Abstract

We have investigated the effect of adhesion force on the frictional properties of a nanostripe structure composed of a combination of gold (Au) and iron (Fe). Relative humidity (RH) was controlled from 10%–80% during the friction experiment by atomic force microscopy. Au sputtered and Fe sputtered on Si samples were used for comparison. The nanostripe surface showed characteristic frictional property, which differed from that of Au and Fe. The adhesion force of nanostripe was comparable to that of Fe, and the frictional property of nanostripe was independent of RH. However, friction force is finite at the normal load of zero, and friction force non-linearly increased with increasing normal load. We will discuss the reason for the different trends between Au and Fe and nanostripe.

Export citation and abstract BibTeX RIS

1. Introduction

Factors that have an effect on frictional properties in nanoscale are surface energy and chemical composition and the arrangement of atoms and molecules. If we control a surface chemical composition using self-assembled monolayer (SAM), we can draw conclusions about the effect of the surface energy and chemical composition on the frictional properties in nanoscale.1,2) For a fixed normal load, the absolute friction force decreased as COOH/COOH > CH3/CH3 > COOH/CH3. This trend is the same as the trend of a magnitude of adhesion force, COOH/COOH > CH3/CH3 > COOH/CH3. This indicates that there is a direct correlation between the friction and adhesion force. On the other hand, the effect of humidity on the frictional properties of a SAM surface was also observed.3) When the surface was covered with methyl (−CH3) end group, which showed a hydrophobic surface, the coefficient of friction was independent of the relative humidity (RH). On the other hand, when the surface was covered with hydroxyl (−OH) end groups, which showed a hydrophilic surface, the coefficient of friction decreased with increasing RH. On a hydrophilic surface, adsorbed water layers will lower its surface energy as the humidity increases, and will affect its frictional property. The arrangement of atoms4–6) and molecules7) also has an effect on the frictional property. In the case of the atomic arrangement, a flat and smooth surface was prepared to measure the friction and the anisotropy of friction with respect to the atomic arrangement was observed.4–6) In addition, superlubricity, which realizes virtually zero friction, was also observed.5)

Surface texturing has been used extensively to improve the tribological properties of machine elements, such as sliding contact elements,8–14) magnetic storage disk surfaces15,16) and mechanical face seals.17,18) Many studies have shown that surface texturing offers good performance from boundary lubrication to hydrodynamic lubrication.19–21)

We have developed a novel nanopatterning method for nanostripe fabrication that incorporates a multilayer film and a microscale slope array.22) Furthermore, we have proposed a design concept for nanostripe structures in tribological applications.23) This nanostripe surface structure would be a promising candidate for a surface utilizing the characteristics of friction in nanoscale, because a nanostripe surface has a nanostructure reflecting the different materials, which have different surface energy. In addition, there is a possibility that the adsorption property of water is different from the uniform surface by reducing the size of the material that appeared on the surface, which was realized by nanostripe structure. When the surface of the water is curved at nanoscale such as a bubble, droplet and meniscus, its surface tension is theoretically expected to be smaller than that of a planar interface.24) Recently, it was experimentally indicated that the effective surface tension of the meniscus of the radius-of-curvature below 25 nm decreases to less than 20% of the bulk value.25) Therefore, detailed analysis of the frictional property of nanostructured materials using nanostripe can expect to show specific frictional property, which differs from that of bulk.

Here, we analyzed the effect of adhesion on the frictional properties using nanostripe structures. The effect of humidity on the relationship between adhesion and friction was analyzed.

2. Experimental methods

2.1. Fabrication of the nanostrip

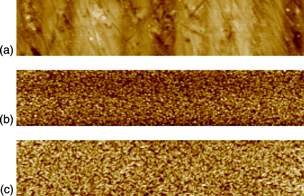

The fabrication sequence for the textured surfaces involved three steps. First, microgrooves were fabricated on a Si(100) substrate using photolithography. Then, iron (Fe) and gold (Au) multilayer film was deposited by physical vapor deposition. The thickness of each layer was 250 nm. Finally, the substrate was polished and different materials appeared on the surface as parallel stripes. Details are given in other literature.22,23,26,27) Figure 1 shows the atomic force microscopy (AFM) images of (a) a fabricated nanostripe surface, and (b) Au and (c) Fe sputtered on flat Si samples.

Fig. 1. (Color online) AFM images of (a) a fabricated nanostripe surface, and (b) Au and (c) Fe sputtered on flat Si samples. Scan size is 10 × 2 μm.

Download figure:

Standard image High-resolution image2.2. Tribological examination

Tribological examinations were performed using AFM (Nanoscope, MultiMode 8, Bruker Corp.). All AFM observations were performed at RT using a V-shaped silicon nitride cantilever with a spring constant of about 0.4 N m−1 for deflection and radius-of-curvature of a tip of about 20 nm (commercial). The normal load was varied from approximately 0–50 nN. The sliding velocity was varied from 20 μm s−1. The AFM unit was placed in a home-built environmental chamber equipped with a hygrometer. The RH was controlled by mixing dry air and humid air, and varied from 10%–80%. Friction measurement was performed in a 10 × 2 μm area. Adhesion force, which was evaluated from the force curve, was measured at 64 × 64 points in 5 × 5 μm and the averaged pull-off force measured at all points. The samples were nanostripe surface composed with Fe and Au. For comparison, we also used Au sputtered (contact angle of water was about 60°) and Fe sputtered (contact angle of water was about 118°) on Si samples.

3. Results and discussion

3.1. Results

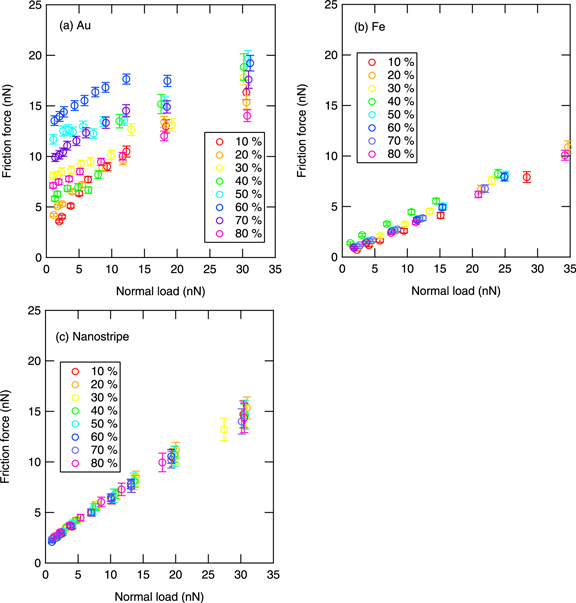

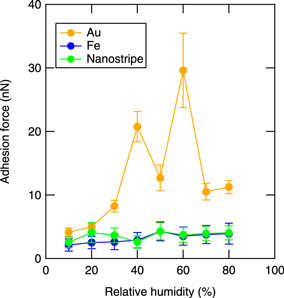

The frictional properties of Au, Fe and nanostripe surface are shown in Fig. 2. The frictional property of the Au surface was strongly affected by the RH. In addition, the friction force non-linearly increased with increasing normal load. On the other hand, the frictional property of the Fe surface was independent of RH and the friction force was proportional to the normal load. Furthermore, the friction force of Fe was lower than that of Au. The nanostripe surface showed a frictional property which differs from the Au and Fe surface. Friction force is finite at the normal load of zero. And the friction force non-linearly increased with increasing normal load, although the friction force of nanostripe was comparable to that of Au at RH of 10%. The water contact angle of the Au, Fe and nanostripe was about 60°, 118° and 75°, respectively. This result indicated that the frictional property of a hydrophilic surface such as Au was strongly affected by the RH, but the frictional property of a hydrophobic surface such as Fe was independent of RH. The nanostripe surface showed interesting results, where the frictional property was independent of RH, but the friction force non-linearly increased with increasing normal load despite the nanostripe surface being hydrophilic. Figure 3 shows the variation of adhesion force with RH. The adhesion force of Au had a maximum value at an RH of 60%. Correspondingly, the friction force of Au was largest at RH of 60%. Therefore, it is obvious that the friction force was strongly affected by the RH. On the other hand, the adhesion force of Fe and nanostripe was quite low compared with that of Au, although they gradually increased with increasing RH.

Fig. 2. (Color online) Frictional properties of (a) Au, (b) Fe and (c) nanostripe surfaces measured by AFM.

Download figure:

Standard image High-resolution imageFig. 3. (Color online) Adhesion force measured under RH from 10%–80%.

Download figure:

Standard image High-resolution image3.2. Discussion on the frictional property of Au surface

In order to analyze the non-linear frictional property of Au, we assume the friction measured using AFM is a single asperity contact and no wear. Here, assuming the contact area is A under normal load L, friction force is expressed as a product of A and the interfacial shear strength per unit area (τ).

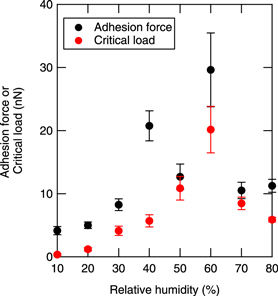

In this case, we observed the finite adhesion force between the two surfaces, and Johnson–Kendall–Roberts (JKR) theory was adopted to explain the frictional property observed. According to the previous report,28) the JKR equation can then be rewritten in the following compact non-dimensional form,

where the load (L) and friction (F) have been parameterized in terms of the critical load (Lc) and critical friction (Fc),

The critical load and critical friction are given by,

where, R is the tip radius, γ is the interfacial adhesion energy, Ac is the critical contact area and K is the reduced elastic modulus of the two materials. Using Eq. (2), we fitted the friction data and obtained Fc, Lc, Ac and τ. The results are summarized in Table I. Figure 4 shows the comparison between the adhesion force and critical load with respect to RH. We observed good correlation between the adhesion force and critical load. Therefore, the frictional property of the hydrophilic Au surface was governed by the adhesion between the tip and sample, which depends on the RH. Here, we consider the factors governing the friction of the Au surface. According to the previous results,29–31) it was also observed that the adhesion force exhibited transition-like behavior, that is, the adhesion force increased with RH and then decreased after a maximum. It is considered that there are three regimes, i.e. the van der Waals force regime, mixed van der Waals force regime and interplay regime. (I) In the van der Waals force regime, when the RH is less than 30%, the adhesion force is restricted to van der Waals interaction between the tip and sample. Consequently, no capillary necks develop and the adhesion force is unchanged. (II) In the mixed van der Waals regime, the adhesion force has contributions from van der Waals force and capillary force with increasing RH. (III) In the interplay regime, the adhesion force decreases with increasing RH. This is because the delicate interplay between capillary force and forces related to the chemical bonding of water molecules depresses the overall adhesion forces.

Table I. Estimated parameters by fitting of the frictional property of Au using Eq. (2).

| Relative humidity (%) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

|---|---|---|---|---|---|---|---|---|

| ∣Lc∣ (nN) | 0.34 | 1.19 | 4.12 | 0.87 | 10.86 | 20.15 | 8.47 | 5.89 |

| Fc (nN) | 0.74 | 1.42 | 2.76 | 3.52 | 4.39 | 5.58 | 3.90 | 2.68 |

| τ (GPa) | 1.40 | 1.17 | 1.00 | 1.02 | 0.83 | 0.70 | 0.87 | 0.76 |

| γ (mJ m−2) | 3.63 | 12.64 | 43.76 | 60.38 | 115.3 | 213.8 | 89.86 | 62.50 |

| Ac (nm2) | 0.53 | 1.21 | 2.77 | 3.44 | 5.29 | 7.99 | 4.48 | 3.52 |

Fig. 4. (Color online) Comparison between the adhesion force and critical load.

Download figure:

Standard image High-resolution imageThe critical friction had a maximum of about 11 nN at RH of 60%. As expressed in Eq. (1), friction force is expressed as a product of A and the τ. Change of A and τ with respect to the RH indicates that the variation of critical friction force is governed by the critical contact area. On the basis of this result, we considered the model of friction. When the RH is low, the amount of water adsorbed on the tip and substrate might be small. Therefore, a meniscus bridge would be formed between an asperity and substrate. This led to the small contact area and small adhesion force. When the RH becomes as large as about 60%, the amount of water adsorbed on surfaces might increase and a meniscus bridge would formed between a tip radius and substrate. As a result, the contact area and adhesion force became large. When the RH is smaller than 60%, friction force would be the shear of the meniscus bridge. When the RH is larger than 70%, a water layer might cover the whole surface and the shear is governed by the water layer. This would potentially lead to the reduction of friction force and shear strength. As a result, the adhesion and friction forces represented the maximum value at an RH of 60%.

3.3. Discussion on the frictional property of Fe surface

The adhesion force of Fe was quite low compared with that of Au, although it slightly increased with increasing RH. The frictional property of the Fe surface was independent of RH and the friction force was proportional to the normal load. In addition, the friction force of Fe is lower than that of Au. These results indicated that the contribution of capillary force to the adhesion force is quite small. For a hydrophobic surface such as Fe, the adhesion and friction forces are governed by van der Waals interaction between the tip and sample. The slight increase of the adhesion force associated with RH is thought to be due to the change of the hydrophilic tip surface condition associated with RH. The coefficient of friction estimated from the fitting of friction data is about 0.29 and was unaffected by the change of RH. This value is apparently identical to the coefficient of friction of pure Fe measured in a macroscopic friction test.32) In addition, the coefficient of friction measured in the macroscopic friction test was almost constant (∼0.3) from RH of 10%–50%, which agreed with our AFM result. This indicates that the frictional property of pure Fe was comparable and was independent of RH, even though the measurement scale was widely varied.

3.4. Discussion on the frictional property of nanostripe surface

The adhesion force of nanostripe was comparable to that of Fe. However, the frictional property of nanostripe was different from that of Fe. The frictional property of nanostripe was independent of RH, but friction force is finite at the normal load of zero. And the friction force non-linearly increased with increasing normal load, although the friction force of nanostripe was comparable to that of Au at RH of 10%. Using Eq. (2), we fitted the friction data and obtained Fc, Lc, Ac and τ. The results are summarized in Table II. Each value is almost constant with respect to the RH change. The estimated shear strength is about 1.35 GPa, which is comparable to the shear strength for iron oxide at a high pressure of 1.64 GPa.33) Therefore, the friction property is likely to be governed by the direct contact between the tip and sample.

Table II. Estimated parameters by fitting of the frictional property of nanostripe using Eq. (2).

| Relative humidity (%) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

|---|---|---|---|---|---|---|---|---|

| ∣Lc∣ (nN) | 0.04 | 0.05 | 0.07 | 0.06 | 0.07 | 0.05 | 0.06 | 0.05 |

| Fc (nN) | 0.16 | 0.19 | 0.22 | 0.21 | 0.23 | 0.17 | 0.19 | 0.17 |

| τ (GPa) | 1.34 | 1.42 | 1.33 | 1.37 | 1.34 | 1.31 | 1.31 | 1.36 |

| γ (mJ m−2) | 0.45 | 0.53 | 0.71 | 0.62 | 0.8 | 0.5 | 0.60 | 0.48 |

| Ac (nm2) | 0.12 | 0.14 | 0.17 | 0.15 | 0.17 | 0.13 | 0.15 | 0.13 |

Next, we must consider the composition of the nanostripe surface. The frictional property of the nanostripe surface is independent of RH, despite the fact that the nanostripe surface includes Au, whose frictional property is strongly affected by RH. Figure 5 shows the laser microscope image of a nanostripe surface. The image size is 20 × 20 μm2. The cross-section of the surface is overlapped on Fig. 5. The height of the brownish region is lower than that of the white region. Therefore, the brownish and white regions would correspond to Au and Fe, respectively. Here, we estimated the area ratio between Au and Fe by binarizing the microscope image. The area ratio between Au and Fe was approximately 1:2, that is, the area of Fe is twice as large as that of Au. From these results, we considered that the frictional property of nanostripe would be governed by the Fe surface, which is hydrophobic. Therefore, the frictional property of nanostripe was independent of RH. However, the Au area, of which the width was at most 1 μm, would be hydrophilic and water would adsorb on the Au area.

Fig. 5. (Color online) Laser microscope image of a nanostripe surface (20 × 20 μm). Red line shows the cross-section of the image.

Download figure:

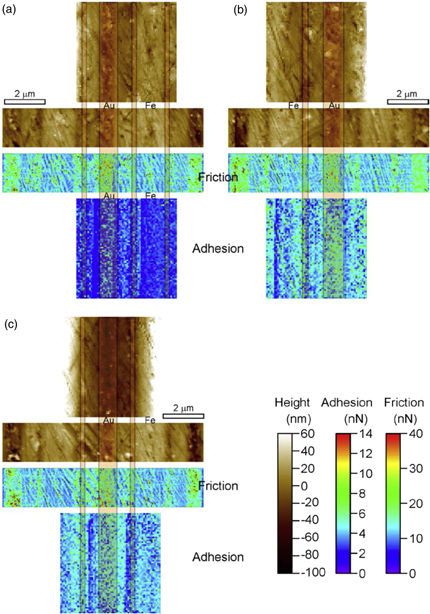

Standard image High-resolution imageFigure 6 shows the comparison between AFM images with friction and adhesion of a nanostripe measured at RH of (a) 10%, (b) 50% and (c) 80%. Adhesion forces were evaluated from a force curve at 64 × 64 points in 5 × 5 μm. Friction measurement was performed in a 10 × 2 μm area. When the RH is low [Fig. 6(a)] or high [Fig. 6(c)], larger adhesion force was observed on and around the Au regions compared with Fe regions. On the other hand, when the RH is about 50% [Figs. 6(c) and 6(d)], at which the adhesion force of Au had a maximum value, there is a minor difference between the adhesion force measured on the Au and Fe regions. Comparing AFM topographic images and adhesion force mappings, the higher adhesion force was observed on the Au regions. Furthermore, comparing friction force and adhesion force, the higher the adhesion force measured, the higher the friction force observed. Figure 7 shows the histograms of the adhesion force of Au (orange), Fe (blue) and nanostripe (black) surfaces measured at RH of (a) 10%, (b) 50% and (c) 80%. When the RH is low [10%; Fig. 7(a)] or high [80%; Fig. 7(c)], the peak distribution of the adhesion force of nanostripe was shifted to a higher value compared with that of Fe. However, when the RH is about 50%, the distribution of the adhesion force of nanostripe was comparable to that of Fe. Considering these results, the adhesion force observed on the Au regions would have some effect on the frictional property of a nanostripe, which differs from that of uniform Fe and Au surfaces. The adhesion force observed on the Au regions of a nanostripe surface was smaller than that observed on Au. Adsorbed water on a nanostripe surface might be smaller than that on a uniform Au surface because the Au area is quite small on a nanostripe surface. Therefore, small adhesion force on Au regions of a nanostripe surface may relate to the fact that when the surface of the water is curved at nanoscale, its surface tension is expected to be smaller than that of a planar interface.24,25) This may lead to the potential for non-linear frictional property with respect to the normal load. Further experiments, concerning issues such as the nanostripe size dependence, are needed to clarify the origin of the frictional property of nanostripe.

Fig. 6. (Color online) Comparison between AFM images with friction and adhesion of a nanostripe measured at RH of (a) 10%, (b) 50% and (c) 80%.

Download figure:

Standard image High-resolution imageFig. 7. (Color online) Histograms of the adhesion force of Au (orange), Fe (blue) and nanostripe (black) surfaces measured at RH of (a) 10%, (b) 50% and (c) 80%.

Download figure:

Standard image High-resolution image4. Conclusions

We have investigated the effect of adhesion force on the frictional property of a nanostripe structure composed of a combination of Au and Fe. In addition, the nanostripe result was compared with that of the Au and Fe surface. The frictional property of the Au surface was significantly affected by humidity. The Au surface was hydrophilic, so the water would be adsorbed on the surface and a large adhesion force was observed. This large adhesion caused by adsorbed water has a large effect on the frictional property of Au, and non-linear dependence of friction force with respect to the normal load was observed. On the other hand, the frictional property of the Fe surface was independent of RH and the friction force was proportional to the normal load. The Fe surface was hydrophobic and the adhesion force of Fe was quite low compared with that of Au. The adhesion force has little effect on the friction forces of Fe, which would be governed by van der Waals interaction between the tip and sample, and linear dependence of the friction force with respect to the normal load was observed. The nanostripe surface showed characteristic frictional property, which differed from that of Au and Fe. The adhesion force of nanostripe was comparable to that of Fe and the frictional property of nanostripe was independent of RH. However, friction force is finite at the normal load of zero and the friction force non-linearly increased with increasing normal load. This might be caused by the composition of the nanostripe surface, which is composed of both Au and Fe.

Acknowledgments

This work was supported by JSPS KAKENHI (Grant Nos. JP25249011 and JP18H03750).