Abstract

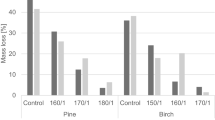

Copper-ethanolamine based wood preservatives are the most important products for protection of wood in use class III and IV applications. These preservatives can be applied using different procedures. One of them is dipping, a method which is predominantly used in less industrialised countries. The most important parameter, that influences the quality of this treatment, is dipping time. Influence of various dipping times on copper retention, adsorption, penetration, colour of the specimens and copper fixation was examined. In this paper copper-ethanolamine solutions of two different concentrations were utilised (cCu=0.05% or 0.25%). The results showed that longer dipping treatments resulted in higher uptakes of preservative solution, better penetrations and lower leaching of copper-ethanolamine based wood preservatives from Norway spruce wood. After one week of dipping, samples retained on average 275 kg/m3 of preservative solution, copper active ingredients penetrated on average 3 mm into the specimens, and only 2.3% of copper was emitted from wood impregnated with aqueous solution of the higher concentration, when subjected to ENV 1250 leaching procedure.

Zusammenfassung

Kupferethanolamin basierte Holzschutzmittel sind die wichtigsten Produkte zum Schutz von Holz in den Gebrauchsklassen III und IV. Diese Schutzmittel können mit unterschiedlichen Verfahren eingebracht werden, wie zum Beispiel dem Tauchverfahren, das überwiegend in weniger industrialisierten Ländern angewandt wird. Der wichtigste Parameter für die Imprägnierqualität ist die Eintauchdauer. Untersucht wurde der Einfluss unterschiedlicher Eintauchzeiten auf die Kupferaufnahme, die Adsorption, die Eindringung und die Farbe der Proben sowie die Kupferfixierung. In dieser Studie wurden zwei unterschiedliche Konzentrationen von Kupferethanolaminlösungen (cCu=0.05% oder 0.25%) verwendet. Die Ergebnisse zeigten, dass bei Fichtenholz eine längere Eintauchdauer eine höhere Aufnahme der Schutzmittellösung, bessere Eindringung und geringere Auswaschung von Kupferethanolamin basierten Holzschutzmitteln ergab. Nach einer einwöchigen Eintauchzeit wurden durchschnittlich 275 kg/m3 Holzschutzmittel aufgenommen, Kupferwirkstoffe drangen durchschnittlich 3 mm tief in das Holz ein und nur 2.3% Kupfer wurden bei einem Versuch nach ENV 1250 aus dem mit einer wässrigen Lösung der höheren Konzentration imprägnierten Holz ausgewaschen.

Similar content being viewed by others

References

Baillères H, Grenier D, Méot JM, Langbour P, Blanchard C, Lanvin JD (2004) Innovative multi-functional wood treatment process based on bi-oleothermy. COST E22, Estoril, Portugal, 32

Biocidal Products Directive 98/8/EC (1998) Official Journal of the European Communities 1998, L123:1–63

Brock T, Groteklaes M, Mischke P (2000) European Coatings Handbook. Vincentz Verlag, Hannover, p 410

Cao J, Yu L (2007) Copper fixation in ACQ-D treated Chinese fir at various temperature and relative humidity conditions. The International Research Group for Wood Protection IRG/WP 07-30436, 13

Cao JZ, Kamdem DP (2004) Microwave treatment to accelerate fixation of copper ethanolamine (Cu-EA) treated wood. Holzforschung 58:569–571

ENV 1250-2 European Committee for Standardization (1994) Wood preservatives – Methods for measuring losses of active ingredients and other preservative ingredients from treated timber – Part 2: Laboratory method for obtaining samples for analysis to measure losses by leaching into water or synthetic sea water, Brussels, 16

Hingston JA, Moore J, Bacon A, Lester JN, Murphy RJ, Collins CD (2002) The importance of the short-term leaching dynamics of wood preservatives. Chemosphere 47:517–523

Humar M, Kalan P, Pohleven F, Šentjurc M (2005) Influence of carboxylic acids on fixation of copper in wood impregnated with copper amine based preservatives. Wood Sci Technol 39:685–693

Humar M, Pohleven F (2006) Solution for wood preservation: no. WO 2006/031207 A1. Geneva: World intellectual property organization, 16

Humar M, Žlindra D, Pohleven F (2007) Fixation of copper-ethanolamine wood preservatives to Norway spruce sawdust. Acta Chim Slov 54:154–159

Kamdem DP, Freeman MH, Woods TL (1996) Bioefficacy of Cunapsoltreated western cedar and southern yellow pine. The International Research Group for Wood Protection. IRG/WP 96-30120, 13

Richardson BA (1993) Wood Preservation. 2nd edn, E & FN Spon, London, p 226

Solo-Gabriele H, Townsend T (2006) Environmental Impacts of Preservative-Treated Wood. Taylor & Francis Group, Boca Raton, p. 501

Temiz A, Yildiz UC, Nilsson T (2006) Comparison of copper emission rates from wood treated with different preservatives to the environment. Build Environ 41:910–914

Zhang J, Kamdem DP (2000) Interactions of copper-amine with southern pine: retention and Migration. Wood Fiber Sci 32:332–339

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Humar, M., Lesar, B. Influence of dipping time on uptake of preservative solution, adsorption, penetration and fixation of copper-ethanolamine based wood preservatives . Eur. J. Wood Prod. 67, 265–270 (2009). https://doi.org/10.1007/s00107-009-0317-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-009-0317-1