Abstract

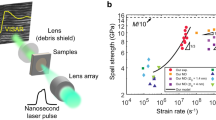

Metals are known to exhibit mechanical behaviour at the nanoscale different to bulk samples. This transition typically initiates at the micrometre scale, yet existing techniques to produce micrometre-sized samples often introduce artefacts that can influence deformation mechanisms. Here, we demonstrate the casting of micrometre-scale aluminium single-crystal wires by infiltration of a salt mould. Samples have millimetre lengths, smooth surfaces, a range of crystallographic orientations, and a diameter D as small as 6 μm. The wires deform in bursts, at a stress that increases with decreasing D. Bursts greater than 200 nm account for roughly 50% of wire deformation and have exponentially distributed intensities. Dislocation dynamics simulations show that single-arm sources that produce large displacement bursts halted by stochastic cross-slip and lock formation explain microcast wire behaviour. This microcasting technique may be extended to several other metals or alloys and offers the possibility of exploring mechanical behaviour spanning the micrometre scale.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kubin, L. P. Dislocations, Mesoscale Simulations and Plastic Flow 307 (Oxford Univ. Press, 2013).

Uchic, M. D., Shade, P. A. & Dimiduk, D. M. Plasticity of micrometer-scale single crystals in compression. Annu. Rev. Mater. Res. 39, 361–386 (2009).

Greer, J. R. & De Hosson, J. T. M. Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654–724 (2011).

Kraft, O., Gruber, P. A., Moenig, R. & Weygand, D. Plasticity in confined dimensions. Annu. Rev. Mater. Res. 40, 293–317 (2010).

Dehm, G. Miniaturized single-crystalline fcc metals deformed in tension: new insights in size-dependent plasticity. Prog. Mater. Sci. 54, 664–688 (2009).

Weinberger, C. R. & Cai, W. Plasticity of metal nanowires. J. Mater. Chem. 22, 3277–3292 (2012).

Huetsch, J. & Lilleodden, E. T. The influence of focused-ion beam preparation technique on microcompression investigations: lathe vs. annular milling. Scr. Mater. 77, 49–51 (2014).

Volkert, C. A. & Minor, A. M. Focused ion beam microscopy and micromachining. MRS Bull. 32, 389–395 (2007).

Bei, H., Shim, S., Miller, M. K., Pharr, G. M. & George, E. P. Effects of focused ion beam milling on the nanomechanical behavior of a molybdenum-alloy single crystal. Appl. Phys. Lett. 91, 111915 (2007).

Kiener, D., Motz, C., Rester, M., Jenko, M. & Dehm, G. FIB damage of Cu and possible consequences for miniaturized mechanical tests. Mater. Sci. Eng. 459, 262–272 (2007).

Shim, S., Bei, H., Miller, M. K., Pharr, G. M. & George, E. P. Effects of focused ion beam milling on the compressive behavior of directionally solidified micropillars and the nanoindentation response of an electropolished surface. Acta Mater. 57, 503–510 (2009).

Mompiou, F. et al. Source-based strengthening of sub-micrometer Al fibers. Acta Mater. 60, 977–983 (2012).

Johanns, K. E. et al. In-situ tensile testing of single-crystal molybdenum alloy fibers with various dislocation densities in a scanning electron microscope. J. Mater. Res. 27, 508–520 (2012).

Chisholm, C. et al. Dislocation starvation and exhaustion hardening in Mo alloy nanofibers. Acta Mater. 60, 2258–2264 (2012).

Rao, S. I. et al. Athermal mechanisms of size-dependent crystal flow gleaned from three-dimensional discrete dislocation simulations. Acta Mater. 56, 3245–3259 (2008).

Baumeister, G., Buqezi-Ahmeti, D., Glaser, J. & Ritzhaupt-Kleissl, H. J. New approaches in microcasting: permanent mold casting and composite casting. Microsyst. Technol. 17, 289–300 (2011).

Rögner, J., Lang, K. H., Baumeister, G. & Schulze, V. Microstructure and mechanical properties of micro tensile specimens made of CuAl10Ni5Fe4 produced by micro casting. Microsyst. Technol. 17, 301–311 (2011).

Tabata, T., Fujita, H., Yamamoto, S. & Cyoji, T. Effect of specimen diameter on tensile behaviors of aluminum thin wires. J. Phys. Soc. Jpn 40, 792–797 (1976).

Ng, K. S. & Ngan, A. H. W. Stochastic nature of plasticity of aluminum micro-pillars. Acta Mater. 56, 1712–1720 (2008).

Rao, S. I. et al. Atomistic simulations of cross-slip nucleation at screw dislocation intersections in face-centered cubic nickel. Philos. Mag. 89, 3351–3369 (2009).

Hussein, A. M., Rao, S. I., Uchic, M. D., Dimiduk, D. M. & El-Awady, J. A. Microstructurally based cross-slip mechanisms and their effects on dislocation microstructure evolution in fcc crystals. Acta Mater. 85, 180–190 (2015).

Dimiduk, D. M., Woodward, C., LeSar, R. & Uchic, M. D. Scale-free intermittent flow in crystal plasticity. Science 312, 1188–1190 (2006).

Kiener, D., Grosinger, W., Dehm, G. & Pippan, R. A further step towards an understanding of size-dependent crystal plasticity: in situ tension experiments of miniaturized single-crystal copper samples. Acta Mater. 56, 580–592 (2008).

Csikor, F. F., Motz, C., Weygand, D., Zaiser, M. & Zapperi, S. Dislocation avalanches, strain bursts, and the problem of plastic forming at the micrometer scale. Science 318, 251–254 (2007).

Devincre, B. & Kubin, L. Scale transitions in crystal plasticity by dislocation dynamics simulations. C. R. Phys. 11, 274–284 (2010).

Richeton, T., Dobron, P., Chmelik, F., Weiss, J. & Louchet, F. On the critical character of plasticity in metallic single crystals. Mater. Sci. Eng. A 424, 190–195 (2006).

Weiss, J. et al. Evidence for universal intermittent crystal plasticity from acoustic emission and high-resolution extensometry experiments. Phys. Rev. B 76, 224110 (2007).

Zaiser, M. & Moretti, P. Fluctuation phenomena in crystal plasticity - a continuum model. J. Stat. Mech. Theor. Exp. 2005, P08004 (2005).

Zaiser, M. & Nikitas, N. Slip avalanches in crystal plasticity: scaling of the avalanche cut-off. J. Stat. Mech. Theor. Exp. 2007, P04013 (2007).

Motz, C., Weygand, D., Senger, J. & Gumbsch, P. Initial dislocation structures in 3D-discrete dislocation dynamics and their influence on microscale plasticity. Acta Mater. 57, 1744–1754 (2009).

Staubwasser, W. On work-hardening of aluminium-single crystals (99.99-percent) and its interpretation. Acta Metall. 7, 43–50 (1959).

Diologent, F., Goodall, R. & Mortensen, A. Surface oxide in replicated microcellular aluminium and its influence on the plasticity size effect. Acta Mater. 57, 286–294 (2009).

Kiener, D. et al. Influence of external and internal length scale on the flow stress of copper. Int. J. Mater. Res. 98, 1047–1053 (2007).

Dieter, G. E. Mechanical Metallurgy 128 (McGraw-Hill, 1988).

Murr, L. E. Interfacial Phenomena in Metals and Alloys (Addison-Wesley, 1975).

Arsenlis, A. et al. Enabling strain hardening simulations with dislocation dynamics. Modelling Simul. Mater. Sci. Eng. 15, 553–595 (2007).

Acknowledgements

The experimental part of this work was sponsored by the Swiss National Science Foundation, Contract No 200020_156064/1. Part of the computations were supported by a grant of computer time from the DOD High Performance Computing Modernization Program, at the Aeronautical Systems Center/Major Shared Resource Center, USA. S.I.R. and W.A.C. acknowledge support of this work through a European Research Council Advanced Grant, ‘Predictive Computational Metallurgy’, ERC grant agreement no. 339081—PreCoMet. The authors wish to thank L. Kubin of the CNRS in France for frequent and helpful advice over the course of this project, H. van Swygenhoven, K. Hemker, O. Kraft, M. Legros, D. Weygand and P. Gumbsch for stimulating discussions, together with W. Dufour, C. Bacciarini, R. Charvet and C. Dénéréaz at EPFL for their contributions in designing and building the microtesting apparatus. We thank M. Cantoni and E. Oveisi at EPFL’s Interdisciplinary Center for Electron Microscopy (CIME) for their substantial contributions in producing electron micrographs in the Supplementary Information of this article and last but not least K. Schenk at EPFL who kindly measured the orientation of our wires using monocrystalline diffraction.

Author information

Authors and Affiliations

Contributions

J.K. and S.V. performed the experiments and produced all the experimental data; J.K., C.M., R.G. and A.M. developed the microcasting process; S.I.R. and W.A.C. conducted all the 3D dislocation dynamics simulations; J.K., S.I.R., W.A.C. and A.M. wrote the text; J.K., S.V., S.I.R., R.G. and A.M. produced figures; S.I.R. produced the films; J.K., S.I.R., S.V., W.A.C. and A.M. interpreted and discussed the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 3784 kb)

Supplementary Movie 1

Supplementary Movie 1 (AVI 25995 kb)

Supplementary Movie 2

Supplementary Movie 2 (AVI 6826 kb)

Supplementary Movie 3

Supplementary Movie 3 (AVI 21063 kb)

Supplementary Movie 4

Supplementary Movie 4 (AVI 10540 kb)

Supplementary Movie 5

Supplementary Movie 5 (AVI 19891 kb)

Supplementary Movie 6

Supplementary Movie 6 (AVI 10044 kb)

Rights and permissions

About this article

Cite this article

Krebs, J., Rao, S., Verheyden, S. et al. Cast aluminium single crystals cross the threshold from bulk to size-dependent stochastic plasticity. Nature Mater 16, 730–736 (2017). https://doi.org/10.1038/nmat4911

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4911