Abstract

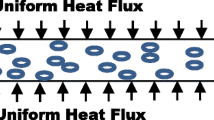

A two region conduction-controlled rewetting model of hot vertical surfaces with internal heat generation and boundary heat flux subjected to constant but different heat transfer coefficient in both wet and dry region is solved by the Heat Balance Integral Method (HBIM). The HBIM yields the temperature field and quench front temperature as a function of various model parameters such as Peclet number, Biot number and internal heat source parameter of the hot surface. Further, the critical (dry out) internal heat source parameter is obtained by setting Peclet number equal to zero, which yields the minimum internal heat source parameter to prevent the hot surface from being rewetted. Using this method, it has been possible to derive a unified relationship for a two-dimensional slab and tube with both internal heat generation and boundary heat flux. The solutions are found to be in good agreement with other analytical results reported in literature.

Similar content being viewed by others

Abbreviations

- A :

-

defined in Eq. (17)

- a :

-

thermal diffusivity \({\hbox{m}^{2}} \mathord{\left/ {\vphantom {{m^{2}} s}} \right. \kern-\nulldelimiterspace} \hbox{s}\)

- Bi i :

-

Biot number \(\frac{{h_{i} \delta}}{K}\) and \(\frac{{h_{i} R_{i}}}{K}\) in one-dimensional and two-dimensional case, respectively (i = 1, 2)

- C :

-

specific heat (J/kg °C)

- HBIM:

-

heat balance integral method

- h i :

-

heat transfer coefficient (W/m2 °C)

- j 1, j 2 :

-

defined in Eq. (15)

- K :

-

thermal conductivity (W/m °C)

- L :

-

length scale (m)

- Ms i , Mt i :

-

effective Biot number in two-dimensional slab and tube respectively (i = 1, 2)

- Pe :

-

dimensionless wet front velocity \(\frac{{\rho Cu\delta}}{K}\) and \(\frac{{\rho CuR_{2}}}{K}\) for one- dimensional and two-dimensional case, respectively

- Q :

-

dimensionless internal heat source parameter defined in Eq. (3)

- Q cri :

-

critical internal heat source parameter

- q :

-

boundary heat flux (W/m2)

- \({\bar{q}}\) :

-

internal heat generation, W/m3

- R i :

-

radius(i = 1, 2), m

- T :

-

temperature (°C)

- T 0 :

-

wet front temperature that corresponds to the temperature at the minimum film boiling heat flux (°C)

- T S :

-

saturation temperature (°C)

- T W :

-

initial temperature of the dry surface (°C)

- t:

-

time (s)

- u :

-

wet front velocity (m/s)

- \({\bar{x}}, {\bar{y}}, {\bar{r}}\) :

-

length coordinates (m)

- x,y,r :

-

dimensionless length coordinates

- α, β, γ :

-

constants defined in text

- λ :

-

defined in Eq. (15)

- δ :

-

wall thickness (m)

- θ :

-

non-dimensional temperature defined in Eq. (3)

- θ 1 :

-

non-dimensional temperature parameter defined in Eq. (3)

- \({\bar{\theta}}\) :

-

non-dimensional temperature integral defined in Eq. (9)

- θ i :

-

non-dimensional surface temperature

- ρ :

-

density (kg/m3)

- ɛ :

-

radius ratio defined in Eq. (3)

- ψ, ξ 1,ξ2 :

-

defined in Eq. (18)

- 0:

-

quench front

- l:

-

liquid side

- v:

-

dry side

- +:

-

evaluated at an infinitesimal increment of distance

- −:

-

evaluated at an infinitesimal increment of distance

- 1, 2:

-

for wet and dry region, respectively

References

Yamanouchi A (1968) Effect of core spray cooling in transient state after loss of coolant accident. J Nucl Sci Tech 5:547–558

Sun KH, Dix GE, Tien CL (1974) Effect of precursory cooling on falling-film rewetting. ASME J Heat Transf 97:360–365

Duffey RB, Porthouse DTC (1973) The physics of rewetting in water reactor emergency core cooling. Nucl Eng Des 25:379–394

Duffey RB, Porthouse DTC (1972) Experiments on the cooling of high temperature surfaces by water jets and drops. Report No.RD/B/N2386, Berkeley Nuclear Laboratories

Dua SS, Tien CL (1978)An experimental investigation of falling-film rewetting. Int J Heat Mass Transf 21:955–965

Yeh HC (1975) An analysis of rewetting of a nuclear fuel rod in water reactor emergency core cooling. Nucl Eng Des 34:317–322

Tien CL, Yao LS (1975) Analysis of conduction-controlled rewetting of a vertical surface. ASME J Heat Transf 97:161–165

Satapathy AK, Kar PK (2000) Rewetting of an infinite slab with boundary heat flux. Numer Heat Transf A 37:87–99

Satapathy AK, Sahoo RK (2002) Rewetting of an infinite slab with uniform heating under quasi-steady conditions. ASME J Heat Transf 124:875–880

Olek S, Zvirin Y, Elias E (1988) Rewetting of hot surfaces by falling liquid films as a conjugate heat transfer problem. Int J Multiphase Flow 14:13–33

Dorfman A (2004) Transient heat transfer between a semi infinite hot plate and a flowing cooling liquid film. ASME J Heat Transf 126:149–154

Peng XF, Peterson GP (1992) Analysis of Rewetting for surface tension induced flow. ASME J Heat Transf 114:703–707

Sawan M, Zaki G, Temraz H (1978) Analysis of rewetting of hot cladding surfaces with heat generation. Arab J Nucl Sci Appl 11:237–259

Yao LS (1976) Rewetting of a vertical surface with internal heat generation. AIChE Symp Ser Solar Nucl Heat Transf 73:46–50

Duffey RB, Hughes ED (1991) Dry out stability and inception at low flow rates. Int J Heat Mass Transf 34:473–481

Chan SH, Zhang W (1994) Rewetting theory and the dryout heat flux of smooth and grooved plates with uniform heating. ASME J Heat Transf 116:173–179

Goodman TR (1958) The heat balance integral and its application to problems involving a change of phase. ASME J Heat Transf 80:335–342

Arpaci VS (1966) Conduction heat transfer, Addison-Wesley Publishing Company, Reading

Eckert ERG, Drake RM (1959) Heat and mass transfer, 2nd edn. McGraw Hill, New York

Schlichting H (1968) Boundary layer theory, 6th edn. McGraw Hill, New York

Sfeir AA (1976) the heat balance integral in steady-state conduction. ASME J Heat Transf 98:466–470

Burmeister LC (1979) Triangular fin performance by the heat balance integral method. ASME J Heat Transf 101:562–564

Sahu SK, Das PK, Bhattacharyya S (2006) A comprehensive analysis of conduction-controlled rewetting of hot surfaces by the heat balance integral method. Int J Heat Mass Transf 49:4978–4986

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahu, S.K., Das, P.K. & Bhattacharyya, S. Rewetting analysis of hot surfaces with internal heat source by the heat balance integral method. Heat Mass Transfer 44, 1247–1256 (2008). https://doi.org/10.1007/s00231-007-0360-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-007-0360-6