Abstract

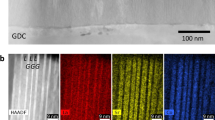

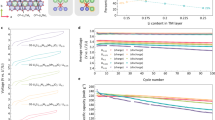

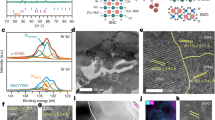

Electrode materials for intermediate temperature (500–700 ∘C) solid oxide fuel cells require electrical and mechanical stability to maintain performance during the cell lifetime. This has proven difficult to achieve for many candidate cathode materials and their derivatives with good transport and electrocatalytic properties because of reactivity towards cell components, and the fuels and oxidants. Here we present Ba0.5Sr0.5(Co0.7Fe0.3)0.6875W0.3125O3−δ (BSCFW), a self-assembled composite prepared through simple solid state synthesis, consisting of B-site cation ordered double perovskite and disordered single perovskite oxide phases, as a candidate cathode material. These phases interact by dynamic compositional change at the operating temperature, promoting both chemical stability through the increased amount of W in the catalytically active single perovskite provided from the W-reservoir double perovskite, and microstructural stability through reduced sintering of the supported catalytically active phase. This interactive catalyst-support system enabled stable high electrochemical activity through the synergic integration of the distinct properties of the two phases.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Irvine, J. T. S. et al. Evolution of the electrochemical interface in high-temperature fuel cells and electrolysers. Nat. Energy 1, 15014 (2016).

Yokokawa, H. Towards comprehensive description of stack durability/reliability behavior. Fuel Cells 15, 652–668 (2015).

Zhang, X. et al. A review of integration strategies for solid oxide fuel cells. J. Power Sources 195, 685–702 (2010).

Kilner, J. A. & Burriel, M. Materials for intermediate-temperature solid-oxide fuel cells. Annu. Rev. Mater. Res. 44, 365–393 (2014).

Aguadero, A. et al. Materials development for intermediate-temperature solid oxide electrochemical devices. J. Mater. Sci. 47, 3925–3948 (2012).

Lee, K. T. & Wachsman, E. D. Role of nanostructures on SOFC performance at reduced temperatures. MRS Bull. 39, 783–791 (2014).

Gao, Z., Mogni, L. V., Miller, E. C., Railsback, J. G. & Barnett, S. A. A perspective on low-temperature solid oxide fuel cells. Energy Environ. Sci. 9, 1602–1644 (2016).

Kendrick, E. & Slater, P. R. Battery and solid oxide fuel cell materials. Annu. Rep. Prog. Chem. A 109, 396–420 (2013).

Shao, Z. & Haile, S. M. A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 431, 170–173 (2004).

Steele, B. C. H. & Heinzel, A. Materials for fuel-cell technologies. Nature 414, 345–352 (2001).

Demont, A. et al. Single sublattice endotaxial phase separation driven by charge frustration in a complex oxide. J. Am. Chem. Soc. 135, 10114–10123 (2013).

Jung, J.-I. & Edwards, D. X-ray photoelectron study on Ba0.5Sr0.5CoFe1−xO3−δ (BSCF: x = 0.2 and 0.8) ceramics annealed at different temperature and pO2. J. Mater. Sci. 46, 7415–7422 (2011).

Yan, A. et al. Investigation of a Ba0.5Sr0.5Co0.8Fe0.2O3−δ based cathode IT-SOFC: I. The effect of CO2 on the cell performance. Appl. Catal. B 66, 64–71 (2006).

Yan, A., Maragou, V., Arico, A., Cheng, M. & Tsiakaras, P. Investigation of a Ba0.5Sr0.5Co0.8Fe0.2O3−δ based cathode SOFC: II. The effect of CO2 on the chemical stability. Appl. Catal. B 76, 320–327 (2007).

Wang, K. et al. Properties and performance of Ba0.5Sr0.5Co0.8Fe0.2O3−δ + Sm0.2Ce0.8O1.9 composite cathode. J. Power Sources 179, 60–68 (2008).

Patra, H., Rout, S. K., Pratihar, S. K. & Bhattacharya, S. Thermal, electrical and electrochemical characteristics of Ba1−xSrxCo0.8Fe0.2O3−δ cathode material for intermediate temperature solid oxide fuel cells. Int. J. Hydrog. Energy 36, 11904–11913 (2011).

Li, S., Lü, Z., Huang, X. & Su, W. Thermal, electrical, and electrochemical properties of Nd-doped Ba0.5Sr0.5Co0.8Fe0.2O3−δ as a cathode material for SOFC. Solid State Ion. 178, 1853–1858 (2008).

Kharton, V. V. et al. Ceria-based materials for solid oxide fuel cells. J. Mater. Sci. 36, 1105–1117 (2001).

Sameshima, S., Ichikawa, T., Kawaminami, M. & Hirata, Y. Thermal and mechanical properties of rare earth-doped ceria ceramics. Mater. Chem. Phys. 61, 31–35 (1999).

Shannon, R. D. & Prewitt, C. T. Effective ionic radii in oxides and fluorides. Acta Crystallogr. B 25, 925–946 (1969).

Wells, A. F. Structural Inorganic Chemistry (Oxford Univ. Press, 1984).

Popov, M. P., Starkov, I. A., Bychkov, S. F. & Nemudry, A. P. Improvement of Ba0.5Sr0.5Co0.8Fe0.2O3−δ functional properties by partial substitution of cobalt with tungsten. J. Membr. Sci. 469, 88–94 (2014).

Itoh, T. et al. Determination of the crystal structure and charge density of (Ba0.5Sr0.5)(Co0.8Fe0.2)O2.33 by Rietveld refinement and maximum entropy method analysis. Solid State Commun. 149, 41–44 (2009).

Chen, Z., Ran, R., Zhou, W., Shao, Z. & Liu, S. Assessment of Ba0.5Sr0.5Co1−yFeyO3−δ (y = 0.0–1.0) for prospective application as cathode for IT-SOFCs or oxygen permeating membrane. Electrochim. Acta 52, 7343–7351 (2007).

McIntosh, S., Vente, J. F., Haije, W. G., Blank, D. H. A. & Bouwmeester, H. J. M. Structure and oxygen stoichiometry of SrCo0.8Fe0.2O3−δ and Ba0.5Sr0.5Co0.8Fe0.2O3−δ . Solid State Ion. 177, 1737–1742 (2006).

Lim, Y. H., Lee, J., Yoon, J. S., Kim, C. E. & Hwang, H. J. Electrochemical performance of Ba0.5Sr0.5CoxFe1−xO3−δ (x = 0.2–0.8) cathode on a ScSZ electrolyte for intermediate temperature SOFCs. J. Power Sources 171, 79–85 (2007).

Bi, L., Fabbri, E. & Traversa, E. Novel Ba0.5Sr0.5(Co0.8Fe0.2)(1−x)TixO3−δ (x = 0, 0.05, and 0.1) cathode materials for proton-conducting solid oxide fuel cells. Solid State Ion. 214, 1–5 (2012).

Fang, S. M., Yoo, C. Y. & Bouwmeester, H. J. M. Performance and stability of niobium-substituted Ba0.5Sr0.5Co0.8Fe0.2O3−δ membranes. Solid State Ion. 195, 1–6 (2011).

Ray, R. et al. Electronic structure of ordered double perovskite Ba2CoWO6 . AIP Conf. Proc. 1591, 1155–1157 (2014).

Ma, Z. & Zaera, F. Encyclopedia of Inorganic Chemistry (John Wiley, 2006).

de Bruijn, F. A., Dam, V. A. T. & Janssen, G. J. M. Durability and degradation issues of PEM fuel cell components. Fuel Cells 8, 3–22 (2008).

Shah, M., Voorhees, P. W. & Barnett, S. A. Time-dependent performance changes in LSCF- infiltrated SOFC cathodes: the role of nano-particle coarsening. Solid State Ion. 187, 64–67 (2011).

Jiang, S. P. Nanoscale and nano-structured electrodes of solid oxide fuel cells by infiltration: advances and challenges. Int. J. Hydrog. Energy 37, 449–470 (2012).

Tietz, F., Mai, A. & Stöver, D. From powder properties to fuel cell performance—a holistic approach for SOFC cathode development. Solid State Ion. 179, 1509–1515 (2008).

Haanappel, V. A. C. et al. Optimisation of processing and microstructural parameters of LSM cathodes to improve the electrochemical performance of anode-supported SOFCs. J. Power Sources 141, 216–226 (2005).

Coelho, A. A. TOPAS Academic: General Profile and Structure Analysis Software for Powder Diffraction Data (Bruker AXS, 2010).

Obst, M., Gasser, P., Mavrocordatos, D. & Dittrich, M. TEM-specimen preparation of cell/mineral interfaces by focused ion beam milling. Am. Mineral. 90, 1270–1277 (2005).

Leah, R. T. et al. Ceres power steel cell technology: rapid progress towards a truly commercially viable SOFC. ECS Trans. 68, 95–107 (2015).

Fergus, J. W. Electrolytes for solid oxide fuel cells. J. Power Sources 162, 30–40 (2006).

Johnson, D. ZView: A Software Program for IES Analysis Version 3.1c (Scribner Associates Inc., 2007).

Shin, F. et al. Self-assembled Dynamic Perovskite Composite Cathodes for Intermediate Temperature Solid Oxide Fuel Cells (Datacat, 2016); http://dx.doi.org/10.17638/datacat.liverpool.ac.uk/231

Acknowledgements

We thank EPSRC for support under EP/H000925 and EP/N004884. Synchrotron X-ray diffraction work was carried out with the support of Diamond Light Source (UK). Time-of-flight neutron diffraction work was carried out with the support of ISIS Spallation Source (UK). We thank C. Tang, S. Thompson, J. Parker and P. Adamson for assistance on Beamline I11 (Diamond Light Source) and R. Smith for assistance on POLARIS (ISIS). M.J.R. thanks the Royal Society for the award of a Research Professorship.

Author information

Authors and Affiliations

Contributions

M.J.R. and J.B.C. developed the concept for the study with input from J.F.S.; W.X. performed initial exploratory work with supervision from J.F.S.; J.F.S. designed and performed the remaining experiments, with the exceptions of DC conductivity measurement by S.N.S. and TEM work performed by K.D. and M.Z.; J.F.S. and M.J.R. wrote the first draft, which J.F.S. then expanded. All authors discussed the results and further developed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

A patent application covering this work has been filed by Ceres Intellectual Property Company Limited (UK patent application no. GB1421069.4, International patent application no. PCT/GB2015/053400) that names M.J.R., J.B.C., J.F.S. and W.X. as inventors.

Supplementary information

Supplementary Information

Supplementary Figures 1–18, Supplementary Tables 1–4, Supplementary Notes 1–8, Supplementary References. (PDF 1874 kb)

Rights and permissions

About this article

Cite this article

Shin, J., Xu, W., Zanella, M. et al. Self-assembled dynamic perovskite composite cathodes for intermediate temperature solid oxide fuel cells. Nat Energy 2, 16214 (2017). https://doi.org/10.1038/nenergy.2016.214

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/nenergy.2016.214

This article is cited by

-

Interfacial long-term effects of LSCF cathodes fired at different temperatures and tested at high current densities

Ionics (2023)

-

Gluing Ba0.5Sr0.5Co0.8Fe0.2O3−δ with Co3O4 as a cathode for proton-conducting solid oxide fuel cells

Science China Materials (2023)

-

Interfacial alloying between lead halide perovskite crystals and hybrid glasses

Nature Communications (2023)

-

Enhanced electrochemical performance of La0.6Sr0.4Co0.2Fe0.8O3−δ cathode via Ba-doping for intermediate-temperature solid oxide fuel cells

Nano Research (2022)

-

A high-entropy spinel ceramic oxide as the cathode for proton-conducting solid oxide fuel cells

Journal of Advanced Ceramics (2022)