Abstract

Effective elastic properties and residual stresses were assessed in directionally solidified ternary eutectic ceramic, Al2O3/YAG/ZrO2, by finite element analyses. A 3D finite element model was generated from a CT scan, representative of the microstructure and with a similar volume fraction. Effective elastic properties were calculated by numerical homogenisation. They highlight a quasi-isotropic behaviour of the ternary eutectic ceramics. Despite the difficulties to measure the strain, the dispersion observed in the results and the limited reliability of the materials properties, the results constitute a step towards a better understanding of the material behaviour. Thermal residual stresses induced by the manufacturing were also evaluated. Tensile residual stresses in yttria-stabilised zirconia and compressive residual stresses in YAG and alumina were highlighted. This evaluation also shed light on the influence of the phase morphology in the microstructure. Indeed, the computed spatial distribution of the residual stresses showed that they are different from one position to another due to the variation in phase morphology and also to material properties variability. Therefore, it is important when numerically assessing the thermomechanical properties to take into account the microstructure morphology as well as the variability of material properties.

Similar content being viewed by others

References

Orera VM, Llorca J (2005) Directionally solidified eutectic oxide ceramics in the encyclopedia of materials: science and technology. Elsevier, Amsterdam

Waku Y, Nakagawa N, Wakamoto T et al (1997) A ductile ceramic eutectic composite with high strength at 1,873 K. Nature 389:49–52

Waku Y, Nakagawa N, Wakamoto T et al (1998) High-temperature strength and thermal stability of a unidirectionally solidified Al2O3/YAG eutectic composite. J Mater Sci 33:1217–1225. doi:10.1023/A:1004377626345

Waku Y, Nakagawa N, Wakamoto T et al (1998) The creep and thermal stability characteristics of a unidirectionally solidified Al2O3/YAG eutectic composite. J Mater Sci 33:4943–4951. doi:10.1023/A:1004486303958

Nakagawa N, Ohtsubo H, Mitani A et al (2005) High temperature strength and thermal stability for melt growth composite. J Eur Ceram Soc 25:1251–1257

Yasuda H, Ohnaka I, Mizutani Y et al (2005) Three-dimensional observation of the entangled eutectic structure in the Al 2 O 3–YAG system. J Eur Ceram Soc 25:1397–1403

Waku Y, Sakata S-I, Mitani A, Shimizu K (2001) A novel oxide composite reinforced with a ductile phase for very high temperature structural materials. Mater Res Innov 5:94–100

Llorca J, Orera VM (2006) Directionally solidified eutectic ceramic oxides. Prog Mater Sci 51:711–809. doi:10.1016/j.pmatsci.2005.10.002

Mazerolles L, Perriere L, Lartigue-Korinek S, Parlier M (2011) Creep behavior and related structural defects in Al 2 O 3–Ln 2 O 3 (ZrO 2) directionally solidified eutectics (Ln= Gd, Er, Y). J Eur Ceram Soc 31:1219–1225

Waku Y, Sakuma T (2000) Dislocation mechanism of deformation and strength of Al 2 O 3–YAG single crystal composites at high temperatures above 1500 C. J Eur Ceram Soc 20:1453–1458

Palmero P, Pulci G, Marra F et al (2015) Al2O3/ZrO2/Y3Al5O12 composites: a high-temperature mechanical characterization. Materials 8:611–624

Sha JJ, Ochiai S, Okuda H et al (2008) Residual stresses in YAG phase in directionally solidified eutectic Al 2 O 3/YAG ceramic composite estimated by X-ray diffraction. J Eur Ceram Soc 28:2319–2324

Ramírez-Rico J, Martínez-Fernández J, Peña JI et al (2012) Residual stresses in Al 2 O 3–ZrO 2 (3 mol.% Y 2 O 3) directionally solidified eutectic ceramics as a function of temperature. Mater Sci Eng, A 541:61–66

Gouadec G, Colomban P, Piquet N et al (2005) Raman/Cr 3 + fluorescence mapping of a melt-grown Al 2 O 3/GdAlO 3 eutectic. J Eur Ceram Soc 25:1447–1453

Gouadec G, Makaoui K, Perrière L et al (2012) Ruby micro-piezospectroscopy in GdAlO 3/Al 2 O 3 (/ZrO 2), Er 3 Al 5 O 12/Al 2 O 3 (/ZrO 2) and Y 3 Al 5 O 12/Al 2 O 3 (/ZrO 2) binary and ternary directionally solidified eutectics. J Eur Ceram Soc 32:2145–2151

Orera VM, Cemborain R, Merino RI et al (2002) Piezo-spectroscopy at low temperatures: residual stresses in Al 2 O 3–ZrO 2 (Y 2 O 3) eutectics measured from 77 to 350 K. Acta Mater 50:4677–4686

Perrière L, Valle R, Carrère N et al (2011) Crack propagation and stress distribution in binary and ternary directionally solidified eutectic ceramics. J Eur Ceram Soc 31:1199–1210

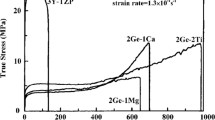

Valle R, Carroz L, Ritti M-H et al (2017) Mechanical testing of directionally solidified eutectic ceramics (DSECs): specific problems and limitations. J Mater Sci 52:10047–10061. doi:10.1007/s10853-017-1203-6

Ochiai S, Ikeda S, Iwamoto S et al (2008) Residual stresses in YAG phase of melt growth Al 2 O 3/YAG eutectic composite estimated by indentation fracture test and finite element analysis. J Eur Ceram Soc 28:2309–2317

Lakiza SM, Lopato LM (1997) Stable and metastable phase relations in the system alumina–zirconia–yttria. J Am Ceram Soc 80:893–902

Carroz L, Duffar T (2015) Working point of the EFG process. Cryst Res Technol 50:473–481

Londaitzbéhère L (2016) Etude de nouveaux composites eutectiques à base d’oxydes réfractaires préparés à partir de l’état fondu. Propriétés mécaniques et mécanismes de déformation à haute température. Stabilité de la microstructure en présence de vapeur d’eau. Ph.D. thesis, ICMPE

Cherif M (2016) Croissance de la céramique eutectique Al2O3-YAG-ZrO2:Y et étude de la microstructure Chinese Script. Ph.D. thesis, SIMaP-EPM, Grenoble

Avizo 9.0 (2015) 3D Analysis Software for Scientific and Industrial Data, FEI, France

Hazanov S, Huet C (1994) Order relationships for boundary conditions effect in heterogeneous bodies smaller than the representative volume. J Mech Phys Solids 42:1995–2011

Pahr DH, Zysset PK (2008) Influence of boundary conditions on computed apparent elastic properties of cancellous bone. Biomech Model Mechanobiol 7:463–476

Hovis DB, Reddy A, Heuer AH (2006) X-ray elastic constants for α-Al 2 O 3. Appl Phys Lett 88:131910

Z-set 8.6.5 (2016) Zébulon, Non-linear finite element solver, Transvalor - Centre des Matériaux, France

Bovet C, Parret-Fréaud A, Spillane N, Gosselet P (2017) Adaptive multipreconditioned FETI: scalability results and robustness assessment. Submitt Comput, Struct

Baste S, Hosten B (1990) Evaluation de la matrice d’élasticité des composites orthotropes par propagation ultrasonore en dehors des plans principaux de symétrie. Rev Phys Appliquée 25:161–168

Gourdin S, Marcin L, Podgorski M, et al (2017) Mechanical properties of ternary eutectic ceramic from room to very high temperature. In: 41st internationl conference on expo on advanced ceramic and composites

Perrière L (2008) Élaboration par solidification dirigée et comportement mécanique de céramiques eutectiques à base d’oxydes réfractaires: rôle de la microstructure sur la fissuration et la déformation plastique à haute température. PhD thesis, Paris Est

Alton WJ, Barlow AJ (1967) Temperature dependence of the elastic constants of yttrium aluminum garnet. J Appl Phys 38:3023–3024

Peña JI, Larsson M, Merino RI et al (2006) Processing, microstructure and mechanical properties of directionally-solidified Al 2 O 3–Y 3 Al 5 O 12–ZrO 2 ternary eutectics. J Eur Ceram Soc 26:3113–3121

Hillman C, Suo Z, Lange F (1996) Cracking of laminates subjected to biaxial tensile stresses. J Am Ceram Soc 79:2127–2133

Londaitzbéhère L, Lartigue-Korinek S, Mazerolles L (2017) Microstructure, interfaces and creep behaviour of Al2O3–Sm2O3 (ZrO2) eutectic ceramic composites. J Mater Sci 52:1–14. doi:10.1007/s10853-016-0726-6

Perrière L, Valle R, Mazerolles L, Parlier M (2008) Crack propagation in directionally solidified eutectic ceramics. In: Paper presentation second international workshop directiolal solidified eutectic ceram solidified eutectic ceram workshop II 28:2337–2343. doi:10.1016/j.jeurceramsoc.2008.01.005

Niederreiter H (1992) Random number generation and quasi-Monte Carlo methods. Society for Industrial and Applied Mathematics

McKay MD, Beckman RJ, Conover WJ (1979) Comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 21:239–245

Sobol IM (1993) Sensitivity estimates for nonlinear mathematical models. Math Model Comput Exp 1:407–414

Piquet N (2006) Microstructures interconnectées dans des eutectiques à base d’oxydes réfractaires élaborés par solidification dirigée. Ph.D. thesis, Paris-Est

Acknowledgements

The authors are grateful to the competitiveness cluster ‘MATERALIA’ and to the French MAT&PRO Program ‘CiNATRA’ ref: ANR-12-RMNP-0008 for financial support. The authors also thank P. Lhuissier from SIMaP-GPM2 for the CT scan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gourdin, S., Marcin, L., Podgorski, M. et al. Effective elastic properties and residual stresses in directionally solidified eutectic Al2O3/YAG/ZrO2 ceramics estimated by finite element analysis. J Mater Sci 52, 13736–13747 (2017). https://doi.org/10.1007/s10853-017-1479-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1479-6