Abstract

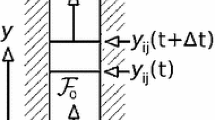

The present work is concerned with the mathematical modelling and numerical simulation of three-dimensional (3-D) bicomponent extrusion. The objective is to provide an understanding of the flow phenomena involved and to investigate their impact on the free surface shape and interface configuration of the extruded article. A finite element algorithm for the 3-D numerical simulation of bicomponent stratified free surface flows is described. The presence of multiple free surfaces (layer interface and external free surfaces) requires special free surface update schemes. The pressure and viscous stress discontinuity due to viscosity mismatch at the interface between the two stratified components is handled with both a double node (u−v−w−P 1 −P 2 −h 1 −h 2) formulation and a penalty function (u−v−w−P−h 1 −h 2) formulation.

The experimentally observed tendency of the less viscous layer to encapsulate the more viscous layer in stratified bicomponent flows of side-by-side configuration is established with the aid of a fully 3-D analysis in agreement with experimental evidence. The direction and degree of encapsulation depend directly on the viscosity ratio of the two melts. For shear thinning melts exhibiting a viscosity crossover point, it is demonstrated that interface curvature reversal may occur if the shearing level is such that the crossover point is exceeded. Extrudate bending and distortion of the bicomponent system because of the viscosity mismatch is shown. For flows in a sheath-core configuration it is shown that the viscosity ratio may have a severe effect on the swelling ratio of the bicomponent system.

Modelling of the die section showed that the boundary condition imposed at the fluid/fluid/wall contact point is critical to the accuracy of the overall solution.

Similar content being viewed by others

References

Southern JH, Ballman RL (1973) Applied Polymer Science 20:175–189

Southern JH, Ballman RL (1975) J Polym Sci 13:863–869

Everage AE (1975) Trans Soc Rheol 19:509

Han CD (1981) Multiphase Flow in Polymer Processing. Academic Press, New York

Lee BL, White JL (1974) Trans Soc Rheol 18:467–492

Mavridis H, Hrymak AN, Vlachopoulos J (1987) AIChE J 33:410

White JL, Ufford RC, Dharod KR, Price RL (1972) J Appl Pol Sci 16:1313

Khan AA, Han CD (1977) Trans Soc Rheol 21:101

Pool H (1987) Paper presented at the extruder-Future Symposium, Enschede, The Netherlands, August 1987

Mitsoulis E (1986) J Rheol 30 (S):S23

Mitsoulis E, Heng FL (1987) J Appl Pol Sci 34:1713–1725

Dheur J, Crochet MJ (1987) Rheol Acta 26:401–413

Binding DM, Walters K, Dheur J, Crochet MJ (1987) Phil Trans R Soc Lond A323:424–469

Dheur J, Crochet MJ (1989) J Non-Newt Fluid Mech 32:1–18

Joseph DD, Renardy M, Renardy Y (1984) J Fluid Mech 141:309

Than PT, Rosso F, Joseph DD (1987) Int J Eng Sci 25:189

Karagiannis A, Mavridis H, Hrymak AN, Vlachopoulos J (1988) Polym Eng Sci 28:982–988

Karagiannis A (1989) Modelling of Single Component and Bicomponent Extrusion Flows. PhD Thesis, McMaster University, Hamilton, Ontario, Canada

White JL, Lee BL (1975) Trans Soc Rheol 19:457–479

Tadmor Z, Gogos CG (1979) Principles of Polymer Processing. John Wiley & Sons, New York

Karagiannis A, Hrymak AN, Vlachopoulos J (1989) Rheol Acta 28:121–133

Huebner KH, Thornton EA (1982) The Finite Element Method for Engineers, 2nd Ed. Wiley, New York

Dhatt G, Touzot G (1984) The Finite Element Method Displayed. Wiley, New York

Kheshgi HS, Scriven LE (1985) Int J Num Meth Fluids 5:785–803

Kistler SF (1984) The Fluid Mechanics of Curtain Coatings and Related Viscous Free Surface Flows with Contact Lines. PhD Thesis, Univ Minnesota, Minneapolis

Tran-Cong T, Phan-Thien N (1988) Rheol Acta 27:21–30

Shiojima T, Shimazaki Y (1987) In: Pande GN, Middleton J (eds) Proceedings of the NUMETA '87, Vol 3. Martinus Nijhoff Publishers, Swansea

Karagiannis A, Mavridis H, Hrymak AN, Vlachopoulos J (1988) Int J Num Meth Fluids 8:123–138

Reitemeyer PT (1988) Kunststoffe 78:395–397

Minagawa N, White JL (1975) Pol Eng Sci 15:825

Phuoc HB, Tanner RI (1980) J Fluid Mech 98:253–271

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Karagiannis, A., Hrymak, A.N. & Vlachopoulos, J. Three-dimensional studies on bicomponent extrusion. Rheol Acta 29, 71–87 (1990). https://doi.org/10.1007/BF01331802

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01331802