Abstract

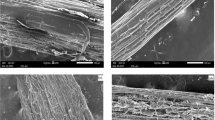

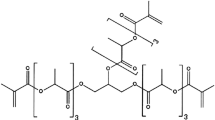

Safety glazing is a type of laminated glazing that holds together when shattered, due to the presence of an interlayer usually made of polyvinyl butyral (PVB). It is widely used in industrial application where the glazing could fall, or become a projectile to avoid serious injuries to humans after an impact with a foreign object. To replace the PVB, we have developed a modified cellulose nanofibers (NFC) by grafting poly(glycidyl methacrylate) with glycerol addition. This modification has improved the NFC pure performance as well as their compatibility with polar polymers. Therefore, this study reports the preparation and characterization of laminated glazing with composites of PVB reinforced with 40, 50 and 70% by weight of modified NFC. Composites interlayers are very transparent (up to 93% light transmission) with an interesting light character (up to 18.72% weight loss) in comparison to a PVB interlayer only. The chosen laminated glazing have been characterized by quasi-static (three-point bending) and dynamic impact loading (drop weight test). The quasi-static show the force–displacement curves of glazing while the dynamic testing give the energy absorption capability and maximum impact force. In our testing, the glazing with modified NFC have shown increased mechanical properties. Moreover, the laminated glazing made with an interlayer reinforced with 40% NFC exhibits the highest impact properties with a maximum force at break of 36,270 N and 24.81 J of absorbed energy. This study has shown that the modified NFC is indeed a lighter and environment-friendlier alternative for laminated glazing.

Similar content being viewed by others

Data availability

Not applicable for that section.

Code availability

Not applicable for that section.

References

ASTM Standards: D790. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. http://mahshahr.aut.ac.ir/lib/exe/fetch.php?media=labs:astm_d790.pdf

Cha YJ, Lee CH, Choe S (1998) Morphology and mechanical properties of nylon 6 toughened with waste poly(vinyl butyral) film. J Appl Polym Sci 67(9):1531–1540

Davies GAO, Olsson R (2004) Impact on composite structures. Aeronaut J 108(1089):541–563

Enayati MS, Behzad T, Sajkiewicz P, Bagheri R, Ghasemi-Mobarakeh L, Łojkowski W, Pahlevanneshan Z, Ahmadi M (2016) Crystallinity study of electrospun poly(vinyl alcohol) nanofibers: effect of electrospinning, filler incorporation, and heat treatment. Iran Polym J 25(7):647–659

Galuppi L, Royer-Carfagni G (2014) Enhanced effective thickness of multi-layered laminated glass. Compos B Eng 64:202–213

Gao W, Wang R, Chen S, Zang M (2019) An intrinsic cohesive zone approach for impact failure of windshield laminated glass subjected to a pedestrian headform. Int J Impact Eng 126:147–159

Government of Canada (2018) Vehicle weight. https://www.nrcan.gc.ca/energy/efficiency/energy-efficiency-transportation-and-alternative-fuels/choosing-right-vehicle/tips-buying-fuel-efficient-vehicle/factors-affect-fuel-efficiency/vehicle-weight/21024. Accessed 20 Oct 2020

Grethe T, Schwarz-Pfeiffer A, Grassmann C, Engelhardt E, Feld S, Guo F, De Vrieze M, Mahltig B (2018) Chapter 5-Polyvinylbutyral (PVB) coatings for optical modification of textile substrates. In: Mendez Vilas A (ed) Polymer research: communicating current advances, contributions, applications and educational aspects. 1st, Formatex Research Center S.L., Madrid, pp 36–45

Huang X, Lin Y, Fang G (2018) Thermal properties of polyvinyl butyral/graphene composites as encapsulation materials for solar cells. Sol Energy 161:187–193

Immarigeon JP, Holt RT, Koul AK, Zhao L, Wallace W, Beddoes JC (1995) Lightweight materials for aircraft applications. Mater Charact 35(1):41–67

Joost WJ (2012) Reducing vehicle weight and improving US energy efficiency using integrated computational materials engineering. JOM 64(9):1032–1038

Kannivel S, Subramanian H, Arumugam V, Dhakal HN (2020) Low-velocity impact induced damage evaluation and its influence on the residual flexural behavior of glass/epoxy laminates hybridized with glass fillers. J Compos Sci 4(3):99

Khan BA, Na H, Chevali V, Warner P, Zhu J, Wang H (2018) Glycidyl methacrylate-compatibilized poly(lactic acid)/hemp hurd biocomposites: processing, crystallization, and thermo-mechanical response. J Mater Sci Technol 34(2):387–397

LaMotte J, Ridder Iii W, Yeung K, De Land P (2000) Effect of aftermarket automobile window tinting films on driver vision. Hum Factors 42(2):327–336

Lassoued M, Crispino F, Loranger É (2020) Design and synthesis of transparent and flexible nanofibrillated cellulose films to replace petroleum-based polymers. Carbohydr Polym (accepted with minor corrections)

Loranger É, Paquin M, Daneault C, Chabot B (2011) Comparative study of sonochemical effects in an ultrasonic bath and in a large-scale flow-through sonoreactor. Chem Eng J 178:359–365

Martín M, Centelles X, Solé A, Barreneche C, Fernández AI, Cabeza LF (2020) Polymeric interlayer materials for laminated glass: a review. Constr Build Mater 230:116897

Maury C, Crispino F, Loranger É (2019) Preliminary study of laminated glass with nanocellulose and poly(vinyl butyral) for safety glazing. BioResources 14(2):4157–4170

Miraftab M, Saifullah AN, Çay A (2015) Physical stabilization of electrospun poly(vinyl alcohol) nanofibers: comparative study on methanol and heat-based crosslinking. J Mater Sci 50:4174–4186

Paquin M, Loranger É, Hannaux V, Chabot B, Daneault C (2013) The use of Weissler method for scale-up a Kraft pulp oxidation by TEMPO-mediated system from a batch mode to a continuous flow-through sonoreactor. Ultrason Sonochem 20(1):103–108

Pariafsai F (2016) A review of design considerations in glass buildings. Front Archit Res 5(2):171–193

Rattaz A, Mishra SP, Chabot B, Daneault C (2011) Cellulose nanofibres by sonocatalysed-TEMPO-oxidation. Cellulose 18(3):585–593

Acknowledgments

The research work was supported financially by the Mathematics of Information Technology and Complex Systems (MITACS NCE) and the Natural Sciences and Engineering Research Council of Canada (NSERC).

Funding

The Mathematics of Information Technology and Complex Systems (MITACS NCE) and The Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Contributions

ML: Methodology, Validation, Investigation, Data curation, Formal analysis, Writing—original draft, Visualization. FC: Conceptualization, Cosupervision, Writing—review & editing. EL: Conceptualization, Project administration, Supervision, Writing—review & editing, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lassoued, M., Crispino, F. & Loranger, É. Making security glazing from modified TEMPO oxidized nanofibers and poly vinylbutyral. Cellulose 28, 3017–3027 (2021). https://doi.org/10.1007/s10570-021-03761-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03761-6