Abstract

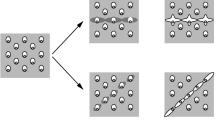

A model originally developed to simulate crack propagation in structural steel has been evaluated for porous compacted specimens of aspirin. The fracture mechanism is assumed to consist of hole growth and coalescence. The program allows both visualization of crack growth and the calculation of crack velocity. Simulations to investigate the effect of stress intensity factor indicate that the critical stress intensity factor for sustained growth for aspirin is of the order of 0.15 MPa m1/2 consistent with experimental findings. The program is easy to use enabling many simulations to be performed with minimum effort.

Similar content being viewed by others

Abbreviations

- a :

-

Polar coordinate with origin at the crack tip

- C d :

-

Propagation velocity of the irrotational wave

- E :

-

Young's modulus of elasticity

- H :

-

Indentation hardness

- K :

-

Stress intensity factor at the crack tip

- K IC :

-

Critical stress intensity factor

- n :

-

The exponent

- R :

-

Radius of the hole/pore

- t :

-

Time

- V :

-

Crack-tip velocity

- β:

-

Fluidity (i.e. the reciprocal of the viscosity)

- δ:

-

The smoothening length

- θ:

-

Polar coordinate with origin at the crack tip

- ϱ:

-

True density

- σ:

-

Stress

- σ0 :

-

Flow or yield stress

- ν:

-

Poisson's ratio

References

A. B. Mashadi and J. M. Newton, J. Pharm. Pharmacol. 39 (1987) 961.

R. J. Roberts and R. C. Rowe, Int. J. Pharm. 52 (1989) 213.

P. York, F. Bassam, R. C. Rowe and R. J. Roberts, ibid. 66 (1990) 143.

R. J. Roberts, R. C. Rowe and P. York, ibid. (1992) in press.

A. B. Mashadi and J. M. Newton, J. Pharm. Pharmacol. 40 (1988) Suppl. 120 p.

K. B. Broberg in Advances in Constitutive Laws for Engineering Materials, edited by F. Jinghong and S. Murakami, Vol. 1, Pergamon, Oxford, 1989 pp. 255–358.

K. B. Broberg, Int. J. Fract. 42 (1990) 277.

R. C. Rowe and R. J. Roberts, Powder Technol. submitted.

K. B. Broberg, personal communication (1990).

H. Gucluyildiz, G. S. Banker and G. E. Peck, J. Pharm. Sci. 66 (1977) 407.

K. Ridgway, E. Shotten and J. Geasby, J. Pharm. Pharmacol. 21 (1969) Suppl. 19S.

R. J. Roberts, R. C. Rowe and P. York, Powder Technol. 65 (1991) 139.

K. Ridgway, M. E. Aulton and P. H. Rosser, J. Pharm. Pharmacol. 22 (1970) 70S.

R. C. Rowe and R. J. Roberts, Int. J. Pharm. 78 (1992a) 49.

Idem, ibid. 86 (1992) 49.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rowe, R.C., Roberts, R.J. Simulation of crack propagation in porous compacted specimens of aspirin. JOURNAL OF MATERIALS SCIENCE 28, 3385–3390 (1993). https://doi.org/10.1007/BF00354262

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00354262