Abstract

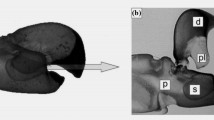

The snapping shrimp preys by rapidly closing its snapping claw to generate a fast water jet, creating a shockwave that bombards the nearby prey and other shrimp. This behaviour has led to considerable interest and research. However, the structure, surface morphology and mechanical properties of the snapping claw are unreported. We used a combination of techniques including scanning electron microscopy and nanoindentation to characterise the claw. These measurements were coupled with computational fluid dynamics (CFD) to understand how the microstructure contributes to drag reduction. We found that cone-shaped micropapillae, rhombic dents and short straight stripes were hierarchically distributed on the surface of the claw. CFD simulation showed that the micropapillae units changed the interaction between the turbulent and the wall from sliding friction to rolling friction, resulting in tire-shaped vortices. This also reduced the turbulent kinetic energy in the near-wall region, thereby contributing to drag reduction. The cross section of the claw revealed four layers comprising an epicuticle, exocuticle, endocuticle and a membranous layer. The exocuticle is composed of chitin fibres arranged vertically in a lamellar fashion and the endocuticle has a Bouligand-type structure. This special structure provides the snapping shrimp with good mechanical resistance during rapid closure. Both modulus and hardness decreased from the outermost epicuticle to the innermost membranous layer. The gradient modulus and hardness may help to suppress microcracks at the interfaces between different layers. The findings improve our understanding of the unique mechanism of the snapping claw and may lead to the development of novel biomimetic materials with enhanced drag reduction, impact and crack resistance properties.

Similar content being viewed by others

References

Versluis M, Schimitz B, Von der Heydt A, Lohse D (2000) How snapping shrimp snap: through cavitating bubbles. Science 289:2114–2117

Herberholz J, Schmitz B (1999) Flow visualization and high speed video analysis of water jets in the snapping shrimp (Alpheus heterochaelis). J Comp Physiol A 185:41–49

Schmiz B, Herberholz J (1998) Snapping movements and laser doppler anemometry analysis of water jets in the snapping shrimp Alpheus heterochaelis. In: Proceedings of the 26th Gottingen Neurobiol. Conf. 2: 241

Schmiz B, Herberholz J (1998) Snapping behavior in intraspecific agonistic encounters in the sanpping shirmp (Alpheus heterochaelis). J Biosci 23:623–632

Lohse D, Schmitz B, Versluis M (2001) Snapping shrimp make flashing bubbles. Nature 413:477–478

Ritzman RE (1974) Mechanisms for the snapping behavior of two Alpheid shrimp, Alpheus californiensis and Alpheus heterochelis. J Comp Physiol 95(3):217–236

Brown Kathryn (2000) For certain shrimp, life’s a snap. Science 289:2020–2021

Au WWL, Banks K (1998) The acoustics of the snapping shrimp Synalpheus parneomeris in Kaneohe Bay. J Acoust Soc Am 103:41–47

Epifanio CL, Potter JR, Deane GB, Readhead ML, Buckingham MJ (1999) Imaging in the ocean with ambient noise: the ORB experiments. J Acoust Soc Am 106(6):3211–3225

McNamara WB, Didenko YT, Suslick KS (1999) Sonoluminescence temperatures during multi-bubble cavitation. Nature 401:772–775

Schultz S, Wuppermann K, Schmitz B (1998) Behavioural interactions of snapping shrimp (Alpheus heterochaelis) with conspecifics and sympatric crabs (Eurypanopeus depressus). Zool Anal Complex Syst (Suppl I) 101:85

Kaji T, Anker A, Wirkner CS, Palmer AR (2018) Parallel saltational evolution of ultrafast movements in snapping shrimp claws. Curr Biol 28:1–8

Chen PY, Lin AY, McKittrick J, Meyers MA (2008) Structure and mechanical properties of crab exoskeletons. Acta Biomater 4:587–596

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19(1):3–20

Shu S, Lu J, Li D (2007) A systematic study of the validation of Oliver and Pharr’s method. J Mater Res 22(12):3385–3396

Koutsourakis N, Bartzis JG, Markatos NC (2012) Evaluation of Reynolds stress, k-ε, and RNG k-ε, turbulence models in street canyon flows using various experimental datasets. Environ Fluid Mech 12:379–403

Coirier WJ, Fricker DM, Furmanczyk M, Kim S (2005) A computational fluid dynamics approach for urban area transport and dispersion modeling. Environ Fluid Mech 5:443–479

Chan TL, Dong G, Leung CW, Cheung CS, Hung WT (2002) Validation of a two-dimensional pollutant dispersion model in an isolated street canyon. Atmos Environ 36:861–872

Girault V, Raviart PA (1986) Finite element methods for Navier-Stokes equations: theory and algorithms, vol 87. Springer, Berlin, pp 167–204

Martin S, Bhushan B (2016) Modeling and optimization of shark-inspired riblet geometries for low drag applications. J Colloid Interface Sci 474:206–215

Pu X, Li G, Liu Y (2016) Progress and perspective of studies on biomimetic shark skin drag reduction. ChemBioEng Rev 3:26–40

Chen HW, Zhang X, Ma LX, Che D, Zhang DY, Sudarshan TS (2014) Investigation on large-area fabrication of vivid shark skin with superior surface functions. Appl Surf Sci 316:124–131

Bixler GD, Bhushan B (2013) Fluid drag reduction with shark-skin riblet inspired microstructured surfaces. Adv Funct Mater 23:4507–4528

Dean B, Bhushan B (2010) Shark-skin surfaces for fluid-drag reduction in turbulentflow: a review. Philos Trans R Soc Lond A 368:4775–4806

Bixler GD, Bhushan B (2013) Shark skin inspired low-drag microstructured surfaces in closed channel flow. J Colloid Interface Sci 393:384–396

Afroz F, Lang A, Habegger ML, Motta P, Hueter R (2016) Experimental study of laminar and turbulent boundary layer separation control of shark skin. Bioinspir Biomim 12(1):016009

Afroz F, Sharif MA, Lang A (2016) Numerical study of adverse pressure gradient generation over a flat plate using a rotating cylinder. J Fluids Struct 62:187–208

Lang AW, Jones EM, Afroz F (2017) Separation control over a grooved surface inspired by dolphin skin. Bioinspir Biomim 12:026005

Liu E, Li L, Wang G, Zeng Z, Zhao W, Xue Q (2017) Drag reduction through self-texturing compliant bionic materials. Sci Rep 7:40038

Fish FE (2006) The myth and reality of Gray’s paradox: implication of dolphin drag reduction for technology. Bioinspir Biomim 1:R17–R25

Gad-el-Hak M (2002) Compliant coatings for drag reduction. Prog Aerosp Sci 38:77–99

Bandyopadhyay PR, Hellum AM (2014) Modeling how shark and dolphin skin patterns control transitional wall-turbulence vorticity patterns using spatiotemporal phase reset mechanisms. Sci Rep 4:6650

Weaver JC, Milliron GW, Miserez A, Evans-Lutterodt K, Herrera S, Gallana I, Mershon WJ, Swanson B, Zavattieri P, DiMasi E, Kisailus D (2012) The stomatopod dactyl club: a formidable damage-tolerant biological hammer. Science 336:1275–1280

Bouligand Y (1972) Twisted fibrous arrangements in biological materials and cholesteric mesophases. Tissue Cell 4:189–217

Weiner S, Addadi L (1997) Design strategies in mineralized biological materials. J Mater Chem 7:689–702

Yang RG, Zaheri A, Gao W, Hayashi C, Espinosa HD (2017) AFM identification of beetle exocuticle: bouligand structure and nanofiber anisotropic elastic properties. Adv Funct Mater 27:1603993

Yaraghi NA, Guarín-Zapata N, Grunenfelder LK, Hintsala E, Bhowmick S, Hiller JM, Betts M, Principe EL, Jung JY, Sheppard L, Wuhrer R, McKittrick J, Zavattieri PD, Kisailus D (2016) A sinusoidally architected helicoidal biocomposite. Adv Mater 28:6835–6844

Zimmermann EA, Gludovatz B, Schaible E, Dave NK, Yang W, Meyers MA, Ritchie RO (2013) Mechanical adaptability of the Bouligand-type structure in natural dermal armour. Nat Commun 4:2634

Chen PY, Lin AY, Lin YS, Seki Y, Stokes AG, Peyras J, Olevsky EA, Meyers MA, Mckittrick J (2008) Structure and mechanical properties of selected biological materials. J Mech Behav Biomed Mater 1:208–226

Lian J, Wang J (2014) Microstructure and mechanical anisotropy of crab cancer magister exoskeletons. Exp Mech 54:229–239

Raabe D, Sachs C, Romano P (2005) The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material. Acta Mater 53:4281–4292

Suresh S (2001) Graded materials for resistance to contact deformation and damage. Science 292(5526):2447–2451

Labonte D, Lenz AK, Oyen ML (2017) On the relationship between indentation hardness and modulus, and the damage resistance of biological materials. Acta Biomater 57(15):373–383

Yu W, Blanchard JP (1996) An elastic-plastic indentation model and its solutions. J Mater Res 11(09):2358–2367

Acknowledgements

This work was supported by grants from the National Natural Science Foundation of China (Nos. 51675222 & 51475202), the project on scientific and technological cooperation between China and Italy (No. 2016YFE0103700), the science and technology development planning project of Jilin Province (20180101068JC) and the program for JLU Science and Technology Innovative Research Team. RA is grateful to Jilin University for providing a travel scholarship (111 project) for research collaboration.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Qian, Z., Yang, M., Zhou, L. et al. Structure, mechanical properties and surface morphology of the snapping shrimp claw. J Mater Sci 53, 10666–10678 (2018). https://doi.org/10.1007/s10853-018-2364-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2364-7