Abstract

Fastened pre-tensioning is conducted on sheet metal prior to incremental forming, thus causing pre-plastic deformation of the sheet metal. To accomplish this process, a 1060H24 aluminum sheet is selected as material, a prosthesis with typical external features as object, and the NHSK1060 incremental sheet forming machine as experimental equipment. By analyzing the forming parts and comparing with conventional incremental sheet forming techniques, fastened pre-tensioning can efficiently improve the springback of incremental forming. Influenced by frictional stress τr, the strain gradually augments with distance from the center. The strain reaches maximum levels around the annular region, which is the pre-tensioning contact area edge of the sheet metal and the support body. The thickness distribution of sheet metal follows cosine law, with fastened pre-tensioning influencing its thickness.

Similar content being viewed by others

References

Matsubara S (1994) Incremental backward bulge forming of a sheet metal with a hemispherical head tool. J JSTP 35:1311–1316

Matsubara S (2001) Computer numerically controlled dieless incremental forming of a sheet metal. Proc Inst Mech Eng B J Eng Manuf 215:959–966

Hussain G, Gao L, Hayat N, Dar NU (2010) The formability of annealed and pre-aged AA-2024 sheets in single-point incremental forming. Int J Adv Manuf Technol 46:543–549

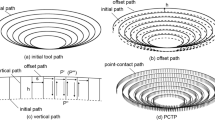

Jie L, Jianhua M, Shuhuai H (2004) Sheet metal dieless forming and its tool path generation based on STL files. Int J Adv Manuf Technol 23:696–699

Jong JP, Yung HK (2003) Fundamental studies on the incremental sheet metal forming technique. J Mater Process Technol 140(1–3):447–453

Chin KS (1998) Implementation of rapid prototyping technology—a Hongkong manufacturing industry’s perspective. Int J Adv Manuf Technol 14:570–579

Bambach M (2010) A geometrical model of the kinematics of incremental sheet forming for the prediction of membrane strains and sheet thickness. J Mater Process Technol 21(12):1562–1573

Hussain G, Gao L (2007) A novel method to test the thinning limits of sheet metals in negative incremental forming. Int J Mach Tools Manuf 47(3–4):419–425

Hill R (1950) Mathematical theory of plasticity [M]. Clarendon, Oxford

Yamashita M, Gotoh M, Atsumi SY (2008) Numerical simulation of incremental forming of sheet metal. J Mater Proc Technol 199:163–172

Iseki H (2001) An approximate deformation analysis and FEM analysis for the incremental bulging of sheet metal using a spherical roller. J Mater Process Technol 111:150–154

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zha, G.C., Shi, X.F., Zhao, W. et al. Experimental research of incremental sheet forming based on fastened pre-tensioning. Int J Adv Manuf Technol 82, 711–717 (2016). https://doi.org/10.1007/s00170-015-7411-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7411-9