Abstract

Several lignin samples of varying botanical nature (softwood, hardwood, or annual plants) and extraction procedures (Kraft, Organosolv, or soda) were fully characterized by complementary techniques and engaged in “catalyst-free” depolymerization in air under basic conditions. Treatment of the complex reaction mixture was optimized to ensure reproducibility, careful analyses, and accurate data. After an optimization of the reaction conditions, we were able to recover high amounts of aromatic compounds (up to 19%wt). Additionally, we demonstrated a relation between lignin’s structure, i.e., the accessible phenol moieties and inter-unit linkages, and the yields of aromatic compounds, thus showing the importance of the extraction process to optimize lignin’s potential. This work provides valuable reference for developing further lignin depolymerization under basic media.

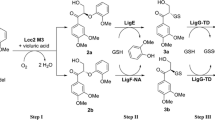

Graphical abstract

Similar content being viewed by others

References

Rinaldi R, Jastrzebski R, Clough MT, Ralph J, Kennema M, Bruijnincx PCA, Weckhuysen BM (2016) Paving the way for lignin valorisation: recent advances in bioengineering, biorefining and catalysis. Angew Chem Int Ed 55(29):8164–8215. https://doi.org/10.1002/anie.201510351

Zhang Z, Song J, Han B (2017) Catalytic transformation of lignocellulose into chemicals and fuel products in ionic liquids. Chem Rev 117(10):6834–6880. https://doi.org/10.1021/acs.chemrev.6b00457

Constant S, Wienk HLJ, Frissen AE, de Peinder P, Boelens R, van Es DS, Grisel RJH, Weckhuysen BM, Huijgen WJJ, Gosselink RJA, Bruijnincx PCA (2016) New insights into the structure and composition of technical lignins: a comparative characterisation study. Green Chem 18(9):2651–2665. https://doi.org/10.1039/C5GC03043A

Deuss PJ, Barta K (2016) From models to lignin: transition metal catalysis for selective bond cleavage reactions. Coord Chem Rev 306(Part 2):510–532. https://doi.org/10.1016/j.ccr.2015.02.004

de Menezes FF, Rencoret J, Nakanishi SC, Nascimento VM, Silva VFN, Gutiérrez A, del Río JC, de Moraes Rocha GJ (2017) Alkaline pretreatment severity leads to different lignin applications in sugar cane biorefineries. ACS Sus Chem Engineer 5(7):5702–5712. https://doi.org/10.1021/acssuschemeng.7b00265

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM (2010) The catalytic valorization of lignin for the production of renewable chemicals. Chem Rev 110(6):3552–3599. https://doi.org/10.1021/cr900354u

Galkin MV, Samec JSM (2016) Lignin valorization through catalytic lignocellulose fractionation: a fundamental platform for the future biorefinery. Chem Sus Chem 9(13):1544–1558. https://doi.org/10.1002/cssc.201600237

Gillet S, Aguedo M, Petitjean L, Morais ARC, da Costa Lopes AM, Lukasik RM, Anastas PT (2017) Lignin transformations for high value applications: towards targeted modifications using green chemistry. Green Chem 19(18):4200–4233. https://doi.org/10.1039/C7GC01479A

Sun Z, Fridrich B, de Santi A, Elangovan S, Barta K (2018) Bright side of lignin depolymerization: toward new platform chemicals. Chem Rev 118(2):614–678. https://doi.org/10.1021/acs.chemrev.7b00588

Zhang C, Wang F (2020) Catalytic lignin depolymerization to aromatic chemicals. Acc Chem Res 53(2):470–484. https://doi.org/10.1021/acs.accounts.9b00573

Bjørsvik H-R, Minisci F (1999) Fine chemicals from lignosulfonates. 1. Synthesis of vanillin by oxidation of lignosulfonates. Org Proc Res Develop 3(5):330–340. https://doi.org/10.1021/op9900028

Calvo-Flores FG, Dobado JA (2010) Lignin as renewable raw material. Chem Sus Chem 3(11):1227–1235. https://doi.org/10.1002/cssc.201000157

Roberts VM, Stein V, Reiner T, Lemonidou A, Li X, Lercher JA (2011) Towards quantitative catalytic lignin depolymerization. Chem Eur J 17(21):5939–5948. https://doi.org/10.1002/chem.201002438

Fache M, Boutevin B, Caillol S (2016) Vanillin production from lignin and its use as a renewable chemical. ACS Sus Chem Engineer 4(1):35–46. https://doi.org/10.1021/acssuschemeng.5b01344

Vidal J-P (2000) Vanillin. In: Kirk-Othmer encyclopedia of chemical technology. John Wiley & Sons, Inc. https://doi.org/10.1002/0471238961.2201140905191615.a01.pub2

Rødsrud G, Lersch M, Sjöde A (2012) History and future of world’s most advanced biorefinery in operation. Biomass Bioenergy 46(0):46-59. https://doi.org/10.1016/j.biombioe.2012.03.028

Rodrigues Pinto PC, Borges da Silva EA, Rodrigues AE (2012) Lignin as source of fine chemicals: vanillin and syringaldehyde. In: Baskar C, Baskar S, Dhillon RS (eds) Biomass conversion. Springer, Berlin Heidelberg, pp 381–420. https://doi.org/10.1007/978-3-642-28418-2_12

McClelland DJ, Galebach PH, Motagamwala AH, Wittrig AM, Karlen SD, Buchanan JS, Dumesic JA, Huber GW (2019) Supercritical methanol depolymerization and hydrodeoxygenation of lignin and biomass over reduced copper porous metal oxides. Green Chem 21(11):2988–3005. https://doi.org/10.1039/C9GC00589G

Maluenda I, Chen M-T, Guest D, Mark Roe S, Turner ML, Navarro O (2015) Room temperature, solventless telomerization of isoprene with alcohols using (N-heterocyclic carbene)–palladium catalysts. Cat Sci Tech 5(3):1447–1451. https://doi.org/10.1039/C5CY00058K

Cronin DJ, Zhang X, Bartley J, Doherty WOS (2017) Lignin depolymerization to dicarboxylic acids with sodium percarbonate. ACS Sus Chem Eng 5(7):6253–6260. https://doi.org/10.1021/acssuschemeng.7b01208

Danby AM, Lundin MD, Subramaniam B (2018) Valorization of grass lignins: swift and selective recovery of pendant aromatic groups with ozone. ACS Sus Chem Engineer 6(1):71–76. https://doi.org/10.1021/acssuschemeng.7b02978

Xu C, Arancon RAD, Labidi J, Luque R (2014) Lignin depolymerisation strategies: towards valuable chemicals and fuels. Chem Soc Rev 43(22):7485–7500. https://doi.org/10.1039/c4cs00235k

Schutyser W, Renders T, Van den Bosch S, Koelewijn SF, Beckham GT, Sels BF (2018) Chemicals from lignin: an interplay of lignocellulose fractionation, depolymerisation, and upgrading. Chem Soc Rev 47(3):852–908. https://doi.org/10.1039/C7CS00566K

Schutyser W, Kruger JS, Robinson AM, Katahira R, Brandner DG, Cleveland NS, Mittal A, Peterson DJ, Meilan R, Román-Leshkov Y, Beckham GT (2018) Revisiting alkaline aerobic lignin oxidation. Green Chem 20(16):3828–3844. https://doi.org/10.1039/C8GC00502H

Tarabanko VE, Fomova NA, Kuznetsov BN, Ivanchenko NM, Kudryashev AV (1995) On the mechanism of vanillin formation in the catalytic oxidation of lignin with oxygen. React Kinet Catal Lett 55(1):161–170. https://doi.org/10.1007/bf02075847

Tarabanko VE, Petukhov DV, Selyutin GE (2004) New mechanism for the catalytic oxidation of lignin to vanillin. Kinet Catal 45(4):569–577. https://doi.org/10.1023/B:KICA.0000038087.95130.a5

Argyropoulos DS (1995) 31P NMR in wood chemistry: a review of recent progress. Res Chem Intermed 21(3-5):373–395. https://doi.org/10.1007/bf03052265

Granata A, Argyropoulos DS (1995) 2-Chloro-4,4,5,5-tetramethyl-1,3,2-dioxaphospholane, a reagent for the accurate determination of the uncondensed and condensed phenolic moieties in lignins. J Agric Food Chem 43(6):1538–1544. https://doi.org/10.1021/jf00054a023

Popescu C-M, Popescu M-C, Singurel G, Vasile C, Argyropoulos DS, Willfor S (2007) Spectral characterization of eucalyptus wood. Appl Spectrosc 61(11):1168–1177

Bertaud F, Guillemain A, Tapin-Lingua S, Boiseau-Molina S, Petit-Conil M (2015) Softwood kraft lignin isolation from black liquor: from laboratory to pilot-scale production. Revue ATIP 69:6–9

Wildschut J, Smit AT, Reith JH, Huijgen WJJ (2013) Ethanol-based organosolv fractionation of wheat straw for the production of lignin and enzymatically digestible cellulose. Bioresour Technol 135:58–66. https://doi.org/10.1016/j.biortech.2012.10.050

Quesada-Medina J, López-Cremades FJ, Olivares-Carrillo P (2010) Organosolv extraction of lignin from hydrolyzed almond shells and application of the δ-value theory. Bioresour Technol 101(21):8252–8260. https://doi.org/10.1016/j.biortech.2010.06.011

Faix O (1991) Classification of lignins from different botanical origins by FT-IR spectroscopy. Holzforschung 45:21–28. https://doi.org/10.1515/hfsg.1991.45.s1.21

Faix O (1992) Fourier transform infrared spectroscopy. In: Lin S, Dence C (eds) Methods in lignin chemistry. Springer Series in Wood Science. Springer, Berlin Heidelberg, pp 233–241. https://doi.org/10.1007/978-3-642-74065-7_16

Vázquez G, Antorrena G, González J, Freire S (1997) FTIR, 1H and 13C NMR characterization of acetosolv-solubilized pine and eucalyptus lignins. Holzforschung 51(2):158–166. https://doi.org/10.1515/hfsg.1991.45.s1.21

Pandey KK (1999) A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J Appl Polym Sci 71(12):1969–1975. https://doi.org/10.1002/(sici)1097-4628(19990321)71:12<1969::aid-app6>3.0.co;2-d

Fodil Cherif M, Trache D, Brosse N, Benaliouche F, Tarchoun AF (2020) Comparison of the physicochemical properties and thermal stability of organosolv and Kraft lignins from hardwood and softwood biomass for their potential valorization. Wastes Biomass Valor. https://doi.org/10.1007/s12649-020-00955-0

John R, Larry LL (2010) NMR of Lignins. In: Lignin and Lignans. CRC Press, pp 137–243. https://doi.org/10.1201/EBK1574444865-c5

Wen J-L, Sun S-L, Xue B-L, Sun R-C (2013) Recent advances in characterization of lignin polymer by solution-state nuclear magnetic resonance (NMR) methodology. Materials 6(1):359–391

Sette M, Lange H, Crestini C (2013) Quantitative HSQC analyses of lignin: a practical comparison. Comput Struct Biotechnol J 6(7):1–7. https://doi.org/10.5936/csbj.201303016

Lundquist K (1992) Proton (1H) NMR spectroscopy. In: Lin S, Dence C (eds) Methods in lignin chemistry. Springer Series in Wood Science. Springer, Berlin Heidelberg, pp 242–249. https://doi.org/10.1007/978-3-642-74065-7_17

Delmas G-H, Benjelloun-Mlayah B, Bigot YL, Delmas M (2011) Functionality of wheat straw lignin extracted in organic acid media. J Appl Polym Sci 121(1):491–501. https://doi.org/10.1002/app.33592

El Hage R, Brosse N, Sannigrahi P, Ragauskas A (2010) Effects of process severity on the chemical structure of Miscanthus ethanol organosolv lignin. Polym Degrad Stab 95(6):997–1003. https://doi.org/10.1016/j.polymdegradstab.2010.03.012

Robert D (1992) Carbon-13 nuclear magnetic resonance spectrometry. In: Lin S, Dence C (eds) Methods in lignin chemistry. Springer Series in Wood Science. Springer, Berlin Heidelberg, pp 250–273. https://doi.org/10.1007/978-3-642-74065-7_18

Kanitskaya LV, Gogotov AF, Khai D, Rokhin AV (2012) Quantitative 13C NMR spectroscopy. Chemical structure of kraft and nitrosated lignins. Russ J Bioorg Chem 38(7):720–725. https://doi.org/10.1134/s1068162012070102

Jiang Z-H, Argyropoulos DS, Granata A (1995) Correlation analysis of 31P NMR chemical shifts with substituent effects of phenols. Magnet Res Chem 33(5):375–382. https://doi.org/10.1002/mrc.1260330509

Crestini C, Argyropoulos DS (1997) Structural analysis of wheat straw lignin by quantitative 31P and 2D NMR spectroscopy. The occurrence of ester bonds and α-O-4 substructures. J Agric Food Chem 45(4):1212–1219. https://doi.org/10.1021/jf960568k

Pu Y, Cao S, Ragauskas AJ (2011) Application of quantitative 31P NMR in biomass lignin and biofuel precursors characterization. Energy Environ Sci 4(9):3154–3166. https://doi.org/10.1039/c1ee01201k

Yuan T-Q, Sun S-N, Xu F, Sun R-C (2011) Characterization of lignin structures and lignin–carbohydrate complex (LCC) linkages by quantitative 13C and 2D HSQC NMR spectroscopy. J Agric Food Chem 59(19):10604–10614. https://doi.org/10.1021/jf2031549

del Río JC, Rencoret J, Prinsen P, Martínez ÁT, Ralph J, Gutiérrez A (2012) Structural characterization of wheat straw lignin as revealed by analytical pyrolysis, 2D-NMR, and reductive cleavage methods. J Agric Food Chem 60(23):5922–5935. https://doi.org/10.1021/jf301002n

Zeng J, Helms GL, Gao X, Chen S (2013) Quantification of wheat straw lignin structure by comprehensive NMR analysis. J Agric Food Chem 61(46):10848–10857. https://doi.org/10.1021/jf4030486

del Río JC, Rencoret J, Marques G, Li J, Gellerstedt G, Jiménez-Barbero J, Martínez ÁT, Gutiérrez A (2009) Structural characterization of the lignin from jute (Corchorus capsularis) fibers. J Agric Food Chem 57(21):10271–10281. https://doi.org/10.1021/jf900815x

Zhang A, Lu F, Sun R-C, Ralph J (2010) Isolation of cellulolytic enzyme lignin from wood preswollen/dissolved in dimethyl sulfoxide/N-methylimidazole. J Agric Food Chem 58(6):3446–3450. https://doi.org/10.1021/jf903998d

Sette M, Wechselberger R, Crestini C (2011) Elucidation of lignin structure by quantitative 2D NMR. Chem Eur J 17(34):9529–9535. https://doi.org/10.1002/chem.201003045

Huang X, Korányi TI, Boot MD, Hensen EJM (2014) Catalytic depolymerization of lignin in supercritical ethanol. Chem Sus Chem 7(8):2276–2288. https://doi.org/10.1002/cssc.201402094

Wen J-L, Sun S-L, Yuan T-Q, Xu F, Sun R-C (2013) Structural elucidation of lignin polymers of eucalyptus chips during organosolv pretreatment and extended delignification. J Agric Food Chem 61(46):11067–11075. https://doi.org/10.1021/jf403717q

You T-T, Mao J-Z, Yuan T-Q, Wen J-L, Xu F (2013) Structural elucidation of the lignins from stems and foliage of Arundo donax Linn. J Agric Food Chem 61(22):5361–5370. https://doi.org/10.1021/jf401277v

Hatfield R, Vermerris W (2001) Lignin formation in plants. The dilemma of linkage specificity. Plant Physiol 126(4):1351–1357. https://doi.org/10.1104/pp.126.4.1351

Delmas M (2008) Vegetal refining and agrochemistry. Chem Eng Technol 31(5):792–797. https://doi.org/10.1002/ceat.200800052

Wang Y, Sun S, Li F, Cao X, Sun R (2018) Production of vanillin from lignin: the relationship between β-O-4 linkages and vanillin yield. Ind Crop Prod 116:116–121. https://doi.org/10.1016/j.indcrop.2018.02.043

Wallick SA, Sarkanen KV (1983) Effect of pH on the autoxidation kinetics of vanillin. Wood Sci Technol 17(2):107–116. https://doi.org/10.1007/bf00369128

Vangeel T, Schutyser W, Renders T, Sels BF (2018) Perspective on lignin oxidation: advances, challenges, and future directions. Top Curr Chem 376(4):30. https://doi.org/10.1007/s41061-018-0207-2

Renders T, Van den Bosch S, Koelewijn SF, Schutyser W, Sels BF (2017) Lignin-first biomass fractionation: the advent of active stabilisation strategies. Energy Environ Sci 10(7):1551–1557. https://doi.org/10.1039/C7EE01298E

Deuss PJ, Scott M, Tran F, Westwood NJ, de Vries JG, Barta K (2015) Aromatic monomers by in situ conversion of reactive intermediates in the acid-catalyzed depolymerization of lignin. J Am Chem Soc 137(23):7456–7467. https://doi.org/10.1021/jacs.5b03693

Rahimi A, Ulbrich A, Coon JJ, Stahl SS (2014) Formic-acid-induced depolymerization of oxidized lignin to aromatics. Nature 515(7526):249–252. https://doi.org/10.1038/nature13867

Shuai L, Amiri MT, Questell-Santiago YM, Héroguel F, Li Y, Kim H, Meilan R, Chapple C, Ralph J, Luterbacher JS (2016) Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 354(6310):329–333. https://doi.org/10.1126/science.aaf7810

Acknowledgments

The authors thank C. Lorentz for her help with the NMR analyses. The authors thank AXELERA, cluster for the chemical and environmental sectors, for support.

Funding

The authors gratefully acknowledge the National Agency of Research (CHEMLIVAL No. ANR-12-CDII-0001_01) for funding. C. C. A. thanks the National Agency of Research (CHEMLIVAL No. ANR-12-CDII-0001_01) for grant. A. K. thanks GDRI (International Research Network) “Catalytic upgrading of Biomass” for grant.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

Characterization of lignins (1H NMR, 13C NMR, 31P NMR, and HSQC NMR spectra); General information for the depolymerization of lignins under oxidative conditions in the absence of catalyst and associated analytical data as HSQC NMR spectra. (DOCX 7584 kb).

Rights and permissions

About this article

Cite this article

Cabral Almada, C., Kazachenko, A., Fongarland, P. et al. Oxidative depolymerization of lignins for producing aromatics: variation of botanical origin and extraction methods. Biomass Conv. Bioref. 12, 3795–3808 (2022). https://doi.org/10.1007/s13399-020-00897-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00897-6