Abstract

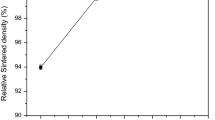

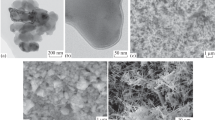

A study on the sintering of ultrafine SiC powders synthesized from elemental Si and CH4 using radio frequency (r.f.) induction plasma technology is reported. The powder had a particle size in the range of 40 to 80 nm and was composed of a mixture of α and β-SiC. It was subjected to pressureless sintering in an induction furnace in the presence of different sintering aids. With the addition of B4C (2.0 wt% B) by mechanical mixing, the powders could only be partially densified, with the highest value of 84.5% of theoretical density being achieved at 2170 °C for 30 min. Through the use of “in-flight” boron doping of the powder during the plasma synthesis step (1.65 wt % B), the ultrafine powder obtained could be densified to above 90% of its theoretical density at 2050 °C for 30 min. The addition of oxide sintering aids (7.0 wt % Al2O3 + 3.0 wt % Y2O3) by mehanical mixing produced sintered pellets of 95% of theoretical density at 2000 °C for 75 min. The Vicker’s microhardness of the sintered pellets in this case was as high as 31.2 GPa.

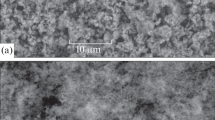

In order to improve our understanding of the basic phenomena involved, extensive microstructural (scanning electron energy microscopy: SEM), physical (shrinkage, weight loss, porosity, hardness) as well as chemical analysis (prompt gamma neutron activation analysis (PGNAA), energy dispersive spectroscopy (EDS), X-ray photoelectron spectroscopy (XPS), thermogravimetric analysis (TGA)) was carried out. This helped establish a relationship between the properties of the as-synthesized powder and their sintering properties. The influences of sintering temperature, sintering time, additive concentration, and powder purity on the densification behaviour of the plasma-synthesized powders was investigated. The results were compared with data obtained using commercial powder.

Similar content being viewed by others

References

C. M. Hollabaugh, D. E. Hull, L. R. Newkirk and J. J. Petrovic, J. Mater. Sci. 18 (1983) 3190.

G. J. Vogt, R. S. Vigil, L. R. Newkirk and M. Trkula, in Proceedings of 7th International Symposium on Plasma Chemistry, Eindhoven, Netherlands, July 1985.

A. Mitsui and A. Kato, Yogyo Kyokaishi (Japan) 94 (1986) 517.

H. R. Baumgartner and B. R. Rossing, "Pressureless sintering and properties of plasma-synthesized SiC powder, Ceramic transactions, Vol. 2: Silicon Carbide '87, edited by J. D. Cawley and C. E. Semler (American Ceramics Society, Westerville, OH, 1989) p. 3.

T. Kameyama, K. Sakanaka, A. Motoe, T. Tsunoda, T. Nakanaga, N. I. Wakayama, H. Takeo and K. Fukuda, J. Mater. Sci. 25 (1990) 1058.

P. R. Taylor and S. A. Pirzada, Mater. Manuf. Proc. 8 (1993) 501.

R. M. Salinger, Ind. Eng. Chem. Prod. Res. Develop. 11 (1972) 230.

J. Y. Guo and G. L. Zheng, Engng Chem. Metall. (China) 12 (1991) 1.

C. W. Zhu, G. Y. Zhao, V. Revankar and V. Hlavacek, J. Mater. Sci. 28 (1993) 659.

M. Endo, T. Sano, N. Urasato and M. Shiraishi, Yogyo-Kyokai-Shi (Japan) 95 (1987) 104.

P. C. Kong, T. T. Huang and E. Pfender, in Proceedings of 6th International Symposium on Plasma Chemistry, Montreal, Canada, July 1983, A-7-2.

P. Kong, R. M. Young, T. T. Huang and E. Pfender, in Proceedings of 7th International Symposium on Plasma Chemistry, Eindhoven, Netherlands, July 1985, B-4-4.

J. Y. Guo, F. Gitzhofer and M. I. Boulos, J. Mater. Sci. 30 (1995) 5589.

S. Prochazka, in Proceedings of the Conference on Ceramics for High Performance Applications, edited by J. J. Burke et al. (1973) p. 239.

J. A. Coppola, L. N. Hailey and C. H. McMurty, US Patent, No. 4, 124,667, Nov. 7 (1978).

J. E. Lane, C. H. Carter and R. F. Davis, J. Amer. Ceram. Soc. 71 (1988) 281.

R. H. J. Hannink, Y. Bando, H. Tanaka and Y. Inomata, J. Mater. Sci. 23 (1988) 2093.

R. M. Williams, B. N. Juterbock, S. S. Shinozaki, C. R. Peters and T. J. Whalen, Amer. Ceram. Soc. Bull. 64 (1985) 1385.

W. Bocker, H. Landfermann and H. Hausner, Powder Metall. Int. 10 (1978) 87.

K. A. Schwetz and A. Lipp, Sci. Ceram. 10 (1980) 149.

D. H. Stutz, S. Prochazka and J. Lorenz, J. Amer. Ceram. Soc. 68 (1985) 479.

S. Shinozaki, R. M. Williams, B. N. Juterbock, W. T. Dorlon, J. Hangas and C. R. Peters, Amer. Ceram. Soc. Bull. 64 (1985) 1389.

M. Omori and H. Takei, J. Amer. Ceram. Soc. 65 (1982) C-92.

M. A. Mulla and V. D. Krstic, Ceram. Bull. 70 (1991) 439.

S. K. Lee and C. H. Kim, J. Amer. Ceram. Soc. 77 (1994) 1655.

J. Kondo and G. Saiki, Ceram. Trans. 1A, Amer. Ceram. Soc. (1988) 285.

T. J. Carbone and B. R. Rossing, in Proceedings of 2nd International Symposium on Ceramic Materials and Components for Engines, West Germany, April 14-17 (1986).

O. Croix, M. Gounot, P. Bergez, M. Luce and M. Cauchetier, Paper presented at the 7th Cimtec, Montecatini, Terme, Italy, June 24-30 (1990).

K. M. Rigtrup and R. A. Cutler, in “Ceramic transaction, “ Vol. 2. Silicon Carbide ”87, edited by J. D. Cawley and C. E. Semler (American Ceramics Society, Westerville, OH, 1989) p. 17.

A. K. Misra, J. Amer. Ceram. Soc. 74 (1991) 345.

S. Futaki, Y. Shimizu, K. Shiraishi, Y. Moriyoshi, T. Sato and T. Sakai, J. Mater. Sci. 22 (1987) 4331.

C. D. Wagner, W. M. Riggs, L. E. Davis, J. F. Moulder and G. E. Muilenberg (eds), “Handbook of X-ray photoelectron spectroscopy” (Perkin-Elmer Corp., 1978).

A. W. Czanderna (ed.), “Methods of surface analysis” (Elsevier ScientiÞc Publishing Company, Amsterdam, 1975).

“JANAF Thermochemistry Tables”, J. Phys. Chem. Ref. Data. 14 (1985) Suppl. 1.

M. J. Aziz, E. Nygren, J. F. Hays and D. Turnbull, J. Appl. Phys. 57 (1985) 2233.

R. Browning, J. L. Smialek and N. S. Jacobson, Adv. Ceram. Mater. 2 (1987) 773.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

GUO, J.Y., GITZHOFER, F., BOULOS, M.I. et al. Study of the sintering properties of plasma synthesized ultrafine SiC powders. Journal of Materials Science 32, 5257–5269 (1997). https://doi.org/10.1023/A:1018602508405

Issue Date:

DOI: https://doi.org/10.1023/A:1018602508405