Abstract

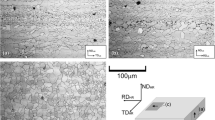

The activation of deformation mechanisms in magnesium alloys is Schmid factor-related. The concept of a generalized Schmid factor (G-SF) and a corresponding calculation method were proposed. The G-SF was calculated under a general stress state of plate rolling to discuss the rollability of a textured AZ31B magnesium alloy in terms of the Schmid factor criterion. A low reduction per pass (RPP) is favorable for rollability. The G-SF for basal slip systems of grains in the basal orientation remained constant, but it increased for (0-110)[2-1-10] and (1-100)[11-20] prismatic slip systems with a decrease in RPP. Similarly, the G-SF for all pyramidal slip systems and contraction twinning systems increased with a decrease in RPP. The rollability benefits from such a development trend and makes the synchronous activation of deformation modes possible.

Similar content being viewed by others

References

R. Von Mises, Mechanik der festen Körper im plastisch deformablen Zustand, Göttin. Nachr. Math. Phys., 1913, 1, p 582–592

X.Y. Lou, M. Li, R.K. Boger, S.R. Agnew, and R.H. Wagoner, Hardening Evolution of AZ31B Mg Sheet, Int. J. Plast., 2007, 23, p 44–86

S.R. Agnew, M.H. Yoo, and C.N. Tome, Application of Texture Simulation to Understanding Mechanical Behavior of Mg and Solid Solution Alloys Containing Li or Y, Acta Mater., 2001, 49, p 4277–4289

J. Koike, T. Kobayashi, T. Mukai, H. Watanabe, M. Suzuki, K. Maruyama, and K. Higashi, The Activity of Non-basal Slip Systems and Dynamic Recovery at Room Temperature in Fine-Grained AZ31B Magnesium Alloys, Acta Mater., 2003, 51, p 2055–2065

Z. Keshavarz and M.R. Barnett, Observation of Deformation Modes in Mg-3Al-1Zn, Mater. Sci. Forum, 2005, 29, p 382–386

S.R. Agnew, J.W. Senn, and J.A. Horton, Mg Sheet Metal Forming: Lessons Learned from Deep Drawing Li and Y Solid-Solution Alloys Magnesium, JOM, 2006, 58, p 62–69

L. Jiang, J.J. Jonas, A.A. Luo, A.K. Sachdev, and S. Godet, Twinning-Induced Softening in Polycrystalline AM30 Mg Alloy at Moderate Temperatures, Scr. Mater., 2006, 54, p 771–775

M.R. Barnett, Twinning and the Ductility of Magnesium Alloys Part I: “Tension” Twins, Mater. Sci. Eng. A, 2007, 464, p 1–7

M.R. Barnett, Twinning and the Ductility of Magnesium Alloys Part II. “Contraction” Twins, Mater. Sci. Eng. A, 2007, 464, p 8–16

C.D. Barrett, H. El-Kadiri, and M.A. Tschopp, Breakdown of the Schmid Law in Homogeneous and Heterogeneous Nucleation Events of Slip and Twinning in Magnesium, J. Mech. Phys. Solids, 2012, 60, p 2084–2099

D.W. Brown, S.R. Agnew, M.A.M. Bourke, T.M. Holden, S.C. Vogel, and C.N. Tomé, Internal Strain and Texture Evolution during Deformation Twinning in Magnesium, Mater. Sci. Eng. A, 2005, 399, p 1–12

M.R. Barnett, Z. Keshavarz, A.G. Beer, and X. Ma, Non-Schmid Behavior during Secondary Twinning in a Polycrystalline Magnesium Alloy, Acta Mater., 2008, 56, p 5–15

R.L. Xin, M.Y. Wang, X.X. Huang, C.F. Guo, and Q. Liu, Observation and Schmid Factor Analysis of Multiple Twins in a Warm-Rolled Mg-3Al-1Zn Alloy, Mater. Sci. Eng. A, 2014, 596, p 41–44

B.S. Wang, L.P. Deng, N. Guo, Z.R. Xu, and Q. Li, EBSD Analysis of 10-12 Twinning Activity in Mg-3Al-1Zn Alloy during Compression, Mater. Charact., 2014, 98, p 180–185

G.S. Song, S.H. Zhang, L. Zheng, and L.Q. Ruan, Twinning, Grain Orientation and Texture Variation of AZ31 Mg Alloy during Compression by EBSD Tracing, J. Alloys Compd., 2011, 509, p 6481–6488

F. Lv, F. Yang, Q.Q. Duan, T.J. Luo, Y.S. Yang, S.X. Li, and Z.F. Zhang, Tensile and low-Cycle Fatigue Properties of Mg-2.8% Al-1.1% Zn-0.4% Mn Alloy Along the Transverse and Rolling Directions, Scr. Mater., 2009, 61, p 887–890

S.H. Park, S.G. Hong, B.H. Lee, W. Bang, and C.S. Lee, Low-Cycle Fatigue Characteristics of Rolled Mg-3Al-1Zn Alloy, Int. J. Fatigue, 2010, 32, p 1835–1842

M.D. Nave and M.R. Barnett, Microstructures and Textures of Pure Magnesium Deformed in Plane-Strain Compression, Scr. Mater., 2004, 51, p 881–885

Y. Chino, K. Kimura, M. Hakamada, and M. Mabuchi, Mechanical Anisotropy Due to Twinning in an Extruded AZ31 Alloy, Mater. Sci. Eng. A, 2008, 485, p 311–317

S. Zaefferer, A Study of Active Deformation Systems in Titanium Alloys: Dependence on Alloy Composition and Correlation with Deformation Texture, Mater. Sci. Eng. A, 2003, 344, p 20–30

S.F. Chen, H.W. Song, S.H. Zhang, M. Cheng, C. Zheng, and M.G. Lee, An Effective Schmid Factor in Consideration of Combined Normal and Shear Stresses for Slip/Twin Variant Selection of Mg-3Al-1Zn Alloy, Scr. Mater., 2019, 167, p 51–55

D. Xia, X. Chen, G. Huang, B. Jiang, A. Tang, H. Yang, S. Gavras, Y. Huang, N. Hort, and F. Pan, Calculation of Schmid Factor in Mg Alloys: Influence of Stress State, Scr. Mater., 2019, 171, p 31–35

T. Mukai, M. Yamanoi, H. Watanabe, and K. Higashi, Ductility Enhancement in AZ31 Magnesium Alloy by Controlling Its Grain Structure, Scr. Mater., 2001, 45, p 89–94

S.R. Agnew, J.A. Horton, T.M. Lillo, and D.W. Brown, Enhanced Ductility in Strongly Textured Magnesium Produced by Equal Channel Angular Processing, Scr. Mater., 2004, 50, p 377–381

R. Gehrmann, M.M. Frommert, and G. Gottstein, Texture Effects on Plastic Deformation of Magnesium, Mater. Sci. Eng. A, 2005, 395, p 338–349

J.A. del Valle, F. Carreno, and O.A. Ruano, Influence of Texture and Grain Size on Work Hardening and Ductility in Magnesium-Based Alloys Processed by ECAP and Rolling, Acta Mater., 2006, 54, p 4247–4259

G.S. Duan, B.L. Wu, X.H. Du, G. Zhao, Y.D. Zhang, X. Zhao, L. Zuo, and C. Esling, The Microstructure Evolution in AZ31B Alloy during Multi-pass Cold Rolling to a High Reduction, Mater. Sci. Eng. A, 2015, 620, p 120–128

X.H. Du, M. Hong, G.S. Duan, C.B. Wei, E.P. Jiang, M. Zhang, B.L. Wu, Y.D. Zhang, and C. Esling, Excellent Cold Rollability in a Single Pass of an Mg-4Er (wt.%) Alloy, Int. J. Mater. Res., 2015, 106, p 15–21

W. Prager, Introduction to Mechanics of Continua, Dover Publications, New York, 2004, p 43

H.C. Wu, Continuum Mechanics and Plasticity, CRC Press, Boca Raton, 2005, p 45

L.G. Johnson, Theory and Technique of Variation Research, Elsevier Publishing Company, Amsterdam, 1964, p 105

O. Hoffman and G. Sachs, Introduction to the Theory of Plasticity for Engineers, McGraw-Hill, New York, 1953, p 276

S. Suwas, G. Gottstein, and R. Kumar, Evolution of Crystallographic Texture during Equal Channel Angular Extrusion (ECAE) and Its Effects on Secondary Processing of Magnesium, Mater. Sci. Eng. A, 2007, 471, p 1–14

N. Stanford and M. Barnett, Effect of Composition on the Texture and Deformation Behaviour of Wrought Mg Alloys, Scr. Mater., 2008, 58, p 179–182

S. Yi, I. Schestakow, and S. Zaefferer, Twinning-Related Microstructural Evolution during Hot Rolling and Subsequent Annealing of Pure Magnesium, Mater. Sci. Eng. A, 2009, 516, p 58–64

T. Mayama, M. Noda, R. Chiba, and M. Kuroda, Crystal Plasticity Analysis of Texture Development in Magnesium Alloy during Extrusion, Int. J. Plast., 2011, 27, p 1916–1935

M.J. Philippe, C. Esling, and B. Hocheid, Role of Twinning in Texture Development and in Plastic Deformation of Hexagonal Materials, Textures Microstruct., 1988, 7, p 265–301

R. Cottam, J. Robson, G. Lorimer, and B. Davis, Dynamic Recrystallization of Mg and Mg-Y Alloys: Crystallographic Texture Development, Mater. Sci. Eng. A, 2008, 485, p 375–382

E. Schmid, Beitrage zur Physik und Metallographie des Magnesiums, Z. Elektrochem., 1931, 37, p 447–459

P.W. Bakarian and C.H. Mathewson, Slip and Twinning of Magnesium Single Crystals at Elevated Temperatures, Trans. AIME, 1943, 152, p 226–231

E.C. Burke and W.R. Hibbard, Plastic Deformation of Magnesium Single Crystals, Trans. Metall. Soc. AIME, 1952, 194, p 295–303

S.S. Hsu and B.D. Cullity, On the Torsional Deformation and Recovery of Single Crystals, Trans. AIME, 1954, 200, p 305–312

H. Conrad and W.D. Robertson, Effect of Temperature on the Flow Stress and Strain-Hardening Coefficient of Magnesium Single Crystals, Trans. AIME, 1957, 209, p 503–513

R.E. Reed-Hill and W.D. Robertson, Additional Modes of Deformation Twinning in Magnesium, Acta Metall., 1957, 5, p 717–727

R.E. Reed-Hill and W.D. Robertson, Deformation of Magnesium Single Crystals by Non Basal Slip, Trans. TMS-AIME, 1957, 220, p 496–502

X.X. Wang, P.L. Mao, Z. Liu, Z. Wang, and L. Zhou, Nucleation and Growth Analysis of 10-12 Extension Twins in AZ31 Magnesium Alloy during In Situ Tension, J. Alloys Compd., 2020, 817, p 152967

Acknowledgments

The authors gratefully acknowledge the financial support from the National Foundation of Natural Science of China (Grant No. 51371121).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, B., Song, L., Wan, G. et al. Distribution of Generalized Schmid Factor in Euler Orientation Space and Rollability of AZ31B Alloy with Basal Texture. J. of Materi Eng and Perform 29, 8145–8155 (2020). https://doi.org/10.1007/s11665-020-05279-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05279-7