Abstract

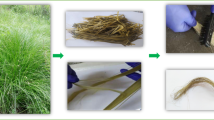

The açaí fruit industrial processing produces a large amount of waste, mainly seeds and fibers, which is a serious environmental and public health problem. The objective of this work was to use these fibers to obtain composites with natural rubber from different clones. The effect of the addition of açaí fibers and the type of clone were investigated using thermogravimetric analysis (TGA) under inert and oxidative atmospheres, differential scanning calorimetry (DSC), water sorption, and mechanical properties. The açaí fibers exhibited a thermal behavior comparable to other natural fibers industrially used in polymeric composites. The addition of the fibers did not influence the thermal stability of the composites. There was no significant effect of the type of clone and the addition of the fiber on the glass transition temperature, which was approximately −59 °C for all samples. Water sorption behavior of the compounds and of the composites was similar to that of the other materials with natural rubber that are reported in the literature. The promising performance of the composites with açaí fibers opens a new area of use for such fibers.

Similar content being viewed by others

References

Mokoena MA, Djokovic V, Luyt AS (2004) J Mater Sci 39(10):3403. doi:https://doi.org/10.1023/B:JMSC.0000026943.47803.0b

Mishra S, Mohanty AK, Drzal LT, Misra M, Hinrichsen G (2004) Macromol Mater Eng 289(11):955. doi:https://doi.org/10.1002/mame.200400132

Thwe MM, Liao K (2003) J Mater Sci 38(2):363. doi:https://doi.org/10.1023/A:1021130019435

Bledzki AK, Gassan J (1999) Prog Polym Sci 24(2):221. doi:https://doi.org/10.1016/S0079-6700(98)00018-5

Bisanda ETN, Ansell MP (1992) J Mater Sci 27(6):1690. doi:https://doi.org/10.1007/BF00542934

da Costa HM, Visconde LLY, Nunes RCR, Furtado CRG (2002) J Appl Polym Sci 83(11):2331. doi:https://doi.org/10.1002/app.10125

Varghese S, Kuriakose B, Thomas S, Kosh AT (1994) J Adhes Sci Technol 8(3):235. doi:https://doi.org/10.1163/156856194X01086

Murty VM, De SK (1982) J Appl Polym Sci 27(12):4611. doi:https://doi.org/10.1002/app.1982.070271208

Geethamma VG, Mathew KT, Lakshminarayanan R, Thomas S (1998) Polymer (Guildf) 39(6–7):1483. doi:https://doi.org/10.1016/S0032-3861(97)00422-9

Kumar RP, Geethakumari Amma ML, Thomas S (1995) J Appl Polym Sci 58(3):597. doi:https://doi.org/10.1002/app.1995.070580315

Gallori S, Bilia AR, Bergonzi MC, Barbosa WLR, Vincieri FF (2004) Chromatographia 59(11–12):739. doi:https://doi.org/10.1365/s10337-004-0305-x

Del Pozo-Insfran D, Brenes CH, Talcott ST (2004) J Agric Food Chem 52(6):1539. doi:https://doi.org/10.1021/jf035189n

Muñiz-Miret N, Vamos R, Hiraoka M, Montagnini F, Mendelsohn RO (1996) For Ecol Manage 87(1–3):163. doi:https://doi.org/10.1016/S0378-1127(96)03825-X

Pacheco-Palencia LA, Hawken P, Talcott ST (2007) Food Res Int 40(5):620. doi:https://doi.org/10.1016/j.foodres.2006.11.006

Pacheco-Palencia LA, Hawken P, Talcott ST (2007) Food Chem 105(1):28. doi:https://doi.org/10.1016/j.foodchem.2007.03.027

Schauss AG, Wu X, Prior RL, Ou B, Patel D, Huang D et al (2006) J Agric Food Chem 54(22):8598. doi:https://doi.org/10.1021/jf060976g

Coïsson JD, Travaglia F, Piana G, Capasso M, Arlorio M (2005) Food Res Int 38(8–9):893. doi:https://doi.org/10.1016/j.foodres.2005.03.009

Rodrigues RB, Lichtenthãler R, Zimmermann BF, Papagiannopoulos M, Fabricius H, Marx F (2006) J Agric Food Chem 54(12):4162. doi:https://doi.org/10.1021/jf058169p

Rogez H (2000) Açaí: Preparação, composição e melhoramento da conservação, 1st edn. EDUFPA, Brazil

Gonçalves PS, Silva MA, Gouvêa LRL, Scaloppi EJ, Scaloppi EJ Jr (2006) Sci Agric 63(3):246. doi:https://doi.org/10.1590/S0103-90162006000300006

Menon ARR, Pillai CKS, Nando GB (1996) Polym Degrad Stabil 52(3):265. doi:https://doi.org/10.1016/0141-3910(96)00007-9

Mwaikambo LY, Ansell MP (1999) Angew Makromolekulare Chem 272(1):108. doi :10.1002/(SICI)1522-9505(19991201)272:1<108::AID-APMC108>3.0.CO;2-9

Chand N, Sood S, Singh DK, Rohatgi PK (1987) J Therm Anal 32(2):595. doi:https://doi.org/10.1007/BF01912712

Martins MA, Joekes I (2003) J Appl Polym Sci 89(9):2507. doi:https://doi.org/10.1002/app.12285

Varma DS, Varma IK (1986) Thermochim Acta 108:199. doi:https://doi.org/10.1016/0040-6031(86)85092-4

Silva GG, de Souza DA, Machado JC, Hourston DJ (2000) J Appl Polym Sci 76(7):1197. doi :10.1002/(SICI)1097-4628(20000516)76:7<1197::AID-APP23>3.0.CO;2-G

Mwaikambo LY, Ansell MP (2002) J Appl Polym Sci 84(12):2222. doi:https://doi.org/10.1002/app.10460

Li SD, Yu HP, Peng Z, Zhu CS, Li PS (2000) J Appl Polym Sci 75(11):1339. doi :10.1002/(SICI)1097-4628(20000314)75:11<1339::AID-APP3>3.0.CO;2-0

de Medeiros ES, Moreno RMB, Ferreira FC, Alves N, Job AE, Gonçalves PS et al (2003) Prog Rubber Plast Recycl Technol 19(4):189

Sircar AK (1997) J Therm Anal 49(1):293. doi:https://doi.org/10.1007/BF01987450

Brazier DW (1980) Rubber Chem Technol 53(3):437

Sircar AK, Galaska ML, Rodrigues S, Chartoff RP (1999) Rubber Chem Technol 72(3):513

Sreekala MS, Kumaran MG, Thomas S (2002) Comp Part A Appl Sci Manuf 33(6):763. doi:https://doi.org/10.1016/S1359-835X(02)00032-5

Geethamma VG, Thomas S (2005) Polym Comp 26(2):136. doi:https://doi.org/10.1002/pc.20086

Acknowledgement

The authors thank FAPESP and CNPq for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martins, M.A., Pessoa, J.D.C., Gonçalves, P.S. et al. Thermal and mechanical properties of the açaí fiber/natural rubber composites. J Mater Sci 43, 6531–6538 (2008). https://doi.org/10.1007/s10853-008-2842-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2842-4