Abstract

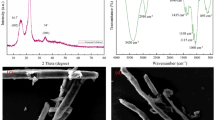

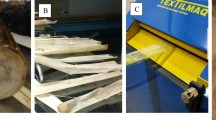

Cellulose, obtained both from sugarcane bagasse and mango seeds, was used for synthesizing cellulose acetate in order to produce asymmetric membranes. These were compared to membranes of commercial cellulose acetate (Rhodia). All produced membranes were asymmetric, characterized by the presence of a dense skin and a porous support. Differences regarding the morphology of the surfaces as well as of the porous support can be noticed. Scanning Electron Microscopy (SEM) showed that the morphology of the superficial layer, responsible for transport, depends on the different lignin content of the starting material and also on the viscosity average molecular weight of the cellulose acetates produced from sugarcane bagasse, mango seed, and Rhodia’s commercial cellulose acetate.

Similar content being viewed by others

References

Cerqueira DA, Rodrigues Filho G, Meireles CD (2007) Optimization of sugarcane bagasse cellulose acetylation. Carbohydr Polym 69(3):579–582

Cerqueira DA, Rodrigues G, Assuncao RMN (2006) A new value for the heat of fusion of a perfect crystal of cellulose acetate. Polym Bull 56(4–5):475–484

Meireles CDS, Rodrigues Filho G, de Assuncao RMN, Zeni M, Mello K (2007) Blend compatibility of waste materials—cellulose acetate (from sugarcane bagasse) with polystyrene (from plastic cups): diffusion of water, FTIR, DSC, TGA, and SEM study. J Appl Polym Sci 104(2):909–914

Rodrigues Filho G, da Cruz SF, Pasquini D, Cerqueira DA, Prado VD, de Assuncao RMN (2000) Water flux through cellulose triacetate films produced from heterogeneous acetylation of sugar cane bagasse. J Membr Sci 177(1–2):225–231

Rodrigues Filho G, da Silva RC, Meireles CD, da Assuncao RMN, Otaguro H (2005) Water flux through blends from waste materials: cellulose acetate (from sugar cane bagasse) with polystyrene (from plastic cups). J Appl Polym Sci 96(2):516–522

Rodrigues Filho G, Toledo LC, Cerqueira DA, de Assuncao RMN, Meireles CD, Otaguro H, Rogero SO, Lugao AB (2007) Water flux, DSC, and cytotoxicity characterization of membranes of cellulose acetate produced from sugar cane bagasse, using PEG 600. Polym Bull 59(1):73–81

Rodrigues Filho G, de Assuncao RMN, Vieira JG, Meireles CD, Cerqueira DA, Barud HD, Ribeiro SJL, Messaddeq Y (2007) Characterization of methylcellulose produced from sugar cane bagasse cellulose: crystallinity and thermal properties. Polym Degrad Stab 92(2):205–210

Vieira RGP, Meireles CS, de Assunção RMN, Filho GR (2004) In: Production and characterization of methylcellulose from sugar cane bagasse, 5th International symposium on natural polymers and composites; 8th Brazilian symposium on the chemistry of lignins and the other wood components. São Pedro-SP, Brazil, pp 1–3

Vieira RGP, Rodrigues Filho G, de Assuncao RMN, Meireles CDS, Vieira JG, de Oliveira GS (2007) Synthesis and characterization of methylcellulose from sugar cane bagasse cellulose. Carbohydr Polym 67(2):182–189

Viera RGP (2004) Síntese e caracterização da metilcelulose a partir da metilação heterogênea do bagaço de cana-de-açúcar. Universidade Federal de Uberlândia, Uberlândia, MG, Brazil

IBGE (2010) http://www.ibge.gov.br/home/estatistica/indicadores/agropecuaria/lspa/lspa_201005_5.shtm. Accessed 28 May 2010

Copersucar (2010) http://www.copersucar.com.br/institucional/por/academia/cana_acucar.asp. Accessed 28 May 2010

Olle D, Lozano YF, Brillouet JM (1996) Isolation and characterization of soluble polysaccharides and insoluble cell wall material of the pulp from four mango (Mangifera indica L) cultivars. J Agric Food Chem 44(9):2658–2662

Ajila CM, Bhat SG, Rao UJSP (2007) Valuable components of raw and ripe peels from two Indian mango varieties. Food Chem 102(4):1006–1011

Velan M, Krishnan MRV, Lakshmanan CM (1995) Conversion of mango kernel starch to glucose syrups by enzymatic-hydrolysis. Bioprocess Eng 12(6):323–326

Chou WL, Yu DG, Yang MC, Jou CH (2007) Effect of molecular weight and concentration of PEG additives on morphology and permeation performance of cellulose acetate hollow fibers. Sep Purif Technol 57(2):209–219

Meireles CD (2007) Síntese e caracterização de membranas de acetato de celulose, obtido do bagaço de cana-de-açúcar, e blendas de acetato de celulose com poliestireno de copos plásticos descartados. Universidade Federal de Uberlândia, Uberlândia, MG, Brazil

Sossna M, Hollas M, Schaper J, Scheper T (2007) Structural development of asymmetric cellulose acetate microfiltration membranes prepared by a single-layer dry-casting method. J Membr Sci 289(1–2):7–14

Delanaye P, Lambermont B, Dogne JM, Dubois B, Ghuysen A, Janssen N, Desaive T, Kolh P, D’Orio V, Krzesinski JM (2006) Confirmation of high cytokine clearance by hemofiltration with a cellulose triacetate membrane with large pores: an in vivo study. Int J Artif Organs 29(10):944–948

Duarte AP, Bordado JC, Cidade MT (2007) Cellulose acetate reverse osmosis membranes: optimization of preparation parameters. J Appl Polym Sci 103(1):134–139

Ismail AF, Hassan AR (2004) The deduction of fine structural details of asymmetric nanofiltration membranes using theoretical models. J Membr Sci 231(1–2):25–36

Kalocheretis P, Vlamis I, Belesi C, Makriniotou I, Zerbala S, Savidou E, Zorbas S, Arvanitis N, Iatrou C (2006) Residual blood loss in single use dialyzers: effect of different membranes and flux. Int J Artif Organs 29(3):286–292

Kesting RE (1985) Synthetic polymeric membranes: a structural perspective, 2nd edn. Wiley, New York

Puleo AC, Paul DR, Kelley SS (1989) The effect of degree of acetylation on gas sorption and transport behavior in cellulose-acetate. J Membr Sci 47(3):301–332

Rodrigues Filho G, Monteiro DS, Meireles CD, de Assuncao RMN, Cerqueira DA, Barud HS, Ribeiro SJL, Messadeq Y (2008) Synthesis and characterization of cellulose acetate produced from recycled newspaper. Carbohydr Polym 73(1):74–82

Knaus S, Bauer-Heim B (2003) Synthesis and properties of anionic cellulose ethers: influence of functional groups and molecular weight on flowability of concrete. Carbohydr Polym 53(4):383–394

Sperling LH (1992) Introduction to physical polymer science, 2nd edn. Wiley, New York

Khulbe KC, Matsuura T, Lamarche G, Lamarche AM, Choi C, Noh SH (2001) Study of the structure of asymmetric cellulose acetate membranes for reverse osmosis using electron spin resonance (ESR) method. Polymer 42(15):6479–6484

He JX, Zhang M, Cui SZ, Wang SY (2009) High-quality cellulose triacetate prepared from bamboo dissolving pulp. J Appl Polym Sci 113(1):456–465

Mark JE (1999) Polymer data handbook. Oxford University Press, Oxford

Sassi JF, Chanzy H (1995) Ultrastructural aspects of the acetylation of cellulose. Cellulose 2(2):111–127

Mulder M (1997) Basic principles of membranes technology, 2nd edn. Edition Academic Publishers, The Netherlands

Acknowledgments

The authors acknowledge to CNPq for project Casadinho UFU/UFG/UFMS (620181/2006-0), to CAPES for the access to “Portal Periódicos”, to Finep/Sebrae for project 0535/07 ref 3119/06. Meireles thanks CAPES for her PhD scholarship, Ribeiro thanks FAPEMIG for the scholarships related to projects PIBIC A-025/2008 e EX—APQ-00466-08.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ferreira Júnior, M.F., Mundim, E.A.R., Filho, G.R. et al. SEM study of the morphology of asymmetric cellulose acetate membranes produced from recycled agro-industrial residues: sugarcane bagasse and mango seeds. Polym. Bull. 66, 377–389 (2011). https://doi.org/10.1007/s00289-010-0346-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-010-0346-2