Abstract

Electrically conductive materials are rapidly heated to temperatures near 7000° F in the newly developed facility described in this paper. The facility was designed to be used in conjunction with a high-strain-rate machine for testing a variety of materials including graphites, carbon phenolic and many metals under uniaxial stress states. A description of the direct resistance (I 2R) heating technique is given, including discussion on the design problems and considerations associated with heating materials to very high temperatures. Among these considerations are measurement of true temperature, measurement of load and strain, reduction of radiative losse from the sample surface, protection of the gripping contact and alignment of the specimen for uniaxia-stress high-strain-rate testing. Heating rates approaching 20,000° F/sec have been realized and some preliminary test results are shown.

Similar content being viewed by others

References

Katsikas, C. J., Castle, G. K., and Higgins, J. S., “ablation Handbook Entry Materials Data and Design,” Air Force Materials Laboratory Report, AFML-TR-66-262, (AD 809-446) (Nov. 1966).

Wilson, R. B., “Thermophysical Properties of Six Charring Ablators from 140° to 700° K and Two Chars from 800° to 3000° K,” NASA Technical Note TN D-2991 (Oct. 1965).

Chapman, A. J., “An Experimental Evalution of Three Types of Thermal Protection Materials at Moderate Heating Rates and High Total Heat Loads,” NASA Technical Note TN D-1814 (July 1963).

Welsh, W. E., Jr. andChing, A., “A New Technique for Mechanical Strength Testing of Rapidly Charred Ablation Materials,”AIAA Jnl.,5 (10),1882 (1967).

Hoglund, R. F., Babcock, S. G., and Groves, R. N., Jr., “Ablation Test Specimen Environment at High Temperature,” AIAA /ASME 10th Structure, Structural Dynamics and Materials Conference (April 14–16, 1969).

Babcock, S. G., and Perkins, R. D., “High Strain-Rate Response of Three Heat-Shjield Materials at Elevated Temperatures,” Volume II of Material Response Study (MARS) Final Report, Air Force Contract AF04694-67-C-0033, SAMSO TR-68-71 (Jan. 1968).

Landers, L. L., Jr., Atkinson, J., and Theberge, C. C., “Effects of Time at Temperature on the Mechanical Properties of a Fabric Reinforced Phenolic Heat Shield Material,” AIAA/ASME 10th Structures, Structural Dynamics and Materials Conference (April 14–16, 1969).

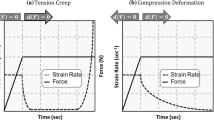

Maiden C. J. and Green, S. J., “Compression Strain Rate Tests on Six Selected Materials at Strain Rates from 10 −3 to 104 in/in/sec,” Jnl. Appl. Mech.,33 (Sept. 1966).

Jamieson, J. A., et al., Infrared Physics and Engineering, McGraw-Hill (1963).

D'Amelio V. J. and Roetling, J. A., “Extreme Temperature Performance of Graphites,” presented at AICHE Materials Conference, Philadelphia, Pa. (March 31–April 4, 1968).

Reentry Materials Handbook, prepared by Aerospace Corporation for U. S. Air Force, Report No. TOR-1001 (S2855-20)-3, (Conf.) (April 1968).

Author information

Authors and Affiliations

Additional information

Work was sponsored by Space and Missile Systems Organization, Air Force Systems Command, Contraxct F04701-68-C-0161, monitored by Major N. J. Azzarita.

Rights and permissions

About this article

Cite this article

Babcock, S.G., Hochstein, P.A. High-strain-rate testing of rapidly heated conductive materials to 7000° F. Experimental Mechanics 10, 78–83 (1970). https://doi.org/10.1007/BF02320136

Issue Date:

DOI: https://doi.org/10.1007/BF02320136