Abstract

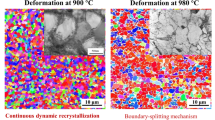

The effects of alpha/beta heat treatment on microstructure evolution of Ti-17 alloy with a lamellar colony structure are established. Heat treatment experiments are conducted at 1103 or 1063 K for times ranging from 10 min to 8 h. The main features of microstructure evolution during heat treatment comprise static globularization and coarsening of primary alpha phase. Such behaviors can be accelerated by higher heat treatment temperature. Furthermore, globularization and coarsening behaviors show a faster rate at higher prestrain. In order to better understand the microstructure evolution of Ti-17 alloy during alpha/beta heat treatment, static globularization and coarsening behaviors are modeled in the theoretical frame of the Johnson-Mehl-Avarmi-Kolmogorov (JMAK) and Lifshitz-Slyozov-Wagner (LSW) theories, respectively. The JMAK and LSW kinetics parameters are derived under different experimental conditions. Agreements between measurements and predictions are found, indicating that the JMAK and LSW theories can be used to predict and trace static globularization and coarsening processes of Ti-17 alloy during alpha/beta heat treatment.

Similar content being viewed by others

References

R.B. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng. A, 1996, 213, p 103–114

S. Fréour, D. Gloaguen, M. François, and R. Guillén, Application of Inverse Models and XRD Analysis to the Determination of Ti-17 β-Phase Coefficient of Thermal Expansion, Scripta Mater., 2006, 54, p 1475–1478

J.D.C. Teixeira, B. Appolaire, E. Aeby-Gautier, S. Denis, G. Cailletaud, and N. Späth, Transformation Kinetics and Microstructure of Ti17 Titanium Alloy During Continuous Cooling, Mater. Sci. Eng. A, 2007, 448, p 135–145

F. Bruneseaux, E. Aeby-Gautier, G. Geandier, J.D.C. Teixeira, B. Appolaire, P. Weisbecker, and A. Mauro, In Situ Characterizations of Phase Transformations Kinetics in the Ti17 Titanium Alloy by Electrical Resistivity and High Temperature Synchrotron X-ray Diffraction, Mater. Sci. Eng. A, 2008, 476, p 60–68

C.E. Shamblen, Minimizing Beta Flecks in the Ti-17 Alloy, Metall. Mater. Trans. B, 1997, 28, p 899–903

K.X. Wang, W.D. Zeng, Y.Q. Zhao, Y.J. Lai, and Y.G. Zhuo, Dynamic Globularization Kinetics During Hot Working of Ti-17 Alloy with Initial Lamellar Microstructure, Mater. Sci. Eng. A, 2010, 527, p 2559–2566

K.X. Wang, W.D. Zeng, Y.Q. Zhao, Y.T. Shao, and Y.G. Zhuo, Prediction of Dynamic Globularization of Ti-17 Titanium Alloy with Initial Lamellar Microstructure During Hot Compression, Mater. Sci. Eng. A, 2010, 527, p 6193–6199

X. Ma, W.D. Zeng, Y. Sun, K.X. Wang, Y.J. Lai, and Y.G. Zhuo, Modeling Constitutive Relationship of Ti17 Titanium Alloy with Lamellar Starting Microstructure, Mater. Sci. Eng. A, 2012, 538, p 182–189

S.L. Semiatin, S.L. Knisley, P.N. Fagin, F. Zhang, and D.R. Barker, Microstructure Evolution During alpha-Beta Heat Treatment of Ti-6Al-4V, Metall. Mater. Trans. A, 2003, 34, p 2377–2386

N. Stefansson, S.L. Semiatin, and D. Eylon, The Kinetics of Static Globularization of Ti-6Al-4V, Metall. Mater. Trans. A, 2002, 33, p 3527–3534

N. Stefansson and S.L. Semiatin, Mechanisms of Globularization of Ti-6Al-4V During Static Heat Treatment, Metall. Mater. Trans. A, 2003, 34, p 691–698

C.H. Park, J.W. Won, J.W. Park, S.L. Semiatin, and C.S. Lee, Mechanisms and Kinetics of Static spheRoidization of Hot-Worked Ti-6Al-2Sn-4Zr-2Mo-0.1Si with a Lamellar Microstructure, Metall. Mater. Trans. A, 2012, 43, p 977–985

X.G. Fan, H. Yang, S.L. Yan, P.F. Gao, and J.H. Zhou, Mechanism and Kinetics of Static Globularization in TA15 Titanium Alloy with Transformed Structure, J. Alloys Compd., 2012, 533, p 1–8

S.L. Semiatin, T.M. Lehner, J.D. Miller, R.D. Doherty, and D.U. Furrer, Alpha/Beta Heat Treatment of a Titanium Alloy with a Nonuniform Microstructure, Metall. Mater. Trans. A, 2007, 38, p 910–921

S. Zhu, H. Yang, L.G. Guo, and X.G. Fan, Effect of Cooling Rate on Microstructure Evolution During α/β Heat Treatment of TA15 Titanium Alloy, Mater. Charact., 2012, 70, p 101–110

S.L. Semiatin, B.C. Kirby, and G.A. Salishchev, Coarsening Behavior of an Alpha-Beta Titanium Alloy, Metall. Mater. Trans. A, 2004, 35, p 2809–2819

G. Grewal and S. Ankem, Particle Coarsening Behavior of α-β Titanium Alloys, Metall. Trans. A, 1990, 21, p 1645–1654

J.W. Xu, W.D. Zeng, Z.Q. Jia, X. Sun, and J.H. Zhou, Static Globularization Kinetics for Ti-17 Alloy With Initial Lamellar Microstructure, J. Alloys Compd., 2014, 603, p 239–247

K. Wang, W.D. Zeng, Y.T. Shao, Y.Q. Zhao, and Y.G. Zhou, Quantification of Microstructural Features in Titanium Alloys Based on Stereology, Rare Metal Mater. Eng., 2009, 38, p 398–403

X. Ma, W.D. Zeng, F. Tian, and Y.G. Zhou, The Kinetics of Dynamic Globularization During Hot Working of a Two Phase Titanium Alloy with Starting Lamellar Microstructure, Mater. Sci. Eng. A, 2012, 548, p 6–11

J.S. Kim, J.H. Kim, Y.T. Lee, C.G. Park, and C.S. Lee, Microstructural Analysis on Boundary Sliding and Its Accommodation Mode During Superplastic Deformation of Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 1999, 263, p 272–280

S.L. Semiatin, M.W. Corbett, P.N. Fang, G.A. Salishchev, and C.S. Lee, Dynamic-Coarsening Behavior of an α/β Titanium Alloy, Metall. Mater. Trans. A, 2006, 37, p 1125–1136

S.L. Semiatin, I.M. Sukonnik, and V. Seetharaman, An Analysis of Static Recrystallization During Continuous, Rapid Heat Treatment, Metall. Mater. Trans. A, 1996, 27, p 2051–2053

V. Erukhimovitch and J. Baram, Discussion of an Analysis of Static Recrystallization During Continuous, Rapid Heat Treatment, Metall. Mater. Trans. A, 1997, 28, p 2763–2764

Y.B. Chun, S.L. Semiatin, and S.K. Hwang, Monte Carlo Modeling of Microstructure Evolution During the Static Recrystallization of Cold-Rolled, Commercial-Purity Titanium, Acta Mater., 2006, 54, p 3673–3689

I.M. Lifshitz and V.V. Slyozov, The Kinetics of Precipitation from Supersaturated Solid Solutions, J. Phys. Chem. Solids, 1961, 19, p 35–50

C. Wagner, Theorie der alterung von niederschlägen durch umlösen, Z. Elektrochem., 1961, 65, p 581–591

A.J. Ardell, The Effect of Volume Fraction on Particle Coarsening: Theoretical Considerations, Acta Metall., 1972, 20, p 61–71

G. Grewal and S. Ankem, Isothermal Particle Growth in Two-Phase Titanium Alloys, Metall. Trans. A, 1989, 20, p 39–54

Y.L. Tian and R.W. Kraft, Kinetics of Pearlite Spheroidizations, Metall. Trans. A, 1987, 18, p 1403–1414

R. Racek and G. Lesoult, Ripening of Sn-Cd Eutectic Microstructures, J. Cryst. Growth, 1972, 16, p 223–226

Acknowledgments

The authors thank the financial supports from the Research Fund for the Doctoral Program of Higher Education of China (20136102110034) and the Program for New Century Excellent Talents in University (NCET-07-0696).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Zeng, W., Jia, Z. et al. Coarsening Kinetics and Morphological Evolution in a Two-Phase Titanium Alloy During Heat Treatment. J. of Materi Eng and Perform 25, 734–743 (2016). https://doi.org/10.1007/s11665-016-1951-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1951-5