Abstract

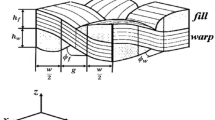

This study investigated the effect of two-dimensional fabric weaves (plain, twill, and satin) on the vibrational characteristics (natural frequency and damping) of woven carbon/epoxy composites. Natural frequencies of woven composites were measured by experimental modal analysis for plain weave, twill weave, and satin weave composites. The experimentally measured natural frequency results were compared with the ones predicted by numerical free vibration analysis. Numerical analysis was performed using a multiscale modelling approach. First, the impregnated fiber tow properties were predicted using periodic boundary conditions assuming that fibers are perfectly bonded. Then, the homogenized impregnated fiber tow properties and matrix properties were used to predict the natural frequencies of woven composite beams. The experimental and numerical results revealed that satin weave composites possess higher natural frequencies than plain weave composites. Flexural loss factor of woven composites was measured experimentally by dynamic mechanical analysis and half-power bandwidth method. Results from both analyses showed that plain weave composites have higher flexural loss factor as compared to satin weave composites.

Similar content being viewed by others

References

Abu Bakar IA, Kramer O, Bordas S, Rabczuk T (2013) Optimization of elastic properties and weaving patterns of woven composites. Compos Struct 100:575–591

Houshyar S, Shanks RA, Hodzic A (2005) Influence of different woven geometry in poly(propylene) woven composites. Macromol Mater Eng 290(1):45–52

Chretien N (2002) Numerical constitutive models of woven and braided textile structural composites. PhD diss., Virginia Polytechnic Institute and State University

Xu L, Wang R, Zhang S, Liu Y (2010) Vibration characteristics of glass fabric/epoxy composites with different woven structures. J Compos Mater 45(10):1069–1076

Rajesh M, Pitchaimani J (2015) Dynamic mechanical analysis and free vibration behavior of intra-ply woven natural fiber hybrid polymer composite. J Reinf Plast Compos 35(3):228–242

Pei X, Chen L, Gao Y, Li J, Tang Y (2017) Effect of reinforcement structures on vibration performance of composites. J Compos Mater. doi:10.1177/0021998316689602

Tita V, Carvalho JD, Lirani J (2001) A procedure to estimate the dynamic damped behavior of fiber reinforced composite beams submitted to flexural vibrations. Mater Res 4:315–321

Mishra I, Sahu SK (2014) Modal analysis of woven fiber composite plates with different boundary conditions. Int J Struct Stab Dyn 15(01):1540001

Guan H, Gibson RF (2001) Micromechanical models for damping in woven fabric-reinforced polymer matrix composites. J Compos Mater 35(16):1417–1434

Goertzen WK, Kessler MR (2007) Dynamic mechanical analysis of carbon/epoxy composites for structural pipeline repair. Compos B Eng 38(1):1–9

Liu X, Rouf K, Peng B, Yu W (2017) Two-step homogenization of textile composites using mechanics of structure genome. Compos Struct 171:252–262

Jansson S (1992) Homogenized nonlinear constitutive properties and local stress concentrations for composites with periodic internal structure. Int J Solids Struct 29(17):2181–2200

Rao MV, Mahajan P, Mittal RK (2008) Effect of architecture on mechanical properties of carbon/carbon composites. Compos Struct 83(2):131–142

Jeong H (1997) Effects of voids on the mechanical strength and ultrasonic attenuation of laminated composites. J Compos Mater 31(3):276–292

Blackketter DM, Upadhyaya D, King TR (1993) Micromechanics prediction of the transverse tensile strength of carbon fiber/epoxy composites: the influence of the matrix and interface. Polym Compos 14(5):437–446

Rouf K (2015) The effect of fabric weaves on the damping characteristics of woven fabric composites. MS Thesis, Purdue University

Lin H, Brown LP, Long AC (2011) Modelling and simulating textile structures using TexGen. Trans Tech Publ, Zürich, pp 44–47

Kirane K, Salviato M, Bažant ZP (2015) Microplane triad model for simple and accurate prediction of orthotropic elastic constants of woven fabric composites. J Compos Mater 50(9):1247–1260

Huang H, Talreja R (2005) Effects of void geometry on elastic properties of unidirectional fiber reinforced composites. Compos Sci Technol 65(13):1964–1981

Tremaine K (2012) Modal analysis of composite structures with damping material. California Polytechnic State University, San Luis Obispo

Acknowledgements

The authors would like to thank Hexcel Corporation for providing woven fabrics for this study, and Professor Ronald Sterkenburg and laboratory assistant Tyler Futch for their technical support during specimen manufacturing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rouf, K., Denton, N.L. & French, R.M. Effect of fabric weaves on the dynamic response of two-dimensional woven fabric composites. J Mater Sci 52, 10581–10591 (2017). https://doi.org/10.1007/s10853-017-1183-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1183-6