Abstract

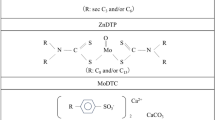

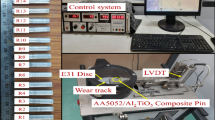

TiAl matrix composites incorporated with silver (Ag) and molybdenum disulfide (MoS2) are investigated to identify the improved friction and wear behavior over a wide temperature range. The results show that the excellent friction-reducing and anti-wear properties are obtained by the incorporation of Ag and MoS2, and the composite with 8 wt.% Ag and 4 wt.% MoS2 exhibits the lowest friction coefficients and wear rates under all testing temperatures. Such phenomenon is attributed to the adaptive-lubricating action of Ag and MoS2 as the temperature changes. Specifically, Ag and MoS2 are responsible for the improvements in friction and wear performance within 300 °C; MoS2, MoO3 and Ag2MoO4 are be beneficial to the decrease in friction coefficient and wear rate at 500 °C; Ag2MoO4 plays a supporting role in obtaining favorable frictional capability and good wear resistance at 700 °C.

Similar content being viewed by others

References

C. Rynio, H. Hattendorf, J. Klöwer, and G. Eggeler, The Evolution of Tribolayers During High Temperature Sliding Wear, Wear, 2014, 315, p 1–10

A. Pauschitza, M. Roy, and F. Franek, Mechanisms of Sliding Wear of Metals and Alloys at Elevated Temperatures, Tribol. Int., 2008, 41, p 584–602

W.B. Duan, Y.H. Sun, C.H. Liu, S.H. Liu, Y.Y. Li, C.H. Ding, G. Ran, and L. Yu, Study on the Formation Mechanism of the Glaze Film Formed on Ni/Ag Composites, Tribol. Int., 2016, 95, p 324–332

S.Y. Zhu, Q.L. Bi, M.Y. Niu, J. Yang, and W.M. Liu, Tribological Behavior of NiAl Matrix Composites with Addition of Oxides at High Temperatures, Wear, 2015, 274–275, p 423–434

A.J. Zhang, J.S. Han, B. Su, P.D. Li, and J.H. Meng, Microstructure, Mechanical Properties and Tribological Performance of CoCrFeNi High Entropy Alloy Matrix Self-lubricating Composite, Mater. Des., 2017, 114, p 253–263

J. Zollinger, J. Lapin, D. Daloz, and H. Combeau, Influence of Oxygen on Solidification Behaviour of Cast TiAl-Based Alloys, Intermetallics, 2007, 15, p 1343–1350

X.L. Shi, Z.S. Xu, M. Wang, W.Z. Zhai, J. Yao, and S.Y. Song, Tribological Behavior of TiAl Matrix Self-lubricating Composites Containing Silver from 25 to 800 °C, Wear, 2013, 303, p 486–494

S. Gupta and M.W. Barsoum, On the Tribology of the MAX Phases and Their Composites During Dry Sliding: A Review, Wear, 2011, 271, p 1878–1894

S.M. Aouadi, B. Luster, P. Kohli, C. Muratore, and A.A. Voevodin, Progress in the Development of Adaptive Nitride-Based Coatings for High Temperature Tribological Applications, Surf. Coat. Technol., 2009, 204, p 962–968

S. Mahathanabodee, T. Palathai, S. Raadnui, R. Tongsri, and N. Sombatsompop, Dry Sliding Wear Behavior of SS316L Composites Containing h-BN and MoS2 Solid Lubricants, Wear, 2014, 316, p 37–48

R. Tyagi, D.S. Xiong, J.L. Li, and J.H. Dai, Elevated Temperature Tribological Behavior of Ni Based Composites Containing Nano-silver and hBN, Wear, 2010, 269, p 884–890

J.L. Li, D.S. Xiong, and M.F. Huo, Friction and Wear Properties of Ni-Cr-W-Al-Ti-MoS2 at Elevated Temperatures and Self-consumption Phenomena, Wear, 2008, 265, p 566–575

S.M. Aouadi, Y. Paudel, B. Luster, S. Stadler, P. Kohli, C. Muratore, C. Hager, and A.A. Voevodin, Adaptive Mo2N/MoS2/Ag Tribological Nanocomposite Coatings for Aerospace Applications, Tribol. Lett., 2008, 29, p 95–103

C. Muratore and A. Voevodin, Molybdenum Disulfide as a Lubricant and Catalyst in Adaptive Nanocomposite Coatings, Surf. Coat. Technol., 2006, 201, p 25–30

W.Z. Zhai, X.L. Shi, Z.S. Xu, and A. Zhang, Investigation of the Friction Layer of Ni3Al Matrix Composites, Wear, 2015, 328–329, p 39–49

Z.S. Xu, Q.X. Zhang, P.X. Jing, and W.Z. Zhai, High Temperature Tribological Performance of TiAl Matrix Composites Reinforced by Multilayer Graphene, Tribol. Lett., 2015, 58, p 3

J.J. Hu, C. Muratore, and A.A. Voevodin, Silver Diffusion and High-Temperature Lubrication Mechanisms of YSZ-Ag-Mo Based Nanocomposite Coatings, Surf. Coat. Technol., 2007, 67, p 336–347

Z.S. Xu, X.L. Shi, W.Z. Zhai, J. Yao, S.Y. Song, and Q.X. Zhang, Preparation and Tribological Properties of TiAl Matrix Composites Reinforced by Multilayer Graphene, Carbon, 2014, 67, p 168–177

B. Xue, P.X. Jing, and W.D. Ma, Tribological Properties of NiAl Matrix Composites Filled with Serpentine powders, J. Mater. Eng. Perform., 2017, 26, p 5816–5824

E.Y. Liu, W.Z. Wang, Y.M. Gao, and J.H. Jia, Tribological Properties of Ni-Based Self-lubricating Composites with Addition of Silver and Molybdenum Disulfide, Tribol. Int., 2013, 57, p 235–241

Z.S. Xu, Q.X. Zhang, and W.Z. Zhai, Tribological Properties of TiAl Matrix Self-lubricating Composites Incorporated with Tungsten Disulfide and Zinc Oxide, RSC Adv., 2015, 5, p 45044–45052

J.L. Li and D.S. Xiong, Tribological Behavior of Graphite-Containing Nickel-Based Composite as Function of Temperature, Load and Counterface, Wear, 2009, 266, p 360–367

J.L. Li, D.S. Xiong, H.Y. Wu, J.H. Dai, and T. Cui, Tribological Properties of Molybdenized Silver-Containing Nickel Base Alloy at Elevated Temperatures, Tribol. Int., 2009, 42, p 1722–1729

K. Rajkumar and S. Aravindan, Tribological Studies on Microwave Sintered Copper-Carbon Nanotube Composites, Wear, 2011, 270, p 613–621

Y.K. Qin, D.S. Xiong, J.L. Li, Q.T. Jin, Y. He, R.C. Zhang, and Y.R. Zou, Adaptive-Lubricating PEO/Ag/MoS2 Multilayered Coatings for Ti6Al4V Alloy at Elevated Temperature, Mater. Des., 2016, 107, p 311–321

G.T. Li, H.M. Qi, G. Zhang, F.Y. Zhao, T.M. Wang, and Q.H. Wang, Significant Friction and Wear Reduction by Assembling Two Individual PEEK Composites with Specific Functionalities, Mater. Des., 2017, 116, p 152–159

Y.H. Wang, J.H. Ouyang, Z.G. Liu, Y.M. Wang, and Y.J. Wang, Microstructure and High Temperature Properties of Two-Step Voltage-Controlled MAO Ceramic Coatings Formed on Ti2AlNb Alloy, Appl. Surf. Sci., 2014, 307, p 62–68

Y.K. Qin, D.S. Xiong, and J.L. Li, Tribological Properties of Laser Surface Textured and Plasma Electrolytic Oxidation Duplex-Treated Ti6Al4V Alloy Deposited with MoS2 Film, Surf. Coat. Technol., 2015, 259, p 266–272

J. Chen, X.Q. Zhao, H.D. Zhou, J.M. Chen, Y.L. An, and F.Y. Yan, Microstructure and Tribological Property of HVOF-Sprayed Adaptive NiMoAl-Cr3C2-Ag Composite Coating from 20 to 800 °C, Surf. Coat. Technol., 2014, 258, p 1183–1190

J. Cheng, J. Yang, X.H. Zhang, H. Zhong, J.Q. Ma, F. Li, L.C. Fu, Q.L. Bi, J.S. Li, and W.M. Liu, High Temperature Tribological Behavior of a Ti-46Al-2Cr-2Nb Intermetallics, Intermetallics, 2012, 31, p 120–126

Y. Wu, F. Wang, Y. Cheng, and N. Chen, A Study of the Optimization Mechanism of Solid Lubricant Concentration in Ni/MoS2 Self-lubricating Composite, Wear, 1997, 205, p 64–70

D.V. Shtansky, A.V. Bondarev, P.V. Kiryukhantsev-Korneev, T.C. Rojas, V. Godinho, and A. Fernández, Structure and Tribological Properties of MoCN-Ag Coatings in the Temperature Range of 25–700 °C, Appl. Surf. Sci., 2013, 273, p 408–414

S.A. Alidokht, A. Abdollah-zadeh, and H. Assadi, Effect of Applied Load on the Dry Sliding Wear Behaviour and the Subsurface Deformation on Hybrid Metal Matrix Composite, Wear, 2013, 305, p 291–298

T.T. Zhang, C.B. Huang, H. Lan, L.Z. Du, and W.G. Zhang, Tribological Properties and Lubrication Mechanisms of a Ag-Mo Composite, Lubr. Sci., 2016, 28, p 141–156

Z.S. Xu, X.L. Shi, Q.X. Zhang, W.Z. Zhai, X.X. Li, J. Yao, S.Y. Song, L. Cheng, Y.C. Xiao, and Q.S. Zhu, Wear and Friction of TiAl Matrix Self-lubricating Composites Against Si3N4 in Air at Room and Elevated Temperatures, Tribol. T., 2014, 57, p 1017–1027

E.Y. Liu, Y.M. Gao, J.H. Jia, and Y.P. Bai, Friction and Wear Behaviors of Ni-Based Composites Containing graphite/Ag2MoO4 Lubricants, Tribol. Lett., 2013, 50, p 313–322

Acknowledgments

This work was supported by the Project for Science and Technology Plan of Yellow River Conservancy Technical Institute [grant number 2017KXJS005] and the Excellent-Young-Backbone Teacher Project in high school of Henan Province [grant number 2017GGJS-223].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, B., Ma, W. & Liu, Y. Friction and Wear Behavior of TiAl Matrix Composites Incorporated with Silver and Molybdenum Disulfide. J. of Materi Eng and Perform 27, 4176–4182 (2018). https://doi.org/10.1007/s11665-018-3533-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3533-1