Abstract

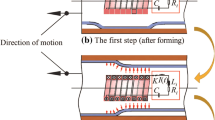

Magnetic pulse cladding (MPC), a new technology, is proposed in this study to fabricate often utilized bi-metal tubing in engineering applications with an outer tubular component consisting of structurally strong material and an inner tubular layer of corrosion-resistant material. The MPC process includes an innovative feature that allows the outer and inner tubes to electromagnetically bond together by a sequential expansion process to form a mechanical bond between the tubes at the interface. The MPC process was experimentally arranged to produce an Al/Fe bi-metal tube with an outer carbon steel tube and an internal aluminum tube. A mechanical test was then applied to characterize bonding strength of the Al/Fe bi-metal tube. Significant process parameters including discharging voltage, radial gap, and feeding length were identified based on bonding strength influence. Overall feasibility was demonstrated for the MPC process in electromagnetic expansion pattern in the production of bi-metal tubing.

Similar content being viewed by others

References

Mohammad SM, Abbas A (2011) Fabrication of copper/aluminum composite tubes by spin-bonding process: experiments and modeling. Int J Adv Manuf Technol 54:1043–1055

Zhan Z, He Y, Wang D, Gao W (2006) Cladding inner surface of steel tubes with Al foils by ball attrition and heat treatment. Surf Coat Technol 201:2684–2689

Henryk D, Maciej P (1983) On the theory of the process of hot rolling of bimetal plate and sheet. J Mech Work Technol 8(4):309–325

Sun XJ, Tao J, Guo XZ (2011) Bonding properties of interface in Fe/Al clad tube prepared by explosive welding. Trans Nonferrous Metals Soc 21:2175–2180

Sponseller DL, Timmons GA, Bakker WT (1998) Development of clad boiler tubes extruded from bimetallic centrifugal castings. J Mater Eng Perform 7(2):227–238

Chen Z, Ikeda K, Murakami T, Takeda T, Xie JX (2003) Fabrication of composite pipes by multi-billet extrusion technique. J Mater Process Technol 137(1):10–16

Berski S, Dyja H, Maranda A, Nowaczewski J, Banaszek G (2006) Analysis of quality of bimetallic rod after extrusion process. J Mater Process Technol 177(1):582–586

Mohebbi MS, Akbarzadeh A (2010) A novel spin-bonding process for manufacturing multilayered clad tubes. J Mater Process Technol 210:510–517

Yoshida T, Mann T, Matsuda S, Matsui S, Atsuta T, Toma S, Itoga K (1981) The development of corrosion-resistant tubing. In: Proceedings of the 1981 OTC Annual Offshore Technology Conference, Houston 365–378

Wang X, Li P, Wang R (2005) Study on hydro-forming technology of manufacturing bimetallic CRA-lined pipe. Int J Mach Tools Manuf 45:373–378

Xu JR, Yu HP, Li CF (2013) Effects of process parameters on electromagnetic forming of AZ31 magnesium alloy sheets at room temperature. Int J Adv Manuf Technol 66:1591–1602

Cui XH, Mo JH, Han F (2012) 3D multi-physics field simulation of electromagnetic tube forming. Int J Adv Manuf Technol 59(5–8):521–529

Xu JR, Cui JJ, Lin QQ, Li CF (2014) Effects of driver sheet on magnetic pulse forming of AZ31 magnesium alloy sheets. Int J Adv Manuf Technol 72:791–800

Psyk V, Risch D, Kinsey BL, Tekkayaa AE, Kleiner M (2011) Electromagnetic forming—a review. J Mater Process Technol 211:787–829

Mori K, Bay N, Fratini L, Micari F, Tekkaya AE (2013) Joining by plastic deformation. CIRP Ann Manuf Technol 62(2):673–694

Groche P, Wohletz S, Brenneis M, Pabst C, Resch F (2014) Joining by forming—a review on joint mechanisms, applications and future trends. J Mater Process Technol 214(10):1972–1994

Weddeling C, Woodward ST, Marré M, Nellesen J, Psyk V, Tekkaya AE, Tillmann W (2011) Influence of groove characteristics on strength of form-fit joints. J Mater Process Technol 211(5):925–935

Marré M, Brosius A, Tekkaya AE (2008) Joining by compression and expansion of (none-) reinforced profiles. Adv Mater Res Flex Manuf Lightweight Frame Struct Phase II Integr 43:57–68

Geier M, José MM, Rossi R, Rosa PAR, Martins PAF (2013) Interference-fit joining of aluminum tubes by electromagnetic forming. Adv Mater Res 853:488–493

Barreiro P, Beerwald C, Homberg W, Kleiner M, Löhe D, Marré M, Schulze V (2006) Strength of tubular joints made by electromagnetic compression at quasi-static and cyclic loading. In: International Conference on High Speed Forming, Germany 107–117

Johnson W (1972) Impact strength of materials. Edward Arnold, London

Seth M, Vohnout VJ, Daehn GS (2005) Formability of steel sheet in high velocity impact. J Mater Process Technol 168(3):390–400

Xu JR, Cui JJ, Lin QQ, Li YR, Li CF (2014) Magnetic pulse forming of AZ31 magnesium alloy shell by uniform pressure coil at room temperature. Int J Adv Manuf Technol 77:289–304

Golovashchenko SF, Gillard AJ, Mamutov AV, Ibrahim R (2014) Pulsed electrohydraulic springback calibration of parts stamped from advanced high strength steel. J Mater Process Technol 214(11):2796–2810

Yu HP, Li CF (2007) Effects of coil length on tube compression in electromagnetic forming. Trans Nonferrous Metals Soc 17(6):1270–1275

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, Z., Yu, H., Meng, F. et al. Experimental investigation on fabrication of Al/Fe bi-metal tubes by the magnetic pulse cladding process. Int J Adv Manuf Technol 83, 1409–1418 (2016). https://doi.org/10.1007/s00170-015-7671-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7671-4