Abstract

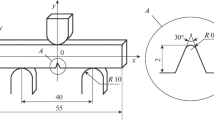

Fatigue crack closure has been directly observed in polymethyl methacrylate and the topography of the fracture surface features studied by interferometry. The mating fatigue striations were observed to meet ridge to groove. Thus the fatigue crack had advanced cycle by cycle deviating away from and back to the general fracture plane in an undulatory fashion. The offset distance was considerably greater than the permanent opening displacement of the crack tip, and crack advancement was essentially brittle in nature. A simple biharmonic loading programme has been used and the low frequency (mean stress change) also introduced its own longer wavelength undulations on the fracture surface. Observations on aluminium alloy indicate similar behaviour.

Similar content being viewed by others

References

G. Jacoby, AGARD Report No. 541.

P. J. E. Forsyth, Int. J. Fatigue January (1983).

M. J. McGuigan, NACA TN 3190 (1954).

P. J. E. Forsyth and P. M. Powell, (in press).

P. J. E. Forsyth, Met. Technol. October (1978) 351.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Forsyth, P.J.E. Fatigue crack closure and its dependence on fracture features. J Mater Sci 19, 1836–1850 (1984). https://doi.org/10.1007/BF00550254

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00550254