Summary

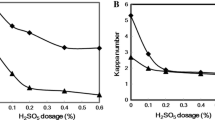

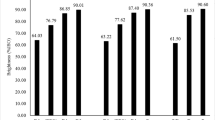

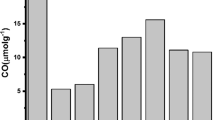

Some aspects of sulphur-free soda pulping with anthraquinone (AQ) additions and chlorine-free bleaching with oxygen-based treatments were investigated with the aim of producing bleached softwood pulp with kraft-like strength properties. The extent of soda-AQ pulping was studied by pulping to 32, 42 and 68 Kappa number. After oxygen delignification to 10, 15 and 20 Kappa number respectively, the extent of bleaching with ozone, alkali extraction, and hydrogen peroxide treatments (ZEP sequence) was studied. For comparison, oxygen delignified pulps were conventionally bleached with a sequential chlorine/chlorine dioxide, alkali extraction, and chlorine dioxide (D/CED) sequence. A reference kraft pulp at 45 Kappa number was similarly oxygen delignified and bleached.

Kraft-like strength properties (as measured by tear/burst relationships) were attainable if soda-AQ pulping was terminated at high Kappa number and was followed by oxygen delignification and D/CED bleaching. This pulp had a 3% (on wood) higher total yield and consumed less active alkali (2.0% as Na2O) than the bleached reference kraft pulp.

Soda-AQ pulping followed by oxygen delignification and ZEP bleaching produced pulp with strength properties that were at least 25% less than those of the reference kraft pulp after oxygen delignification and conventional bleaching with chlorine-based treatments. Although the combination soda-AQ pulping to low Kappa number and extended oxygen delignification adversely affected pulp strength properties, it was ZEP bleaching and ozone treatments in particular, which caused the majority of the strength loss.

Similar content being viewed by others

References

Allison, R. W. 1981: Extended oxygen delignification of alkaline pulps from Pinus radiata. New Zealand J. For. Sci. 11:287–297

Allison, R. W. 1982a. Bleaching of alkaline pulps from Pinus radiata. New Zealand J. For. Sci. 12:107–119

Allison, R. W. 1982b: Efficient ozone and peroxide bleaching of alkaline pulps from Pinus radiata. Appita 36:42–46

Allison, R. W. 1982c: Data to be published

Almberg, L; Croon, I.; Jamieson, A. 1979: Oxygen delignification as part of future mill systems. Tappi 62 (6): 33–35

Fossum, D.; Hagglund, S.; Lindqvist, B. 1980: Alkaline pulping of pine and birch with anthraquinone as additive, Part 2. Svensk Papperstidn. 83: 455–460

Fullerton, T. J.; Kerr, A. J. 1981: Practical aspects of kraft-AQ pulping of Pinus radiata. Appita 35: 135–139

Holton, H. 1977: Soda additive softwood pulping: a major new process. Pulp Paper Mag. Can. 78: T218-T223

Kindron, R. 1978: Practical application of hydrogen peroxide for bleaching chemical pulps. Oxygen, Ozone and Peroxide Pulping and Bleaching Seminar, New Orleans

Liebergott, N.; van Lierop, B. 1978: The use of ozone in bleaching and brightening wood pulps. Oxygen, Ozone and Peroxide Pulping and Bleaching Seminar. New Orleans

MacLeod, M. 1980: Comparing pulp strengths: do's and dont's. 66th Annual Meeting of CPPA, Montreal

Malinen, R. 1980: Techno-economic evaluation of using anthraquinone in different mill alternatives. TAPPI Pulping Conference, Atlanta

Perkins, J. 1978. Ozone bleaching has potential for closing pulp mill water systems. Pulp and Paper 52 (7): 76–78

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Allison, R.W. Production of bleached softwood pulp by low pollution processes. Wood Sci.Technol. 17, 129–137 (1983). https://doi.org/10.1007/BF00369130

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369130