Conclusions

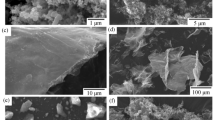

A comparative evaluation of the methods of obtaining corundum suspensions with a glass phase was conducted. Three methods were studied: dry milling in a metallic vibrational mill followed by a HCl wash to remove the iron contaminant and subsequent suspension; suspension of a powder dry-milled in a vibrational mill having a corundum lining; and additional wet milling in an acidic medium using a corundum-lined ball mill.

It was established that wet milling of alumina with a glass phase in an acidic medium permits one to obtain castings having a strength twice higher after removing from the mold and 25–30 times higher after drying. In this case, the duration of the slip preparation processes decreases considerably.

The strength of the castings made from the wet-milled alumina increases rapidly with decreasing moisture content in them (hydraulic setting) in contrast to the strength of the castings obtained from the alumina powder that was dry milled in a metallic vibrational mill and acid-washed. This makes it possible to carry out machining of the dry unfinished product using diamonds and to decrease the number of rejections of intricate products by 30–35%.

It was shown that the increased strength of the castings obtained according to the third method is due to the retention (realization) of the binding properties of aluminum chlorides formed during the process of milling in the acidic medium and due to the formation of calcium hydrosilicates in the system.

The structure and the properties of the ceramics based on the castings obtained according to different methods are very close to each other.

Similar content being viewed by others

Literature cited

K. A. Krasotin, D. B. Min'kov, T. S. Makarova et al., Ogneupory, No. 11, 7–14 (1973).

V. V. Primachenko, N. V. Pitak, L. M. Kolesnikov, and T. A. Zadorozhnaya, in: Production of Special Refractories [in Russian], Issue 6, Minchermet SSSR, Metallurgiya, Moscow (1978), pp. 58–62.

T. J. Taylor, J. Can. Ceram. Soc.,38, 47–55 (1969).

D. N. Poluboyarinov, V. L. Balkevich, and R. Ya. Popil'skii, High-Alumina Ceramics and Refractories [in Russian], Gosstroiizdat, Moscow (1960).

I. S. Kainarskii, É. V. Degtyareva, and I. G. Orlova, Corundum Based Refractories and Ceramics [in Russian], Metallurgiya, Moscow (1981).

I. S. Kainarskii, É. V. Degtyareva, and G. E. Kalita, Ogneupory, No. 6, 44–51 (1977).

G. V. Kukolev and A. G. Karaulov, ibid., No. 4, 168–178 (1963).

A. G. Dobrovol'skii, Slip Casting [in Russian], Metallurgiya, Moscow (1977).

Yu. E. Pivinskii and A. G. Pomashin, Quartz Ceramics [in Russian], Metallurgiya, Moscow (1974).

Yu. E. Pivinskii, Ogneupory, No. 2, 34–42 (1978).

Yu. E. Pivinskii, ibid, No. 6, 39–46 (1980).

Yu. E. Pivinskii and P. L. Mityakin, ibid., No. 5, 48–52 (1981).

Yu. E. Pivinskii, ibid., No. 6, 49–60 (1982).

Inventor's Certificate No. 717009; É. V. Degtyareva, I. I. Kabakova, E. B. Skorodumova, et al., Byull. Izobret., No. 7, 111 (1980).

É. V. Degtyareva, I. I. Kabakova, E. B. Skorodumova et al., Ogneupory, No. 2, 39–44 (1982).

V. L. Balkevich, Engineering Ceramics [in Russian], Stroiizdat, Moscow (1984).

R. Ya. Popil'skii and Yu. E. Pivinskii, Compaction of Ceramic-Body Powders [in Russian], Metallurgiya, Moscow (1983).

Yu. E. Pivinskii and T. F. Baranova, Ogneupory, No. 6, 22–25 (1984).

I. I. Kabakova, E. B. Skorodumova, É. V. Degtyareva, and E. D. Lisovaya, Ogneupory, No. 7, 51–55 (1982).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 12, pp. 4–9, December, 1985.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Skorodumova, E.B., Kabakova, I.I. et al. Evaluation of the production methods and the properties of corundum suspensions. Refractories 26, 651–658 (1985). https://doi.org/10.1007/BF01389987

Issue Date:

DOI: https://doi.org/10.1007/BF01389987