Abstract

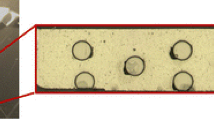

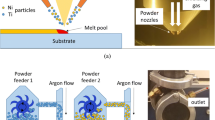

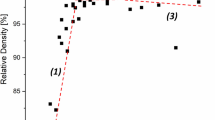

We manufactured NiTi plate-polyimide composite samples and analyzed their thermomechanical behavior. The residual stresses formed in the composite result from the shift of transformation temperatures and shape changes during thermal cycling. We demonstrate the use of finite element analysis for modeling the shape changes. The shape changes result from the difference in coefficients of thermal expansion and from the changes of Young’s modulus and of the coefficient of thermal expansion in the NiTi shape memory alloy.

Similar content being viewed by others

References

O. Ishii, Y. Miyahara, S. Kambe, N. Kutsuzawa, and A. Ishida, Repeatable Shape Memory Effect and Mechanical Resonance of TiNiCu-Coated Magnetic Ribbons, J. Phys. Conf. Ser., 2011, 266, p 012070

K.A. Tsoi, J. Schrooten, Y. Zheng, and R. Stalmans, Part II. Thermomechanical Characteristics of Shape Memory Alloy Composites, Mater. Sci. Eng. A, 2004, 368, p 299–310

L. Heller, D. Vokoun, P. Sittner, and H. Finckh, 3D Flexible NiTi-Braided Elastomer Composites for Smart Structure Applications, Smart Mater. Struct., 2012, 21, p 045016

D. Vokoun, P. Sedlak, M. Frost, J. Pilch, D. Majtas, and P. Sittner, Velcro-Like Fasteners Based on NiTi Micro-Hook Arrays, Smart Mater. Struct., 2011, 20, p 085027

J.J. Gill, D.T. Chang, L.A. Momoda, and G.P. Carman, Manufacturing issues of thin film NiTi microwrapper, Sensors and Actuators A, 2001, 93, p 148–156

A. Ishida and M. Sato, Ti-Ni-Cu Shape-Memory Alloy Thin Film Formed on Polyimide Substrate, Thin Solid Films, 2008, 516, p 7836–7839

W.L. Benard, H. Kahn, A.H. Heuer, and M.A. Huff, Thin-Film Shape-Memory Alloy Actuated Micropumps, J. Microelectromech. Syst., 1998, 7, p 245–251

J.L. Seguin, M. Bendahan, A. Isalgue, V. Esteve-Cano, H. Carchano, and V. Torra, Low Temperature Crystallised Ti-Rich NiTi Shape Memory Alloy Films for Microactuators, Sens. Actuators A, 1999, 74, p 65–69

A. Ishida, Ti-Ni-Cu/Polyimide Composite-Film Actuator and Simulation Tool, Sens. Actuators A, 2015, 222, p 228–236

V.G. Kotnur, F.D. Tichelaar, and G.C.A.M. Janssen, Sputter Deposited Ni-Ti Thin Films on Polyimide Substrate, Surf. Coat. Technol., 2013, 222, p 44–47

V.G. Kotnur, F.D. Tichelaar, W.T. Fu, J.T.M. De Hosson, and G.C.A.M. Janssen, Shape Memory NiTi Thin Films Deposited on Polyimide at Low Temperature, Surf. Coat. Technol., 2014, 258, p 1145–1151

T. Verbiest, D.M. Burland, M.C. Jurich, V.Y. Lee, R.D. Miller, and W. Volksen, Exceptionally Thermally Stable Polyimides for Second-Order Nonlinear Optical Applications, Science, 1995, 268, p 1604–1606

J. de Abajo and J.G. de la Campa, Processable Aromatic Polyimides. Source: Progress in Polyimide Chemistry, Vol 140, Advances in Polymer Science Springer, Berlin, 1999, p 23–59

K. Otsuka and C.M. Wayman, Shape Memory Materials, Cambridge University Press, Cambridge, 1998

S. Numata and T. Miwa, Thermal Expansion Coefficients and Moduli of Uniaxially Stretched Polyimide Films with Rigid and Flexible Molecular Chains, Polymer, 1989, 30, p 1170–1174

Z.D. Wang, X.X. Zhao, S.Q. Jiang, and J.J. Lu, Determining Thermal Expansion Coefficient of Stressed Thin Films at Low Temperature, Polym. Test., 2005, 24, p 839–843

S.X. Lu, P. Cebe, and M. Capel, Thermal Stability and Thermal Expansion Studies of PEEK and Related Polyimides, Polymer, 1996, 37, p 2999–3009

I. Stachiv, D. Vokoun, and Y. Jeng, Measurement of Young’s Modulus and Volumetric Mass Density/Thickness of Ultrathin Films Utilizing Resonant Based Mass Sensors, Appl. Phys. Lett., 2014, 104, p 083102

H.M. Rietveld, A Profile Refinement Method for Nuclear and Magnetic Structures, J. Appl. Cryst., 1969, 2, p 65–71

T.W. Clyne, Residual Stresses in Surface Coatings and Their Effects on Interfacial Debonding, Key Eng. Mater., 1996, 116-117, p 307–330

R.W. Pryor, Multiphysics Modeling Using Comsol: A first Principles Approach, Jones and Bartlett publishers, Sudbury, 2011

Y. Liu, X. Chen, and P.G. McCormick, Effect of Low Temperature Aging on the Transformation Behavior of Near-Equiatomic NiTi, J. Mater. Sci., 1997, 32, p 5979–5984

K.A. Tsoi, R. Stalmans, and J. Schrooten, Transformational Behavior of Constrained Shape Memory Alloys, Acta Mater., 2002, 50, p 3535–3544

Acknowledgment

This work has been supported by the Czech Science Foundation, within projects GA14-15264S and GC15-13174J.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vokoun, D., Sysel, P., Heller, L. et al. NiTi-Polyimide Composites Prepared Using Thermal Imidization Process. J. of Materi Eng and Perform 25, 1993–1999 (2016). https://doi.org/10.1007/s11665-016-2019-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2019-2