Abstract

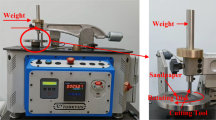

This paper addresses the hydroabrasive disintegration of the difficult-to-machine material, Monel K-500. An experiment was performed using a hydroabrasive cutting system with an additional rotating module. The objective of the preliminary experiments was to identify significant technological factors and investigate their impact on the machined surface quality of difficult-to-machine materials. To describe the impact of parameters, experiments were carried out according to the design of experiment. Surface roughness parameters were measured, and surface topography visualisation and analysis were conducted. The results concluded that the abrasive mass flow rate and traverse speed significantly influence the surface roughness and material removal rate. From a practical point of view, the technology can prepare semi-finished workpiece shapes; however, surface finishing is necessary.

Similar content being viewed by others

References

Liu D, Huang CZ, Wang J, Zhu HT, Yao P, Liu ZW (2013) Study on the effect of standoff distance on processing performance of alumina ceramics in two modes of abrasive waterjet turning patterns. Adv Mater Res 797:21–26. https://doi.org/10.4028/www.scientific.net/AMR.797.21

Ansari AI, Hashish M (1992) On the modeling of abrasive waterjet turning. B chapter:555–576

Sitek L, Foldyna J, Souček K (2005) Shaping of rock specimens for testing of uniaxial tensile strength by high speed abrasive water jet: first experience. Impact Hum Act Geol Environ — Proc Int Symp Int Soc Rock Mech Eurock 2005

Srivastava AK, Nag A, Dixit AR, Tiwari S, Scucka J, Zelenak M, Hloch S, Hlavacek P (2017) Surface integrity in tangential turning of hybrid MMC A359/B4C/Al2O3 by abrasive waterjet. J Manuf Process 28:11–20. https://doi.org/10.1016/j.jmapro.2017.05.017

Twardowski P, Legutko S, Krolczyk GM, Hloch S (2015) Investigation of wear and tool life of coated carbide and cubic boron nitride cutting tools in high speed milling. Adv Mech Eng 7(6):1–9. https://doi.org/10.1177/1687814015590216

Krolczyk GM, Nieslony P, Legutko S (2015) Determination of tool life and research wear during duplex stainless steel turning. Arch Civ Mech Eng 15(2):347–354. https://doi.org/10.1016/j.acme.2014.05.001

Monka P, Monkova K, Balara M et al (2016) Design and experimental study of turning tools with linear cutting edges and comparison to commercial tools. Int J Adv Manuf Technol 85(9-12):2325–2343. https://doi.org/10.1007/s00170-015-8065-3

Manu R, Babu NR (2009) An erosion-based model for abrasive waterjet turning of ductile materials. Wear 266(11-12):1091–1097. https://doi.org/10.1016/j.wear.2009.02.008

Junkar M, Jurisevic B, Fajdiga M, Grah M (2006) Finite element analysis of single-particle impact in abrasive water jet machining. Int J Impact Eng 32(7):1095–1112. https://doi.org/10.1016/j.ijimpeng.2004.09.006

Uhlmann E, Flögel K, Kretzschmar M, Faltin F (2012) Abrasive waterjet turning of high performance materials. Procedia CIRP, In, pp 409–413

Hloch S, Hlaváček J, Vasilko K et al (2014) Abrasive waterjet (AWJ) titanium tangential turning evaluation. Meta 53:537–540

Zohoor M, Zohourkari I, Cacciatore F, Annoni M (2014) Influence of machining parameters on part geometrical error in abrasive waterjet offset-mode turning. Proc Inst Mech Eng Part B J Eng Manuf 229(12):2125–2133. https://doi.org/10.1177/0954405414548462

Hashish M, South A (1991) Optimization factors in abrasive- waterjet machining. J Eng Ind (1)

Ansari AI, Hashish M (1995) Effect of abrasive waterjet parameters on volume removal trends in turning. J Eng Ind 117(4):475–484. https://doi.org/10.1115/1.2803524

Ali MA, Fan JM, Zhu HT, Wang J (2013) A visualization study of the radial-mode abrasive waterjet turning process for alumina ceramics. Adv Mater Res 797:9–14. https://doi.org/10.4028/www.scientific.net/AMR.797.9

Ansari AI, Hashish M, Ohadi MM (1992) Flow visualization study of the macromechanics of abrasive-waterjet turning. Exp Mech 32(4):358–364. https://doi.org/10.1007/BF02325589

Qi H, Fan J, Wang J (2014) A study of the micro-machining process on quartz crystals using an abrasive slurry jet. Proc Inst Mech Eng Part B J Eng Manuf 229(3):421–434. https://doi.org/10.1177/0954405414528167

Courbon C, Sajn V, Kramar D, Rech J, Kosel F, Kopac J (2011) Investigation of machining performance in high pressure jet assisted turning of Inconel 718: a numerical model. J Mater Process Technol 211(11):1834–1851. https://doi.org/10.1016/j.jmatprotec.2011.06.006

Axinte DA, Stepanian JP, Kong MC, McGourlay J (2009) Abrasive waterjet turning—an efficient method to profile and dress grinding wheels. Int J Mach Tools Manuf 49(3-4):351–356. https://doi.org/10.1016/j.ijmachtools.2008.11.006

Zhong ZW, Han ZZ (2002) Turning of glass with abrasive waterjet. Mater Manuf Process 17(3):339–349. https://doi.org/10.1081/AMP-120005380

Hlaváček P, Cárach J, Hloch S et al (2015) Sandstone turning by abrasive waterjet. Rock Mech Rock Eng 48(6):2489–2493. https://doi.org/10.1007/s00603-015-0719-9

Cárach J, Hloch S, Hlaváček P et al (2016) Tangential turning of Incoloy alloy 925 using abrasive water jet technology. Int J Adv Manuf Technol 82(9-12):1747–1752. https://doi.org/10.1007/s00170-015-7489-0

Sangwan KS, Saxena S, Kant G (2015) Optimization of machining parameters to minimize surface roughness using integrated ANN-GA approach. Procedia CIRP 29:305–310. https://doi.org/10.1016/j.procir.2015.02.002

Li W, Zhu H, Wang J et al (2013) An investigation into the radial-mode abrasive waterjet turning process on high tensile steels. Int J Mech Sci 77:365–376. https://doi.org/10.1016/j.ijmecsci.2013.05.005

Yue Z, Huang C, Zhu H et al (2014) Optimization of machining parameters in the abrasive waterjet turning of alumina ceramic based on the response surface methodology. Int J Adv Manuf Technol 71(9-12):2107–2114. https://doi.org/10.1007/s00170-014-5624-y

Hutyrová Z, Hloch S, Hlavá P, Zele M (2015) Turning of wood plastic composites by water jet and abrasive water jet. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-015-7831-6

Manu R, Babu NR (2008) Influence of jet impact angle on part geometry in abrasive waterjet turning of aluminium alloys. Int J Mach Mach Mater 3(1/2):120. https://doi.org/10.1504/IJMMM.2008.017629

Zohourkari I, Zohoor M, Annoni M (2014) Investigation of the effects of machining parameters on material removal rate in abrasive waterjet turning. Adv Mech Eng 6:624203. https://doi.org/10.1155/2014/624203

Liu D, Huang C, Wang J, Zhu H, Yao P, Liu ZW (2014) Modeling and optimization of operating parameters for abrasive waterjet turning alumina ceramics using response surface methodology combined with Box-Behnken design. Ceram Int 40(6):7899–7908. https://doi.org/10.1016/j.ceramint.2013.12.137

Kartal F, Gokkaya H (2013) Turning with abrasive water jet machining—a review. Eng Sci Technol an Int J 16:113–122

Cárach J, Hloch S, Hlaváček P, et al (2016) Hydro-abrasive disintegration of alloy Monel K-500-the influence of technological and abrasive factors on the surface quality. In: Procedia Eng. pp 17–23

Hromasová M, Kic P, Müller M, Linda M (2017) Evaluation of quality and efficiency of ventilation equipment by scanning electron microscopy. Agron Res 15:1014–1023

Wang J (1999) Abrasive waterjet machining of polymer matrix composites–cutting performance, erosive process and predictive models. Int J Adv Manuf Technol 15(10):757–768. https://doi.org/10.1007/s001700050129

Hashish M (1991) Characteristics of surfaces machined with abrasive-waterjets. J Eng Mater Technol 113(3):354–362. https://doi.org/10.1115/1.2903418

Finnie I (1958) The mechanism of erosion of ductile metals. 3rd US Natl Congr Appl Mech

Paul S, Hoogstrate AM, Van Luttervelt CA, Kals HJJ (1998) Analytical and experimental modelling of the abrasive water jet cutting of ductile materials. J Mater Process Technol 73(1-3):189–199. https://doi.org/10.1016/S0924-0136(97)00228-8

Funding

This paper was supported by the Slovak Research and Development Agency, under contract no. APVV-207-12. Experiments were carried out with the support of the Institute of Clean Technologies for Mining and Utilization of Raw Materials for Energy Use—Sustainability Program, Reg. No. LO1406, financed by the Ministry of Education, Youth, and Sports of the Czech Republic and with support for the long-term conceptual development of the research institution RVO: 68145535.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cárach, J., Hloch, S., Petrů, J. et al. Hydroabrasive disintegration of rotating Monel K-500 workpiece. Int J Adv Manuf Technol 96, 981–1001 (2018). https://doi.org/10.1007/s00170-018-1653-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1653-2