Abstract

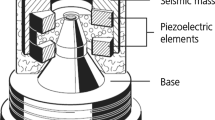

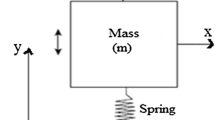

The choice of piezoelectric material for a mechanical resonator sensor development is essential in terms of sensitivity, compatibility with the environment in which it will operate (high temperatures, environment acidity, …), complexity of the manufacturing processes implemented and costs involved. In this paper, piezoelectric detection is studied to understand mechanical resonator sensor operation principle and express it into a mathematical model. Validation by simulation tests of the developed model of measurement accuracy and measurement error as a function of relative vibration movement is performed. Applying this model, sensor characteristics and performance will be improved therefore, a new mechanical resonator sensor design can be proposed. The aim of these improvements is to obtain more accurate results and provide accurate information on vibratory level. A comparative study is conducted to show the effectiveness of the obtained results compared to the literature. These results have also demonstrated that a suitable and appropriate choice of damping rate improve the accelerometer operation and enhances the vibratory analysis technique.

Similar content being viewed by others

References

Breneur, C. (2002). Eléments de maintenance préventive des machines tournantes dans le cas de défauts combinés d’engrenages et de roulements. PhD Thesis from the National Institute of Applied Sciences of Lyon (France).

Tomache, A. (2001). Communication SME-ERCE, Symposium sur la maintenance industrielle. AEID-IAP. Algiers, January, 21: 23, 2001.

Medeiros, K. A. R., Barbosa, C. R. H., & de Oliveira, E. C. (2015). Flow measurement by piezoelectric accelerometers: Application in the oil industry. Petroleum Science and Technology, 33(13–14), 1402–1409.

Yu, J.-C., & Lai, F.-H. (2011). Design and fabrication of the micro-accelerometer using piezoelectric thin films. Ferroelectrics, 263(1), 101–106.

Lumentut, M. F., Teh, K. K., & Howard, I. (2015). Computational FEA model of a coupled piezoelectric sensor and plate structure for energy harvesting. Australian Journal of Mechanical Engineering, 5(2), 199–208.

Hewa-Kasakarage, N. N., Kim, D., Kuntzman, M. L., & Hall, N. A. (2013). Micromachined piezoelectric accelerometers via epitaxial silicon cantilevers and bulk silicon proof masses. Journal of Microelectromechanical Systems, 22(6), 1438–1446.

Lv, H., Qin, L., & Liu, J. (2015). Principle research on a single mass six-degree-of freedom accelerometer with six groups of piezoelectric sensing elements. IEEE Sensors Journal, 15(6), 3301–3309.

Han, R.-H., Wang, J.-Y., Xu, M.-H., & Guo, H. (2016). Design of a tri-axial micro piezoelectric accelerometer. In 2016 Symposium on piezoelectricity, acoustic waves, and device applications, 21–24 Oct, 2016, Xi’an, Shaanxi, CHINA

Xu, M.-H., Wang, J.-Y., Han, R.-H., Zhou, H., & Guo, H. (2016). Analytical and finite element analysis of a new Tri-axial piezoelectric accelerometer. In 2016 Symposium on piezoelectricity, acoustic waves, and device applications, Oct. 21–24, 2016, Xi’an, Shaanxi, CHINA.

Yin, S., Niu, G., Vilquin, B., Gautier, B., Le Rhun, G., Defaÿ, E., & Robach, Y. (2012). Epitaxial growth and electrical measurement of single crystalline Pb(Zr0.52Ti0.48)O3 thin film on Si(001) for micro-electromechanical systems. Thin Solid Films, 520(14), 4572–4575.

Lebrun, A. (2011). Modélisation et conception d’un capteur de vibrations à fibre optique par analyse polarimétrie : application à la sismologie. PhD Thesis, Institute of Solid State Electronics and Systems, University of Strasbourg, France.

Hu, J., Peng, H., Liu, T., Yao, X., Wu, H., & Lu, P. (2019). A flow sensing method of power spectrum based on piezoelectric effect and vortex-induced vibrations. Measurement, 131, 473–481.

Loghmani, A., Danesh, M., & Keshmiri, M. (2016). Modal structural acoustic sensing with minimum number of optimally placed piezoelectric sensors. Journal of Sound and Vibration, 363, 345–358.

Bajri, A., & Høgsberg, J. (2018). Identification of damping and complex modes in structural vibrations. Journal of Sound and Vibration, 431, 367–389.

Korobiichuk, I. (2016). Mathematical model of precision sensor for an automatic weapons stabilizer system. Measurement, 89, 151–158.

Mei, B., Lucas, J., Holé, S., Lamarque, I., & Cheronb, N. (2016). Origin of frequency difference between damped and sustained modes in vibrating wire sensors. Sensors and Actuators A, 241, 66–73.

Richardot T. (2016). Développement d’un matériau piézoélectrique sans plomb pour la réalisation de sondes ultrasonores haute fréquence. Thèse de doctorat en Chimie des matériaux, université François-Rabelais de Tours, 2016, France.

Eidi, A., Ghavifekr, H. B., & Shamsi, M. (2019). A novel biosensor based on micromechanical resonator array for lab-on-a-chip applications. Sensing and Imaging. https://doi.org/10.1007/s11220-019-0261-z

Xu, M.-H., et al. (2017). Noise analysis of the triaxial piezoelectric micro-accelerometer. In 2017 Symposium on piezoelectricity, acoustic waves, and device applications, Oct. 27–30, 2017, Chengdu, Sichuan, China.

Lee, J.-M., et al. (2016). High-shock silicon accelerometer with a plate spring. International Journal of Precision Engineering and Manufacturing, 17(5), 637–644.

Kong, L.-F., et al. (2017). Performance improvement of CTGS and YCOB crystals for high temperature piezoelectric accelerometer applications. In 2017 Symposium on piezoelectricity, acoustic waves, and device applications, Oct. 27–30, 2017, Chengdu, Sichuan, China.

Kim, M.-G., et al. (2018). MEMS PZT oscillating platform for fine dust particle removal at resonance. International Journal of Precision Engineering and Manufacturing, 19(12), 1851–1859.

Fu, X., & Liao, W.-H. (2018). Nondimensional model and parametric studies of impact piezoelectric energy harvesting with dissipation. Journal of Sound and Vibration, 429, 78–95.

Zhao, S., & Fu, H. (2018). A novel vibration sensor system for frequency measurement based on Bias Flip technique. Measurement, 124, 56–63.

Ghemari, Z. (2018). Progression of the vibratory analysis technique by improving the piezoelectric sensor measurement accuracy. Microwave and Optical Technology Letters. https://doi.org/10.1002/mop.31436

Ghemari, Z., & Saad, S. (2019). Enhancement of capacitive accelerometer operation by parameters improvement. International Journal of Numerical Modelling Electronic Networks Devices and Fields, 32(22), e2568. https://doi.org/10.1002/jnm.2568

Ghemari, Z., & Saad, S. (2019). The use of mechanical sensitivity model to enhance capacitive sensor characteristics. Analog Integrated Circuits and Signal Processing. https://doi.org/10.1007/s10470-018-01383-w

Reguieg, S. K., Ghemari, Z., Benslimane, T., & Saad, S. (2019). Modeling and Enhancement of Piezoelectric Accelerometer Relative Sensitivity. Sensing and Imaging an International Journal. https://doi.org/10.1007/s11220-018-0222-y

Acknowledgements

The authors thank Prof. Salah Saad for his help in improving this article and and they also thank the Algerian general direction of research (DGRSDT) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghemari, Z., Belkhiri, S. Mechanical Resonator Sensor Characteristics Development for Precise Vibratory Analysis. Sens Imaging 22, 40 (2021). https://doi.org/10.1007/s11220-021-00361-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11220-021-00361-3