Abstract

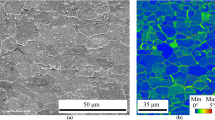

Changes in Young’s modulus E (determined according to ASTM E-111) of polycrystalline pure iron deformed by a tensile test at room temperature are determined. From its original mean value, 210 GPa, E decreased with deformation to a mean value of 196 GPa at ɛ=0.060. Thereafter, slight recovery occurred and E stabilized to 198 GPa until the appearance of neck (ɛ=0.100). With the aim to examine the causes of this behavior, residual stresses and textures were measured and the dislocation structure was observed by transmission electron microscopy (TEM). Longitudinal residual stresses increased from the first step of deformation (ɛ=0.015) and remained constant until the samples fractured. There was no significant difference in texture throughout the deformation process, during which the increment of α fiber was smooth. Thus, the decrease of E cannot be attributed to residual stresses or textures. A relationship between dislocation arrangement and decrease of E is proposed. Following the model established by Mott, dislocations can bow out in their glide planes, giving extra elastic strain and thus a decrease of E. The increase of the dislocation density during the first steps of deformation lowers the E values, since the extra elastic strain increases. At higher strains, when the cellular dislocation structure has formed (between ɛ=0.060 and 0.080), the dislocations in cell interiors are capable of giving an extra elastic strain, whereas the dislocations trapped in the cell walls are not. However, the dislocation density in cell interiors is lower than the dislocation density in the early stages of deformation in which the cell structure has not been developed. This produces the slight recovery of E measured at these strains. From ɛ=0.080, the values of E stabilized since no changes in dislocation density in cell interiors are observed.

Similar content being viewed by others

References

E. Papadakis: J. Testing Evaluation, 1998, vol. 26 (3), pp. 240–46.

K. Yamaguchi, H. Adachi, and N. Takakura: Met. and Mater., 1998, vol. 4, pp. 420–25.

F. Morestin and M. Boivin: Nucl. Eng. Design, 1996, vol. 162, pp. 107–16.

H.M. Ledbetter and S.A. Kim: Mater. Sci. Eng. A, 1988, vol. 101, pp. 87–92.

I. Fonseca, J.A. Benito, I. Mejía, J. Jorba, and A. Roca: Rev. Metall. Madrid, 2002, vol. 38 (4), pp. 249–55.

B.M. Drapkin, Y.P. Zamiatin, V.E. Vinogradov, and L.A. Zamiatina: Fiz. Khim. Obrab. Mater., 1988, vol. 4, pp. 127–31.

S. Shima and M. Yang: J. Soc. Mater. Sci. Jpn., 1995, vol. 44, pp. 578–83.

S.R. Agnew and J.R. Weertman: Mater. Sci. Eng. A, 1998, vol. 242, pp. 174–80.

W. Böcker, H.J. Bunge, and T. Reinert: Mater. Sci. Forum, 1994, vols. 157–162, pp. 1551–58.

Y.I. Ragozin, Y.Y. Antonov, and V.N. Anziferov: Proc. Euromat ’2000, Elsevier Science Ltd., New York, NY, 2000, vol. 1, pp. 419–24.

N.F. Mott: Phil. Mag., 1952, vol. 43, pp. 1151–178.

J. Friedel: Phil. Mag., 1953, vol. 44, pp. 444–48.

A.V. Granato and K. Lücke: J. Appl. Phys., 1956, vol. 27, p. 283.

G. Langford and M. Cohen: Trans. ASM, 1969, vol. 62, pp. 623–38.

Y. Lan, H.J. Klaar, and W. Dahl: Metall. Trans. A, 1992, vol. 23A, pp. 537–44.

P. Antoine, S. Vandeputte, and J.-B. Vogt, Iron Steel Inst. Jpn., 2005, vol. 45, pp. 399–404.

J.A. Benito, J. Jorba, and A. Roca: Mater. Sci. Forum, 2003, vols. 426–432, pp. 4435–40.

J. Jorba, R. Pons, J.A. Benito, and A. Roca: Special Issue: J. Mater. Processing Technol., 2001, vol. 117 (3), Thermec’00—Proc. Int. Conf. on Processing and Manufacturing Advanced Materials, Las Vegas, NV, CDROM.

I. Mejía: Ph.D. Thesis, University of Barcelona, Barcelona, 2002.

I.C. Noyan and J.E. Cohen: Residual Stresses Measurement by Diffraction and Interpretation, Springer-Verlag, New York, NY, 1987, pp. 117–25.

J.S. Kallend, U.F. Kocks, A.D. Rollett, and H.R. Wenk: Mater. Sci. Eng. A, 1991, vol. 132, pp. 1–11.

M.J. Cai and W.B. Lee: Mater. Sci. Forum, 1994, vols. 157–162, pp. 315–21.

M.T. Pérez-Prado, M.C. Cristina, O.A. Ruano, and G. González-Doncel: Mater. Sci. Eng. A, 1998, vol. 244, pp. 216–23.

R.K. Ham: Phil. Mag., 1961, vol. 6, pp. 1183–84.

V.D. Scott and G. Love: Mater. Sci. Technol., 1987, vol. 3, pp. 600–08.

T. Sawai and M. Suzuki: Scripta Mater., 1990, vol. 24, pp. 2047–52.

D.A. Korzekwa, D.K. Matlock, and G. Krauss: Metall. Trans. A, 1984, vol. 15A, pp. 1221–28.

Y. Estrin, L.S. Toth, A. Molinari, and Y. Brechet: Acta Mater, 1998, vol. 46, pp. 5509–22.

F.B. Prinz and A.S. Argon: Acta Mater, 1984, vol. 32, p. 1021.

X.F. Fang and W. Dahl: Mater. Sci. Eng. A, 1995, vol. 203, pp. 36–45.

Y. Lan, H.J. Klaar, and W. Dahl: Metall. Trans. A, 1992, vol. 23, pp. 545–49.

F. Petry and F. Pschenitzka: Mater. Sci. Eng., 1984, vol. 68, p. L7.

G.E. Dieter: Mechanical Metallurgy, McGraw-Hill, New York, NY, 1988, pp. 201–03.

M.A. Meyers and K.K. Chawla: Mechanical Metallurgy, Prentice-Hall, Elmsford, NJ, 1984, p. 398.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Benito, J.A., Jorba, J., Manero, J.M. et al. Change of Young’s modulus of cold-deformed pure iron in a tensile test. Metall Mater Trans A 36, 3317–3324 (2005). https://doi.org/10.1007/s11661-005-0006-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0006-6