Abstract

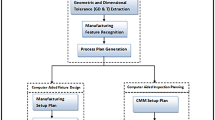

A method is described for the automatic design of assemblies of modular fixturing elements. Its input is a description of the workpiece geometry, the machining envelope, and the position and types of location, clamping, and support elements. Its output is an automatically generated fixture design. The program incorporates systematic design procedure in conjunction with a large library of rules governing the movement and combination of the modular elements. A key feature of the system is the development of a new spatial representation technique. This technique permits the program to search and identify both objects and object intersections. It is also able to determine the position of objects during the design process. A design example is given to illustrate the method.

Similar content being viewed by others

References

D. F. Eary and G. E. Johnson,Process Engineering for Manufacturing, Prentice-Hall, New Jersey, 1962.

D. J. Williams,Manufacturing Systems, Halsted Press, New York, Toronto, and Open University Press, Milton Keynes, 1987.

K. Whybrew, G. A. Britton, D. F. Robinson and A. Y. Sermsuti-Anuwat, “A graph-theoretic approach to tolerance charting”,The International Journal of Advanced Manufacturing Technology,5 (2) pp. 175–183, 1990.

A. Y. C. Nee, N. Bhattacharyya and A. N. Poo, “Applying Al in jig and fixture design”,Robotics and Computer-Intergrated Manufacturing,3(2), pp. 195–200, 1987.

D. T. Pham, M. J. Nategh and A. de Sam Lazaro, “A knowledgebased jig and fixture designers' assistant”,The International Journal of Advanced Manufacturing Technology,4(1), pp. 26–45, 1989.

A. Farkus, Z. Markusz, J. Farkas and J. Filemon, “Fixture design using Prolog: an expert system’,Robotic and Computer Integrated Manufacturing,1(2), pp. 167–172, 1984.

H. Asada and A. B. By, “Kinematic analysis of workpiece fixturing for flexible assembly with automatically reconfigurable fixtures”,TEEE Journal of Robotics and Automation,RA 1(2), pp. 86–94, 1985.

J. R. Woodward and D. Graham, “Automated assembly and inspection of versatile fixtures”,Second International Conference on Flexible Manufacturing Systems, IFS (Conferences), London, pp. 425–430, October 1983.

K. Whybrew, R. J. Astley and B. K. A. Ngoi, “Computer aided assembly of modular fixturing systems”,International Conference on Industrial Engineering, Singapore, September 1988.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Whybrew, K., Ngoi, B.K.A. Computer aided design of modular fixture assembly. Int J Adv Manuf Technol 7, 267–276 (1992). https://doi.org/10.1007/BF02682441

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02682441