Abstract

The ZrO 2 scales formed on Zircaloy-4 PWR tubes during corrosion in steam in the temperature range of 1000–1300°C have been found to contain a metallic phase that is relatively rich in Sn. The precise composition of the metallic phase has not been determined. Most of the metallic phase is located in a line of metallic particles, which is oriented parallel to the alloy-scale interface and located near the center of the scale. The exact morphology of the scale on either side of the particle line has not been identified. The oxide between the metallic particles and the scale-steam interface contains very little Sn, except for a narrow zone adjacent to the scale-steam interface, which was formed in the beginning of the reaction. It appears that the scale between the metallic particles and the alloy-scale interface consists of thin columnar grains of ZrO 2 with a very fine metallic phase probably located at the ZrO 2 grain boundaries. The experimental evidence presently available indicates that the metallic phase exists in the scales at the reaction temperature. If the metallic particles were rich enough in Sn, then a liquid metallic phase would exist in the oxide during the reaction. Kinetic studies demonstrate that these particles move with respect to the scale-steam interface toward the center of the alloy during the course of the oxidation reaction. It appears that the presence of the line of metallic particles could, under certain conditions, markedly influence the mechanical properties of the oxide scales formed on Zircaloy-4.

Similar content being viewed by others

References

“Light-Water-Reactor Safety,” Quarterly Progress Report on Reactor Safety Programs Sponsored by the NRC Division of Reactor Safety Research, I, ORNL-TM-4914 (January–March 1975), Vol. I, Chap. 4.

“Light-Water-Reactor Safety,” Quarterly Progress Report on Reactor Safety Programs Sponsored by the NRC Division of Reactor Safety Research, I, ORNL-TM-5148 (July–September 1975).

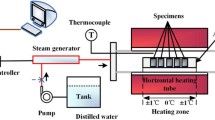

J. V. Cathcartet al., “Zirconium Metal-Water Oxidation Kinetics, I. Thermometry,” ORNL-5102.

“Light-Water-Reactor Safety,” Quarterly Progress Report on Reactor Safety Programs Sponsored by the NRC Division of Reactor Safety Research, I, ORNL-TM-4805 (October–December 1974), p. 92.

A. W. Lemmon, Jr., “Studies Relating to the Reaction between Zirconium and Water at High Temperatures,” Report No. BMI-1154 (TID-4500, 12 Ed.) (January 1957), pp. C-24–27.

J. B. Vander Sande and A. L. Bernent,J. Nucl. Mater. 52, 115 (1974).

K. Hauffe,Werkst. Korros. 22, 604 (1971).

K. Hauffe and V. Martinez, inMetal-Slag-Gas Reactions and Processes, Z. A. Foroulis and W. W. Smeltzer, eds. (The Electrochemical Society, Inc., Princeton, 1975), p. 355.

Author information

Authors and Affiliations

Additional information

This research was sponsored by the U.S. Nuclear Regulatory Commission under an interagency agreement with Union Carbide Corporation.

Rights and permissions

About this article

Cite this article

Yurek, G.J., Cathcart, J.V. & Pawel, R.E. Microstructures of the scales formed on zircaloy-4 in steam at elevated temperatures. Oxid Met 10, 255–276 (1976). https://doi.org/10.1007/BF00618247

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00618247