cells with UDPG and sucrose at different concentrations and 2 g/L rubusoside in a total volume of 1 mL (bacterial biomass 25 g/L) were incubated at 35 °C, 220 rpm for 12 h. All reactions were stopped by adding twice volume of methanol, and the products were analyzed by HPLC. All data are represented as the means of three independent experiments with standard deviations; Student T-test was applied for the comparison of mean values between two groups (*p < 0.05, **p < 0.01 and ***P < 0.001 indicate the statistical significances between different groups).

Orthogonal experiment

To determine the optimal combination for rubusoside conversion in whole-cell reactions, concentrations of sucrose (500, 600, 700, 800, 900 g/L), rubusoside (15, 17.5, 20, 22.5, 25 g/L), and bacterial biomass (25, 50, 75, 100, 125 g/L) were tested though the orthogonal experiment. Firstly, 25 combinations were obtained using orthogonal array design L25 (53). The different combination was mixed in 1 mL M9 medium (pH 7.0) and performed at 40 °C, 220 rpm for 12 h. The reactions were terminated with methanol and subjected to HPLC analysis. Subsequently, the production of rebaudioside KA as dependent variable was analyzed by variance analysis, which was conducted using IBM SPSS statistics 22.0 software based on the main effect model.

References

Ko, J.-A. et al. Mass production of rubusoside using a novel stevioside-specific β-glucosidase from Aspergillus aculeatus. J. Agric. Food Chem. 60, 6210–6216 (2012).

Tanaka, T. et al. Rubusoside (β-D-glucosyl ester of 13-O-β-D-glucosyl-steviol), a sweet principle of Rubus chingii Hu (Rosaceae). Agric. Biol. Chem. 45, 2165–2166 (1981).

Chou, W.-H. et al. Diterpene glycosides from leaves of Chinese Rubus chingii and fruits of R.suavissimus, and identification of source plant of the chinease folk medicine “Fu-pen-zi.”. Chem. Pharm. Bull. 35, 3021–3024 (1987).

Lemus-Mondaca, R., Vega-Gálvez, A., Zura-Bravo, L. & Ah-Hen, K. Stevia rebaudiana Bertoni, source of a high-potency natural sweetener: A comprehensive review on the biochemical, nutritional and functional aspects. Food Chem. 132, 1121–1132 (2012).

Chu, J., Zhang, T. & He, K. Cariogenicity features of Streptococcus mutans in presence of rubusoside. BMC Oral Health 16, 54 (2016).

Kaneda, N., Kasai, R., Yamasaki, K. & Tanaka, O. Chemical studies on sweet diterpene-glycosides of Stevia rebaudiana: Conversion of Stevioside into Rebaudioside-A. Chem. Pharm. Bull. 25, 2466–2467 (1977).

Darise, M. et al. Enzymic transglucosylation of rubusoside and the structure-sweetness relationship of steviol-bisglycosides. Agric. Biol. Chem. 48, 2483–2488 (1984).

Kitahata, S., Ishikawa, H., Miyata, T. & Tanaka, O. Production of rubusoside derivatives by transgalactosylation of various β-galactosidases. Agric. Biol. Chem. 53, 2929–2934 (1989).

Ishikawa, H., Kitahata, S., Ohtani, K., Ikuhara, C. & Tanaka, O. Production of stevioside and rubusoside derivatives by transfructosylation of β-fructofuranosidase. Agric. Biol. Chem. 54, 3137–3143 (1990).

Ko, J.-A. et al. Glucosyl rubusosides by dextransucrases improve the quality of taste and sweetness. J. Microbiol. Biotechnol. 26, 493–497 (2016).

Ibrahim, M. A. et al. Minor diterpene glycosides from the leaves of stevia rebaudiana. J. Nat. Prod. 77, 1231–1235 (2014).

De Bruyn, F., Maertens, J., Beauprez, J., Soetaert, W. & De Mey, M. Biotechnological advances in UDP-sugar based glycosylation of small molecules. Biotechnol. Adv. 33, 288–302 (2015).

Wang, Y. et al. Efficient enzymatic production of rebaudioside A from stevioside. Biosci. Biotechnol. Biochem. 80, 67–73 (2016).

Chen, L. et al. Synthesis of rebaudioside D, using glycosyltransferase UGTSL2 and in situ UDP-glucose regeneration. Food Chem. 259, 286–291 (2018).

Liu, F., Ding, F., Shao, W., He, B. & Wang, G. Regulated preparation of Crocin-1 or Crocin-2′ triggered by the cosolvent DMSO using Bs-GT/At-SuSy one-pot reaction. J. Agric. Food Chem. 67, 12496–12501 (2019).

Thapa, S. B., Pandey, R. P., Bashyal, P., Tokutaro, T. & Sohng, J. K. Cascade biocatalysis systems for bioactive naringenin glucosides and quercetin rhamnoside production from sucrose. Appl. Microbiol. Biotechnol. 103, 7953–7969 (2019).

Mao, Z., Shin, H. D. & Chen, R. R. Engineering the E. coli UDP-glucose synthesis pathway for oligosaccharide synthesis. Biotechnol. Prog. 22, 369–374 (2006).

Thuan, N. H., Park, J. W. & Sohng, J. K. Toward the production of flavone-7-O-β-D-glucopyranosides using Arabidopsis glycosyltransferase in Escherichia coli. Process Biochem. 48, 1744–1748 (2013).

Parajuli, P., Pandey, R. P., Trang, N. T. H., Chaudhary, A. K. & Sohng, J. K. Synthetic sugar cassettes for the efficient production of flavonol glycosides in Escherichia coli. Microb. Cell Fact. 14, 76 (2015).

Yang, Y. et al. Systems metabolic engineering of: Escherichia coli to enhance the production of flavonoid glucuronides. RSC Adv. 6, 33622 (2016).

De Bruyn, F. et al. Development of an in vivo glucosylation platform by coupling production to growth: Production of phenolic glucosides by a glycosyltransferase of Vitis vinifera. Biotechnol. Bioeng. 112, 1594–1603 (2015).

Pei, J. et al. Efficient biotransformation of luteolin to isoorientin through adjusting induction strategy, controlling acetic acid, and increasing UDP-glucose supply in Escherichia coli. J. Agric. Food Chem. 67, 331–340 (2019).

Gantt, R. W., Goff, R. D., Williams, G. J. & Thorson, J. S. Probing the aglycon promiscuity of an engineered glycosyltransferase. Angew. Chemie Int. Ed 47, 8889–8892 (2008).

Gurung, R. B., Kim, E.-H., Oh, T.-J. & Sohng, J. K. Enzymatic synthesis of apigenin glucosides by glucosyltransferase (YjiC) from Bacillus licheniformis DSM 13. Mol. Cells 36, 355–361 (2013).

Williams, G. J., Zhang, C. & Thorson, J. S. Expanding the promiscuity of a natural-product glycosyltransferase by directed evolution. Nat. Chem. Biol. 3, 657–662 (2007).

Losey, H. C. et al. Tandem action of glycosyltransferases in the maturation of vancomycin and teicoplanin aglycones: Novel glycopeptides. Biochemistry 40, 4745–4755 (2001).

Truman, A. W. et al. Chimeric glycosyltransferases for the generation of hybrid glycopeptides. Chem. Biol. 16, 676–685 (2009).

Sugimoto, N. et al. Analysis of rubusoside and related compounds in tenryocha extract sweetener. J. Food Hyg. Soc. Japan 43, 250–253 (2002).

Masada, S. et al. An efficient chemoenzymatic production of small molecule glucosides with in situ UDP-glucose recycling. FEBS Lett 581, 2562–2566 (2007).

Römer, U. et al. Expression, purification and characterization of recombinant sucrose synthase 1 from Solanum tuberosum L. for carbohydrate engineering. J. Biotechnol. 107, 135–149 (2004).

Schmölzer, K., Gutmann, A., Diricks, M., Desmet, T. & Nidetzky, B. Sucrose synthase: A unique glycosyltransferase for biocatalytic glycosylation process development. Biotechnol. Adv. 34, 88–111 (2016).

O’Donovan, G. A. & Neuhard, J. Pyrimidine metabolism in microorganisms. Bacteriol. Rev 34, 278–343 (1970).

Eiteman, M. A. & Altman, E. Overcoming acetate in Escherichia coli recombinant protein fermentations. Trends Biotechnol. 24, 530–536 (2006).

Usui, Y. et al. Investigating the effects of perturbations to pgi and eno gene expression on central carbon metabolism in Escherichia coli using 13C metabolic flux analysis. Microb. Cell Fact. 11, 87 (2012).

Roman, E., Roberts, I., Lidholt, K. & Kusche-Gullberg, M. Overexpression of UDP-glucose dehydrogenase in Escherichia coli results in decreased biosynthesis of K5 polysaccharide. Biochem. J 374, 767–772 (2003).

Green, M. R. & Sambrook, J. Molecular Cloning: A Laboratory Manual. 4rd ed. (Cold Spring Harbor Laboratory Press, NY, 2012).

Datsenko, K. A. & Wanner, B. L. One-step inactivation of chromosomal genes in Escherichia coli K-12 using PCR products. Proc. Natl. Acad. Sci. U. S. A. 97, 6640–6645 (2000).

Acknowledgements

This work was supported by the grants of the National Key R&D Program of China (2018YFA0902000), the National Natural Science Foundation of China (No. 21778076), the “111 Project” from the Ministry of Education of China and the State Administration of Foreign Expert Affairs of China (No. 111-2-07), the “Double First-Class” University project (CPU2018GY36) and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX19_0659).

Author information

Authors and Affiliations

Contributions

Y.C. and X.W. conceived and designed the study. Y.Z., S.X., Y.J. and Y.D. performed the experiments. Y.Z., S.X. and X.W. analyzed the data. Y.Z. and Y.C. wrote the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, Y., Xu, S., Jin, Y. et al. Efficient Biocatalytic Preparation of Rebaudioside KA: Highly Selective Glycosylation Coupled with UDPG Regeneration. Sci Rep 10, 6230 (2020). https://doi.org/10.1038/s41598-020-63379-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-63379-9

This article is cited by

-

Transglycosylation of Stevioside by a Commercial β-Glucanase with Fungal Extracted β-Glucans as Donors

Waste and Biomass Valorization (2023)

-

De novo biosynthesis of rubusoside and rebaudiosides in engineered yeasts

Nature Communications (2022)

-

Evaluation of double expression system for co-expression and co-immobilization of flavonoid glucosylation cascade

Applied Microbiology and Biotechnology (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.