Abstract

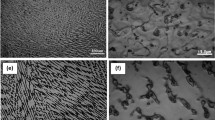

NiTi shape-memory alloys may release poisonous Ni ions at the alloys’ surface. In an attempt to prepare a well-performing surface layer on an NiTi sample, the thermally grown TiO2 layer, which formed during the heat treatment of NiTi, was removed and replaced with a new TiO2 layer prepared using the atomic layer deposition (ALD) method. Using x-ray photoelectron spectroscopy, it was found that the ALD layer prepared at as low a temperature as 100 °C contained Ti in oxidation states + 4 and + 3. As for static corrosion properties of the ALD-coated NiTi samples, they further improved compared to those covered by thermally grown oxide. The corrosion rate of samples with thermally grown oxide was 1.05 × 10−5 mm/year, whereas the corrosion rate of the ALD-coated samples turned out to be about five times lower. However, cracking of the ALD coating occurred at about 1.5% strain during the superelastic mechanical loading in tension taking place via the propagation of a localized martensite band.

Similar content being viewed by others

References

T. Duerig, A. Pelton, and D. Stöckel, An Overview of Nitinol Medical Applications, Mater. Sci. Eng. A, 1999, 273–275, p 149–160

J.V. Humbeeck and R. Stalmans, Thermomechanical Properties of SMA, Shape Memory Materials, K. Otsuka and C.M. Wayman, Ed., Cambridge University Press, Cambridge, 1998,

M. Es-Souni, M. Es-Souni, and H. Fischer-Brandies, Assessing the Biocompatibility of NiTi Shape Memory Alloys Used for Medical Applications, Anal. Bioanal. Chem., 2005, 381, p 557–567

S. Shabalovskaya, G. Rondelli, and M. Rettenmayr, Nitinol Surfaces for Implantation, J. Mater. Eng. Perform., 2009, 18, p 470–474

D.P. Aun, M. Houmard, M. Mermoux, L. Latu-Romain, J.-C. Joud, G. Berthomé, and V.T. Lopes Buono, Development of a Flexible Nanocomposite TiO2 Film as a Protective Coating for Bioapplications of Superelastic NiTi Alloys, Appl. Surf. Sci., 2016, 375, p 42–49

Y. Cheng, W. Cai, H.T. Li, and Y.F. Zheng, Surface Modification on NiTi Alloy with Tantalum to Improve Its Biocompatibility and Radiopacity, J. Mater. Sci., 2006, 41, p 4961

D. Starosvetsky and I. Gotman, Corrosion Behavior of Titanium Nitride Coated Ni–Ti Shape Memory Surgical Alloy, Biomaterials, 2001, 22, p 1853–1859

K.W.K. Yeung, R.W.Y. Poon, X.Y. Liu, J.P.Y. Ho, C.Y. Chung, P.K. Chu, W.W. Lu, D. Chan, and K.M.C. Cheung, Corrosion Resistance, Surface Mechanical Properties, and Cytocompatibility of Plasma Immersion Ion Implantation–Treated Nickel-Titanium Shape Memory Alloys, J. Biomed. Mater. Res. A, 2005, 75, p 256–267

M. Chembath, J.N. Balaraju, and M. Sujata, Surface Characteristics, Corrosion and Bioactivity of Chemically Treated Biomedical Grade NiTi Alloy, Mater. Sci. Eng. C, 2015, 56, p 417–425

T.T. Zhao, Y. Li, Y. Liu, and X.Q. Zhao, Nano-Hardness, Wear Resistance and Pseudoelasticity of Hafnium Implanted NiTi Shape Memory Alloy, J. Mech. Behav. Biomed. Mater., 2012, 13, p 174–184

M. Leskelä and M. Ritala, Atomic Layer Deposition (ALD): From Precursors to Thin Film Structures, Thin Solid Films, 2002, 409, p 138–146

M. Leskelä and M. Ritala, Atomic Layer Deposition Chemistry: Recent Developments and Future Challenges, Angew. Chem. Int. Ed., 2003, 42, p 5548–5554

S.W. Choi, J.Y. Park, and S.S. Kim, Synthesis of SnO2–ZnO Core–Shell Nanofibers Via a Novel Two-Step Process and Their Gas Sensing Properties, Nanotechnology, 2009, 20, p 465603

C.X. Shan, X. Hou, and K.L. Choy, Corrosion Resistance of TiO2 Films Grown on Stainless Steel by Atomic Layer Deposition, Surf. Coat. Technol., 2008, 202, p 2399–2402

A.I. Abdulagatov, Y. Yan, J.R. Cooper, Y. Zhang, Z.M. Gibbs, A.S. Cavanagh, R.G. Yang, Y.C. Lee, and S.M. George, Al2O3 and TiO2 Atomic Layer Deposition on Copper for Water Corrosion Resistance, ACS Appl. Mater. Interfaces., 2011, 3, p 4593–4601

M. Basiaga, M. Staszuk, W. Walke, and Z. Opilski, Mechanical Properties of Atomic Layer Deposition (ALD) TiO2 Layers on Stainless Steel Substrates, Materialwiss. Werkstofftech., 2016, 47, p 512–520

E. Marin, A. Lanzutti, L. Paussa, L. Guzman, and L. Fedrizzi, Long Term Performance of Atomic Layer Deposition Coatings for Corrosion Protection of Stainless Steel, Mater. Corros., 2015, 66, p 907–914

W. Walke, M. Kaczmarek, M. Staszuk, and M. Basiaga, Influence of Purge, Time of Waiting and TiCl4 Dosing Time in a Low-Pressure Atomic Layer Deposition (ALD) Reactor on Properties of TiO2 Layer, Metalurgija, 2017, 56, p 179–181

M.R. Saleem, P. Silfsten, S. Honkanen, and J. Turunen, Thermal Properties of TiO2 Films Grown by Atomic Layer Deposition, Thin Solid Films, 2012, 520, p 5442–5446

C.C. Kei, Y.S. Yu, J. Racek, D. Vokoun, and P. Sittner, Atomic Layer-Deposited Al2O3 Coatings on NiTi Alloy, J. Mater. Eng. Perform, 2014, 23, p 2641–2649

C.C. Kei, Y.H. Yu, J. Racek, D. Vokoun, L. Kadeřávek, Corrosion and Mechanical Properties of Atomic Layer Deposited TiO2 Coatings on NiTi Implants. In 2016 IEEE International Conference Industrial Technology (ICIT) (2016), p 1328–1332

O. Takakuwa and H. Soyama, Effect of Residual Stress on the Corrosion Behavior of Austenitic Stainless Steel, Adv. Chem. Eng. Sci., 2015, 5, p 62–71

X. Zhao, P. Munroe, D. Habibi, and Z. Xie, Roles of Compressive Residual Stress in Enhancing the Corrosion Resistance of Nano Nitride Composite Coatings on Steel, J. Asian Ceram. Soc., 2013, 1, p 86–94

Y.C. Tsui and T.W. Clyne, An Analytical Model for Predicting Residual Stresses in Progressively Deposited Coatings, Thin Solid Films, 1997, 306, p 23–33

R. Karpagavalli, A. Zhou, P. Chellamuthu, and K. Nguyen, Corrosion Behavior and Biocompatibility of Nanostructured TiO2 Film on Ti6Al14V, J. Biomed. Mater. Res. A, 2007, 83, p 1087–1095

C. Trépanier, M. Tabrizian, L. Yahia, L. Bilodear, and D.L. Piron, Effect of Modification of Oxide Layer on NiTi Stent Corrosion Resistance, J. Biomed. Mater. Res. B, 1998, 43, p 433–440

H. Tian, D. Schryvers, D. Liu, Q. Jiang, and J. Van Humbeeck, Stability of Ni in Nitinol Oxide Surfaces, Acta Biomater., 2011, 7, p 892–899

A. Undisz, R. Hanke, K.E. Freiberg, V. Hoffmann, and M. Rettenmayr, The Effect of Heating Rate on the Surface Chemistry of NiTi, Acta Biomater., 2014, 10, p 4919–4923

D. Vokoun, M. Svatuška, J. Olejníček, M. Kohout, J. Drahokoupil, M. Rameš, J. Vejpravová, A. Mantlíková, L. Fekete, J. Kopeček, L. Klimša, and O. Heczko, Ni–TiO2 Nanocomposite Films and Their Magnetic Properties, Physica B Condens. Matter, 2016, 503, p 44–50

J.S. King, E. Graugnard, and C.J. Summers, TiO2 Inverse Opals Fabricated Using Low-Temperature Atomic Layer Deposition, Adv. Mater., 2005, 17, p 1010–1013

D. Chen, E.H. Jordan, M. Gell, and X. Ma, Dense TiO2 Coating Using the Solution Precursor Plasma Spray Process, J. Am. Ceram. Soc., 2008, 91, p 865–872

T. Fu, B.G. Liu, Y.M. Zhou, and X.M. Wu, Sol–gel Titania Coating on NiTi Alloy with a Porous Titania Film as Interlayer, J. Sol Gel. Sci. Technol., 2011, 58, p 307–311

U. Backman, A. Auvinen, and J.K. Jokiniemi, Deposition of Nanostructured Titania Films by Particle-Assisted MOCVD, Surf. Coat. Technol., 2005, 192, p 81–87

H.T. Siu and H.C. Man, Fabrication of Bioactive Titania Coating on Nitinol by Plasma Electrolytic Oxidation, Appl. Surf. Sci., 2013, 274, p 181–187

H. Morawiec, T. Goryczka, J. Lelątko, Z. Lekston, A. Winiarski, E. Rówiński, and F. Stergioudis, Surface Structure of NiTi Alloy Passivated by Autoclaving. Materials Science Forum, vol. 636–637, Trans Tech Publications, Switzerland, 2010, p 971–976

Y.W. Gu, B.Y. Tay, C.S. Lim, and M.S. Yong, Characterization of Bioactive Surface Oxidation Layer on NiTi Alloy, Appl. Surf. Sci., 2005, 252, p 2038–2049

L. Tan and W.C. Crone, Surface Characterization of NiTi Modified by Plasma Source Ion Implantation, Acta Mater., 2002, 50, p 4449–4460

B. Yuan, H. Li, Y. Gao, C.Y. Chung, and M. Zhu, Passivation and Oxygen Ion Implantation Double Surface Treatment on Porous NiTi Shape Memory Alloys and Its Ni Suppression Performance, Surf. Coat. Technol., 2009, 204, p 58–63

Z.D. Cui, H.C. Man, and X.J. Yang, The Corrosion and Nickel Release Behavior of Laser Surface-Melted NiTi Shape Memory Alloy in Hanks, Solution, Surf. Coat. Technol., 2005, 192, p 347–353

C.L. Yaws, Chemical Properties Handbook: Physical, Thermodynamic, Environmental, Transport, Safety, and Health Related Properties for Organic and Inorganic Chemicals, McGraw-Hill, New York, 1999

J.D.P. Counsell, A.J. Roberts, W. Boxford, C. Moffitt, and K. Takahashi, Reduced Preferential Sputtering of TiO2 Using Massive Argon Clusters, J. Surf. Anal., 2014, 20, p 211–215

J. Racek, M. Stora, P. Šittner, L. Heller, J. Kopeček, and M. Petrenec, Monitoring Tensile Fatigue of Superelastic NiTi Wire in Liquids by Electrochemical Potential, Shape Memory Superelasticity, 2015, 1, p 204–230

J.L. Ong, L.C. Lucas, G.N. Raikar, R. Connatser, and J.C. Gregory, Spectroscopic Characterization of Passivated Titanium in a Physiologic Solution, J. Mater. Sci. Mater. Med., 1995, 6, p 113–119

K. Hirmanova, J. Pilch, J. Racek, L. Heller, P. Sittner, and P. Sedlak, Physical Simulation of the Random Failure of Implanted Braided NiTi Stents, J. Mater. Eng. Perform., 2014, 23, p 2650–2658

C.M. Chan, S. Trigwell, and T. Duerig, Oxidation of an NiTi Alloy, Surf. Interface Anal., 1990, 15, p 349–354

Acknowledgments

The work conducted in the Czech Republic and in Taiwan was supported by the Academy of Sciences of the Czech Republic and the Ministry of Science and Technology, R.O.C. within a Czech–Taiwanese Joint Research Project Nos. MOST-15-01 and MOST-17-04. The support of the work of P. Šittner under the Czech Science Foundation via Project AdMat 14-36566G is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vokoun, D., Racek, J., Kadeřávek, L. et al. Atomic Layer-Deposited TiO2 Coatings on NiTi Surface. J. of Materi Eng and Perform 27, 572–579 (2018). https://doi.org/10.1007/s11665-018-3136-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3136-x