1. Introduction

Large-scale wind power bases are mostly located in the areas with rich wind energy and far from the load center. Because of the small capacity of local load, a vast amount of wind power needs to be delivered through a transmission channel to the load center. Wind power is highly intermittent; during the periods of large availability of wind energy, the lack of consumption space in local areas and the restriction of total transfer capability (TTC) of the transmission channel are two main reasons for wind power curtailment.

Many relevant studies focus on expanding consumption space for wind power in the local areas of large-scale wind power bases. A pair of studies [

1,

2] suggest that the curtailed wind power could be consumed by the energy-intensive load, which is located close to the large-scale wind power base and has better regulation flexibility than residential load. Two papers [

3,

4] studied the potential of deep peak regulation of thermal generation units and proposed a wind-thermal peak regulation trading mechanism to help consume wind power. However, through economic analysis [

5] revealed that blindly reducing the wind power curtailment using the supply side and demand side resources may not be cost-effective. References [

6,

7] show that a wind power generation system equipped with energy storage can smooth the fluctuation of wind power, but it needs a fairly large investment. Using the methods given above, during the periods of large availability of wind energy, wind power can be further consumed in the local areas by regulating energy-intensive load upward, regulating the output of thermal generation units deep downward and storing wind energy.

The above studies have provided methods that can effectively improve the wind power curtailment situation. However, the installed capacity of wind power in a large-scale wind power base is far too large; the curtailed wind power cannot be fully consumed through the above-mentioned methods. Delivering wind power through the transmission channel to the load center is still an important way to consume large-scale wind power. Reference [

8] shows that the flexible demand response in the load center can shift the load to wind power peak periods, which enables the receiving-side system to spare more available consumption space for wind power. However, large-scale wind power delivered through the transmission channel makes the transmission channel vulnerable [

9]. Therefore, enhancing TTC and making full use of the transmission channel is of great significance for wind power consumption.

TTC of the transmission channel is usually limited by its transient stability-constrained total transfer capability (still referred to as TTC) [

10], so TTC can be enhanced by improving system transient stability. Some studies have found that flexible AC transmission system (FACTS) devices could be utilized to improve transient stability besides their main function of controlling power flow [

11,

12,

13,

14]. FACTS devices including the unified power flow controller (UPFC) and the thyristor switched series capacitor (TSSC) use silicon controlled rectifiers (SCRs) instead of traditional mechanical switches. The development of silicon-coated gold nanoparticle technology enables FACTS devices to achieve super-resolution and quicker adjustment according to the system instructions [

15,

16]. Reference [

11] modulates the active power and reactive power using UPFC to improve the first swing stability and achieves enhancing TTC of long-distance transmission lines. The authors of [

12] designed a power oscillation damping controller which enables TSSC to have continuous reactance, and by decreasing the reactance between the sending and receiving ends, TTC can be enhanced. However, the main function of FACTS devices is not to improve the system’s transient stability; what is more, for the systems that do not have FACTS devices, installing them requires additional costs.

Transient stability analysis shows that some electrical parameters, such as the inertia constant and grid reactance, have great impacts on system transient stability [

17]. Due to the differences in the electrical parameters of thermal generation units, system electrical parameters and TTC change with thermal generation unit commitment. For a system with large-scale wind power integration, day-ahead thermal generation scheduling is necessarily made to ensure power balance, mostly with the objective of minimizing the generation cost, sometimes considering the objectives of maximizing the reliability of the power system and minimizing the emission [

18,

19]. However, no previous work on enhancing TTC by optimizing thermal generation schedules has been reported.

This paper presents a new method with which to enhance TTC based on the existing grid structure, which is by optimizing the day-ahead thermal generation schedules, and it can help reduce curtailed wind power for the sending-side system with large-scale wind power integration. This method is especially suitable for the sending-side system with thermal generation plants and large-scale wind power integration and the transmission channel in its existing grid structure, which is the common structure of large-scale wind power bases. The resources that are used in this method only involve the existing thermal generation plants, and it requires no further installment of devices. The main contributions are as follows:

The mechanism of the impact of thermal generation plant/unit commitment on TTC is revealed.

TTC is enhanced by optimizing the day-ahead thermal generation schedules, requiring no investment in installing additional devices. With the enhanced TTC, more wind power is allowed to be delivered through the transmission channel to the load center; therefore, the curtailed wind power is reduced.

The rest of the paper is organized as follows. In

Section 2 and

Section 3, the impact of enhancing TTC on reducing curtailed wind power and the mechanism of the impact of thermal generation plant/unit commitment on TTC are analyzed. In

Section 4, the optimal day-ahead thermal generation scheduling method to enhance TTC is proposed. In

Section 5, the case analysis is presented. Finally, the conclusions are given in

Section 6.

2. The Impact of Enhancing TTC on Reducing Curtailed Wind Power

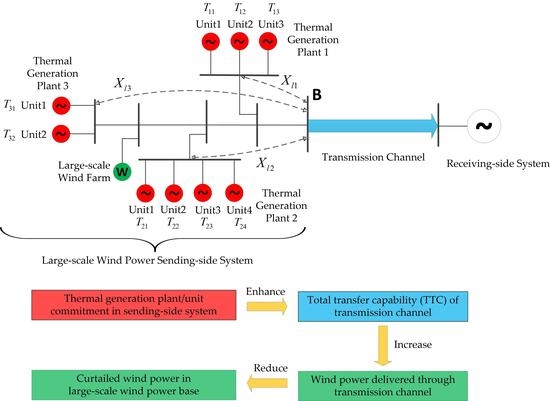

Figure 1 shows a schematic diagram of a sending-side system with large-scale wind power integration, a receiving-side system and the transmission channel between them. Assuming that during the periods of large availability of wind energy, wind power is curtailed, the impact of enhancing TTC on reducing curtailed wind power is analyzed below.

For the sending-side system, the wind power output is regarded as a negative load, and the power delivered through the transmission channel is regarded as a positive load. The equivalent load in the sending-side system is as follows:

where

is the total load in the sending-side system,

is the power delivered through the transmission channel and

is the wind power output.

The equivalent load is balanced with the thermal generation in the sending-side system as follows:

where

is the thermal generation in the sending-side system.

During the periods of large availability of wind energy, the power delivered through the transmission channel reaches TTC, and if the minimum allowable thermal generation

is greater than the equivalent load

, wind power needs to be curtailed, and the curtailed wind power is the sum of Area 1 and Area 2 during periods

in

Figure 2.

If TTC is enhanced, the power delivered through the transmission channel

can be increased; according to Equation (1), the equivalent load

is increased accordingly. Therefore, the curtailed wind power reduces from the sum of Area 1 and Area 2 to Area 2 in

Figure 2.

3. The Impact of Thermal Generation Plant/Unit Commitment on TTC

The TTC of the transmission channel is usually limited by its transient, stability-constrained total transfer capability, which is considered as a security constraint while making generation schedules. In fact, due to the differences of thermal generation plants and units in terms of their electrical parameters and their electrical distances from the transmission channel, thermal generation plant/unit commitment has a great impact on TTC.

As shown in

Figure 3, for a multi-generator sending-side system, while analyzing the impact of thermal generation plant/unit commitment on TTC, the wind farms and load are omitted. The online thermal generation units in the sending-side system are equivalent to one synchronous generator, and the receiving-side system is equivalent to an infinity bus system.

Under the condition that the system is able to stay transiently stable after a fault occurs, the maximum steady state power that can be delivered through the transmission channel in

Figure 3b represents TTC (it is not the actual TTC, but it can be used for qualitatively analyzing the impact of thermal generation plant/unit commitment on TTC). The system transient stability is evaluated by the stability of the synchronous generator rotor angle in the first swing after a fault occurs. The rotor motion equation of the equivalent synchronous generator of the sending-side system is shown in Equations (3) and (4):

where

,

,

,

,

are the rotor angle, internal voltage, inertia constant, mechanical and electrical power of the equivalent synchronous generator of the sending-side system, respectively.

is the acceleration of

.

is the maximum of

.

equals the steady state value of

, and it represents the steady state power delivered through the transmission channel.

is the magnitude of the infinity bus voltage, and the phase angle of the infinity bus voltage remains 0. Reactance

is the equivalent electrical distance between the transmission channel and the equivalent synchronous generator of the sending-side system.

is the reactance of the transmission channel.

According to equal area criterion [

20], if the rotor’s acceleration area

during the fault is equal to its maximum possible deceleration area

after the fault is removed, the system is in the transient stability critical state, and

reaches its maximum value

which represents TTC, as shown in

Figure 4.

According to Equations (3) and (4),

and

are both important factors in the system’s transient stability evaluation, so they have an impact on TTC. Due to the differences of thermal generation plants and units in their electrical distances from the transmission channel and their inertia constants, as shown in

Figure 3a, thermal generation plant/unit commitment has a great impact on

and

, and therefore, on TTC, and the detailed analysis is as follows.

3.1. The Impacts of Thermal Generation Plant Commitment on and TTC

The impact of

on TTC is analyzed through

Figure 5. If

decreases from

in

Figure 5a to

in

Figure 5b, according to Equation (4),

will increase from

to

(superscript “0” and “1” correspond to

Figure 5a,b, respectively). TTC in

Figure 5a is

, and assuming the power delivered through the transmission channel in

Figure 5b remains

, it can be seen that

and

, which means the system in

Figure 5b has not reached the transient stability critical state, and there is still space for

to increase; therefore,

. In conclusion, TTC increases with the decrease of

.

For the three thermal generation plants in the sending-side system in

Figure 3a, assuming

and ignoring the influences of other parameters, if only two thermal generation plants need to be online, then the plant commitment of Plant 1 and Plant 2 can obtain the minimum

and the maximum TTC.

3.2. The Impacts of Thermal Generation Unit Commitment on and TTC

The impact of

on TTC is analyzed through

Figure 6. If

increases from

in

Figure 6a to

in

Figure 6b, according to Equation (3),

will decrease, so the fault removal rotor angle

will decrease from

to

(superscript “0” and “2” correspond to

Figure 6a,b, respectively). TTC in

Figure 6a is

, and assuming the power delivered through the transmission channel in

Figure 6b remains

, it can be seen that

and

, which means the system in

Figure 6b has not reached the transient stability critical state, and there is still space for

to increase; therefore,

. In conclusion, TTC increases with

.

For each thermal generation plant that is scheduled to be online, its equivalent inertia constant changes with the thermal generation unit commitment inside the plant. TTC increases with the equivalent inertia constant of each online thermal generation plant.

5. Case Analysis

The proposed optimal day-ahead thermal generation scheduling method to enhance TTC was applied to the large-scale wind power base sending-side system in Gansu Province in China. The optimization models were solved using the above algorithms in MATLAB. TTC was calculated using the transient, stability-constrained continuation power flow method [

23], using the Power System Analysis Software Package (PSASP), which is widely used for power system calculations and simulations in China.

5.1. Test System Description

The simplified diagram of the large-scale wind power base sending-side system in Gansu Province is shown in

Figure 8. The receiving-side system is equivalent to an infinity bus system. Hexi Substation is the border node in the sending-side that the transmission channel connects to. Four thermal generation plants are involved; the capacities of the units in each plant are shown in

Table 1; and the relative parameters of each kind of unit are shown in

Table 2. The electrical distance parameters that describe the grid topology are shown in

Table 3 (the resistances of the lines are small and ignored). The base power is

in the system. While calculating the transient, stability-constrained TTC of the transmission channel, the transient models of the involved electronic components are used, and the relative parameters and the TTC calculation process are shown in the

Appendix A.

The original day-head generation schedules are shown in

Table 4. The four thermal generation plants are all online, and the thermal generation unit commitment and the generation schedule in each plant are based on the lowest generation cost rule. The corresponding original TTC is 4404 MW. Due to the restriction of TTC of the transmission channel, during period 1–10 (each period is one hour), the minimum allowable thermal generation is greater than the equivalent load, so the wind power is curtailed. The curtailed wind power is 5935 MWh.

5.2. Analysis of the Results of Day-Ahead Thermal Generation Schedule Optimization

Establish the day-ahead thermal generation plant commitment optimization model and solve the model using the method in

Section 4.2. The optimized day-ahead thermal generation plant commitment is obtained as shown in

Table 5.

For the online thermal generation plants of JC, ZY and JQ, establish the day-ahead thermal generation unit commitment, schedule optimization models and solve the models using the method in

Section 4.3, respectively. The optimized day-ahead thermal generation unit commitment and generation schedules are shown in

Table 6 and

Table 7.

The comparisons of the relative electrical parameters and generation costs of the sending-side system and the corresponding TTC before and after optimizing the day-head generation schedules are shown in

Table 8. The detailed process of how to get the results in

Table 8 is provided in the

supplementary materials.

As shown in

Table 8, by optimizing the day-ahead thermal generation schedules, the equivalent electrical distance between the transmission channel and the equivalent synchronous generator of the sending-side system decreases by 0.0483 p.u. and the equivalent inertia constant of the sending-side system increases by 7.57 s. The corresponding TTC is enhanced from 4404 to 5105 MW. The explanation of the TTC enhancement is as follows: Compared to the original day-head thermal generation schedules, the optimized generation schedules choose the thermal generation plants which are electrically closer to the transmission channel to be online, and shut down the BLS thermal generation plant which is the farthest plant from the transmission channel; therefore, the equivalent electrical distance between the transmission channel and the equivalent synchronous generator of the sending-side system is decreased; what is more, the optimized day-ahead thermal generation unit commitment inside each online plant chooses the thermal generation units with bigger inertia constants to be online; therefore, the equivalent inertia constant of the sending-side system is increased. Due to the decreased equivalent electrical distance, the electrical connection between the sending-side system and the transmission channel becomes tighter, and due to the increased equivalent inertia constant, the rotor angle accelerates slowly after a fault occurs, and this improves the transient stability of the system. Therefore, while the power delivered through the transmission channel is still 4404 MW, the system has not reached the transient stability critical state, and the power delivered through the transmission channel can increase to 5105 MW, which is the TTC after the day-head generation schedules are optimized.

Using the enhanced TTC, the curtailed wind power can be reduced. The comparation of curtailed wind power before and after optimizing the day-head generation schedules is shown in

Figure 9.

As shown in

Figure 9, the curtailed wind power is reduced by 4083 MWh, and the benefit from it is

$274,214 assuming the tariff of wind power is 67.16

$/MWh. As shown in

Table 8, the thermal generation cost increases by

$186,013. In general, the economic benefit brought by optimizing the day-ahead thermal generation schedules to enhance TTC is

$88,201. It can be seen that, for the purpose of enhancing TTC, some of the units which are electrically closer to the transmission channel and with bigger inertia are constant while those with higher generation costs (like the Unit 4 and Unit 5 in JC thermal generation plant) are chosen to be online, and that increases the generation cost. However, the benefit from consuming the curtailed wind power because of the enhanced TTC is more than the additional generation cost, and the general cost is reduced. Therefore, the proposed method is economically favorable.

5.3. Suitable Parameter Selection for MOPSO

While solving the day-ahead thermal generation unit commitment and schedule optimization models in

Section 4.3.1, we use the MOPSO in

Section 4.3.2, and the initial population, generation of random members, termination criterion and other parameters in MOPSO have certain effects on the results. Taking the day-ahead thermal generation unit commitment and schedule optimization model solution of JC thermal generation plant as an example, the suitable parameters for solving the models are selected through comparation and sensitivity analysis as follows.

1. Initial population

There are three commonly used initial solutions in the day-ahead thermal generation unit commitment and schedule optimization problem, and they are used as initial populations in MOPSO respectively, as follows:

Initial population A: day-ahead generation schedules obtained based on the lowest generation cost rule.

Initial population B: day-ahead generation schedules obtained based on the installation capacity proportion rule.

Initial population C: random day-ahead generation schedules.

The objective results of JC thermal generation plant obtained from the above three initial populations are shown in

Table 9. It can be seen in

Table 9 that the equivalent inertia constant results are the same; this is because the day-ahead thermal generation unit commitments obtained from these three different initial populations are the same. Initial population A can get the lowest thermal generation cost because it is originally obtained based on the lowest generation cost rule. Therefore, we chose initial population A as the initial population in

Section 5.2.

2. Generation of random members and inertia weight

In the velocity update equation (Equation (13)), the generation of random members

,

and the value of inertia weight

effect the global search capability of MOPSO.

Figure 10 shows the objective results based on different generation methods of random members and different values of inertia weight. In

Figure 10a,b, the random members are generated by uniform random sampling in [0,1] and Monte Carlo sampling in [0,1], respectively, and the inertia weights range from 0.4 to 2.4.

It can be seen from

Figure 10 that the generation method of random members has little effect on the results. However, the value of inertia weight significantly influences the results, and when the value is near 1.4, MOPSO gets the best global search capability, and this is because if the value of inertia weight is too small, the results will fall into the local optimal solution, and if the value of inertia weight is too big, the results may miss the global optimal solution. Therefore, we used uniformly random sampling to generate random members for simplicity, and we let the inertia weight take the value of 1.4 in

Section 5.2.

3. Termination criterion

The termination criterion, which is the maximum number of iterations of MOPSO should consider when converging on the objectives.

Figure 11 shows the convergence situation of the objectives as the number of iterations increases. It can be seen that when the number of iterations is more than 50, both equivalent inertia constant and thermal generation cost converge to their optimal values. Therefore, the maximum number of iterations is set to 55 as the termination criterion in

Section 5.2.

6. Conclusions

Enhancing TTC allows more wind power to be delivered through the transmission channel to the load center, and it is of great importance to help consume wind power in the large-scale wind power base sending-side system. This paper proposed a new method to enhance TTC based on the existing grid structure; namely, by optimizing the day-ahead thermal generation schedules. It can significantly enhance TTC, and therefore, reduce the curtailed wind power. The conclusions are as follows:

TTC increases with the decrease of the equivalent electrical distance between the transmission channel and the equivalent synchronous generator of the sending-side system. TTC increases with the inertia constant of the equivalent synchronous generator of the sending-side system.

Optimizing the day-ahead thermal generation plant commitment with the objective of minimizing the equivalent electrical distance between the transmission channel and the equivalent synchronous generator of the sending-side system, and then optimizing the day-ahead thermal generation unit commitment and schedule considering the objective of maximizing the equivalent inertia constant can significantly enhance TTC, and therefore, help consume the curtailed wind power.

The proposed method in this paper enhances TTC by optimizing the day-ahead thermal generation schedules; thus, it achieves a reduction of curtailed wind power, and it is of great significance to help improve wind power consumption in the sending-side system with large-scale wind power integration.