Abstract

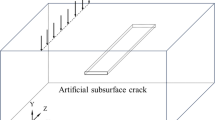

An ultrasonic inspection method is used to obtain the circumference of a subsurface hole and the depth of the hole below the surface. A pitch-catch Rayleigh wave transducer set-up was used to launch a Rayleigh surface wave at the flaw and to capture and record the scattered waves. The frequency spectrum of the scattered waves can be used to obtain the depth of the hole. The ligament of material between the hole and the surface is sent into resonance, and this feature can be extracted from the scattered waves' frequency spectrum. The frequency is a function of the ligament length; thus the hole depth can be obtained. The circumference of the hole is found from a time of flight measurement. A Rayleigh wave is formed that travels around the hole's surface. The length of time required for the wave to travel around the hole is a measure of the circumference.

Similar content being viewed by others

References

R. E. Peterson,Stress Concentration Factors (John Wiley & Sons, New York, 1974).

L. W. Zachary and B. J. Skillings, Displacement discontinuity method applied to nondestructive testing related stress problems,Int. J. Numer. Methods Eng. 18:1231–1244 (1982).

M. G. Silk, The determination of crack penetration using surface waves,NDT Int. 9:290–297 (1976).

M. G. Silk, Sizing crack-like defects by ultrasonic means, inResearch Techniques in Non-Destructive Testing, R. S. Sharpe, ed. (Academic Press, London, 1977).

K. G. Hall, Crack depth measurement in rail steel by Rayleigh visualization,Non-Destr. Testing 9:121–126 (1976).

L. W. Zachary, C. P. Burger, L. W. Schmerr, and A. Singh, Surface crack characterization by use of dynamic photoelastic spectroscopy,Exp. Mech., to be published.

A. Singh, C. P. Burger, L. W. Schmerr, L. W. Zachary, Dynamic photoelasticity as an aid to sizing surface cracks by frequency analysis, inMechanics of Nondestructive Testing, W. W. Stinchcomb, ed., (Plenum, New York, 1980).

C. P. Burger and A. Singh, An ultrasonic technique for sizing surface cracks, Proc. DARPA/AFWAL Review of Progress in Quantitative NDE, AFWAL-TR-81-4080, 436–442 (1981).

C. P. Burger, A. J. Testa, and A. Singh, Dynamic photoelasticity as an aid in developing new ultrasonic test methods,Exp. Mech.,22:147–154 (1982).

C. P. Burger and A. J. Testa, Rayleigh wave spectroscopy to measure the depth of surface cracks,Proc. 13th Symp. on Non-Destructive Evaluation 9–18, B. E. Leornard, ed., (NTIAC, Southwest Research Inst., San Antonio, 1981).

C. P. Burger, A. J. Testa, and A. Singh, Photoelastic visualization in the development of quantitative ultrasonics, Elastic Wave Scattering and Propagation, 197–206, V. K. Varadan and V. V. Varodan, Ed., (Ann Arbor Science, Mich., 1982).

L. L. Morgan, The spectroscopic determination of surface topography using acoustic surface waves,Acoustica 30:222–228 (1974).

L. J. Bond, Finite difference methods applied to ultrasonic nondestructive testing, Proc. of ARPA/AFML Review of Progress in Quantitative NDE, La Jolla, Calif. (July 1979).

B. Q. Vu and V. K. Kinra, Diffraction of Rayleigh waves in a half-space, University of Colorado Report CUMER-81-7 (Aug. 1981).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zachary, L.W. Quantitative use of Rayleigh waves to locate and size subsurface holes. J Nondestruct Eval 3, 55–63 (1982). https://doi.org/10.1007/BF00566955

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00566955