Abstract

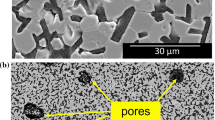

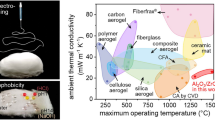

In this work, Y2O3-stabilized ZrO2 (YSZ) foams with low relative density were developed through the replication method, for application as porous radiant burners. The ceramic foams were produced by impregnation of open-cell polyurethane foams with aqueous suspensions and different fractions of raw materials: ZrO2–8% Y2O3 (8YSZ) powder, and additives. The materials were milled for 10–40 min. The impregnated foams were dried and submitted to a heat treatment for polyurethane elimination at 1000 °C for 1 h, with subsequent sintering of the remaining ceramic structure at 1600 °C for 2 h, which resulted in YSZ foams with low relative density (0.07). The structural analysis revealed a cellular structure with an average mechanical strength of 95.6 kPa. The radiation efficiency (>19%) was obtained by tests with different air/fuel ratio. The ceramic matrixes exhibited high performance and structural integrity at high operation temperatures (1400 °C).

Similar content being viewed by others

References

Jugjai S, Rungsimuntuchart N (2002) Exp Therm Fluid Sci 26:581

Scheffler M, Colombo P (2005) Cellular ceramics structure: manufacturing properties and applications. Wiley-VCH, Weinheim

Bone W (1913) J Franklin Inst 2:101

Lucke C (1913) J Ind Eng Chem 5:801

Trimis D, Wawrzinek K, Hatzfeld O, Lucka K, Rutsche A, Haase F, Krüger K, Küchen C (2001) In: Proceedings of the 6th international conference on technologies and combustion for a clear environment, Porto, p 717

Hayashi TC, Malico I, Pereira JCF (2004) Comput Struct 82:1543

Mößbauer S, Pickenäcker O, Pickernäcker K, Trimis D (1999) In: Proceedings of the 5th international conference on technologies and combustion for a clean environment, Lisbon, p 519

Schwartzwalder K, Somers AV (1963) US Patent 3 090 094, May

Sousa E, Rambo CR, Hotza DD, Oliveira APN, Fey T, Greil P (2007) Mater Sci Eng A. doi:https://doi.org/10.1016/j.msea.2007.05.098

Pereira F (2002) Medição de Características Térmicas e Estudo do Mecanismo de Estabilização de Chama em Queimadores Porosos Radiantes. Thesis (Master in Mechanical Engineering) UFSC, Brazil, 102 p

Gibson LJ, Asbhy MF (1997) Cellular solids: structure and properties. Cambridge University Press, London

Xinwen Z, Dongliang J, Shouhong T (2002) Mater Res Bull 37:541

Botella M (2005) Reología de Suspensiones Cerámicas. Consejo Superior de Investigaciones Científicas (CSIC), Madrid

Vedula VR, Green DJ, Hellman JR (1999) J Am Ceram Soc 82(3):649

Elverum PJ, Ellzey JL, Kovar D (2005) J Mater Sci 40:155. doi:https://doi.org/10.1007/s10853-005-5701-6

Khannan R, Goel R, Ellzey JL (1994) Combust Sci Technol 99:133

Pereira FM, Catapan RC, Oliveira AAM (2005) Development of a radiant porous burner with a combined thermal and fluidynamic mechanism of flame stabilization. In: 18th international congress of mechanical engineering, Ouro Preto, Brazil, 2005

Barra AJ, Ellzey JL (2004) Combust Flame 137:230

Orenstein RM, Green DJ (1992) J Am Ceram Soc 75(7):1899

Brezny R, Green DJ (1989) J Am Ceram Soc 72(7):1145

Acknowledgements

The authors are grateful to Capes and CNPq/Brazil for funding this work. The authors are equally grateful to labCET (UFSC) for their collaboration with the porous burner’s test.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gómez, S.Y., Escobar, J.A., Alvarez, O.A. et al. ZrO2 foams for porous radiant burners. J Mater Sci 44, 3466–3471 (2009). https://doi.org/10.1007/s10853-009-3462-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3462-3