Abstract

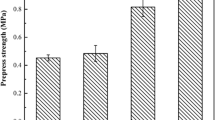

A full-factorial experimental design was used to investigate the effects of three factors on UF resin efficiency. Within the limits of this study, the three factors, namely, resin content loss, resin coverage level and resin pre-cure time for mechanical blended MDF fibres were found to have significant effects on resin efficiency as evaluated by the internal bond strength (IB) of the panels. The most significant factor was resin content loss followed by resin coverage level and resin pre-cure. The resin coverage level had a positive effect on resin efficiency, while the resin content loss, resin pre-cure time at 40 °C conditions, the interactions of resin coverage level and resin content loss as well as resin coverage level with pre-cure had negative effects on resin efficiency. For a given resin content, the resin efficiency could be increased by 35% by increasing the level of resin coverage. The resin efficiency obviously decreased with resin content loss and pre-cure time.

Zusammenfassung

In einem vollständig faktoriell angelegten Versuch wurde die Wirkung der drei Faktoren Harzverlust, Harzverteilungsgrad und Harzvorhärtung auf die UF-Harzwirksamkeit untersucht. Im Rahmen dieser Studie zeigte sich anhand der Bewertung der Querzugfestigkeit (IB) der Platten, dass sich diese drei Faktoren erheblich auf die Harzwirksamkeit bei mechanisch durchmischten MDF-Fasern auswirken. Der bedeutendste Faktor war Harzverlust gefolgt von Harzverteilungsgrad und Harzvorhärtung. Der Harzverteilungsgrad wirkte sich auf die Harzwirksamkeit positiv aus. Dagegen wirkten sich Harzverlust, Harzvorhärtungszeit bei einer Temperatur von 40 °C, sowie die gemischten Glieder aus Harzverteilungsgrad und Harzverlust sowie aus Harzverteilungsgrad und Vorhärtung negativ auf die Harzwirksamkeit aus. Durch eine verbesserte Harzverteilung konnte die Harzwirksamkeit bei gegebenem Harzgehalt um 35% erhöht werden. Die Harzwirksamkeit nimmt offensichtlich mit zunehmendem Harzverlust und Vorhärtungszeit ab.

Similar content being viewed by others

References

America Society for Testing and Materials (1999) Standard methods of evaluating the properties of wood based fibre and particle panel materials. ASTM Standard Designation: D-1037-99

Anonymous (2003) Chinese tiger wide awake. Wood Based Panels Intern 23(3):11–20

Bücking G (1982) Resin blending of MDF fibre. In: Proceedings of the 16th Particleboard/Composite Materials Symposium. Washington State University, Pullman, WS, USA, pp 269–276

Dunky M (1998) Urea-formaldehyde (UF) adhesive resins for wood. Int J Adhes Adhes 18:95–107

Gran G (1982) Blowline blending in dry process fibreboard production. In: Proceedings of the 16th Particleboard/Composite Materials Symposium. Washington State University, Pullman, WS, USA, pp 245–259

Loxton C, Hague J (1996) Resin blending in the MDF industry – Can it be improved? In: Proceedings of the 3rd Pacific Rim Bio-Based Composite Symposium. December 2–5, Kyoto, Japan, pp 392–400

Robson D (1991) What happens with blending in the MDF blowline. In: Proceedings of the 25th Particleboard/Composite Materials Symposium. Washington State University, Pullman, WS, USA, pp 167–179

Waters GD (1990) Medium density fibreboard blow line blending-theories in and around the black box. In: Proceeding of NPA Resin and Blending Seminar. National Particleboard Assocation, Gaitherburg, MD, USA, pp 56–61

Xing C (2003) Characterization of urea formaldehyde resin efficiency affected by four factors in the manufacture of medium density fiberboard. PhD thesis, Laval University, Canada

Riedl B, Cloutier A, Xing C, Shaler SM (2003) Characterization of urea-formaldehyde distribution on medium density fiberboard fibers by laser fluorescence Microscopy. In: Proceedings of the IAWPS 2003, pp 321–324

Xing C, Riedl B, Cloutier A (2004) Measurement of urea-formaldehyde resin distribution as a function of MDF fiber size by laser scanning microscopy. Wood Sci Technol 37(6):495–507

Xing C, Riedl B, Cloutier A, Shaler SM (2005) Characterization of UF resin penetration into MDF fibers. Wood Sci Technol 39(5):374–384

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, C., Deng, J., Zhang, S. et al. UF resin efficiency of MDF as affected by resin content loss, coverage level and pre-cure. Holz Roh Werkst 64, 221–226 (2006). https://doi.org/10.1007/s00107-006-0101-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-006-0101-4