Abstract

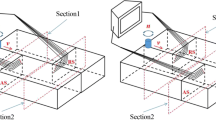

Temperature and material flow behavior during friction spot welding of Alclad 7B04-T74 aluminum alloy were studied by both numerical simulation and welding experiment. The Alclad 7B04-T74 aluminum alloy sequentially experienced solid solution treatment at 465 °C, low temperature artificial aging at 120 °C, and high temperature artificial aging at 180 °C. During welding, the material which flowed into the sleeve cavity suffered from higher temperature, and the peak temperature in the stir zone was higher than the incipient melting temperature of the base material. Accordingly, the eutectic films along the grain boundaries can be observed in the stir zone after welding. The peak temperatures in the thermo-mechanically affected zone and the heat affected zone were lower than the solution temperature and higher than the artificial aging temperature of the base material. In the sleeve retreating stage of the welding process, the material in the sleeve cavity flowed downward out of the sleeve cavity, and then it flowed laterally and upward to fill the gap left by the retreating sleeve. Such a material flow path resulted in the “U-shaped” morphology of the bonding ligament, the upward curving of the hook, and the upward distortion of the grains in the thermo-mechanically affected zone.

Similar content being viewed by others

References

Suhuddin UFH, Fischer V, dos Santos JF (2013) The thermal cycle during the dissimilar friction spot welding of aluminum and magnesium alloy. Scr Mater 68:87–90

Zhao YQ, Liu HJ, Lin Z, Chen SX, Hou JC (2014) Microstructures and mechanical properties of friction spot welded Alclad 7B04-T74 aluminium alloy. Sci Technol Weld Join 19:617–622

Zhao YQ, Liu HJ, Chen SX, Lin Z, Hou JC (2014) Effects of sleeve plunge depth on microstructures and mechanical properties of friction spot welded alclad 7B04-T74 aluminum alloy. Mater Des 62:40–46

Lathabai S, Painter MJ, Cantin GMD, Tyagi VK (2006) Friction spot joining of an extruded Al-Mg-Si alloy. Scripta Mater 55:899–902

Solanki KN, Jordon JB, Whittington W, Rao H, Hubbard CR (2012) Structure–property relationships and residual stress quantification of a friction stir spot welded magnesium alloy. Scripta Mater 66:797–800

Jonckheere C, de Meester B, Cassiers C, Delhaye M, Simar A (2012) Fracture and mechanical properties of friction stir spot welds in 6063-T6 aluminum alloy. Int J Mach Tools Manuf 62:569–575

Karthikeyan R, Balasubramanian V (2010) Predictions of the optimized friction stir spot welding process parameters for joining AA2024 aluminum alloy using RSM. Int J Mach Tools Manuf 51:173–183

Song X, Ke L, Xing L, Liu F, Huang C (2014) Effect of plunge speeds on hook geometries and mechanical properties in friction stir spot welding of A6061-T6 sheets. Int J Mach Tools Manuf 71:2003–2010

Oliveira PHF, Amancio-Filho ST, dos Santos JF, Hage E Jr (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64:2098–2101

Amancio-Filho ST, Bueno C, dos Santos JF, Huber N, Hage E Jr (2011) On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater Sci Eng A 528:3841–3848

Tier MD, Rosendo TS, dos Santos JF, Huber N, Mazzaferro JA, Mazzaferro CP et al (2013) The influence of refill FSSW parameters on the microstructure and shear strength of 5042 aluminium welds. J Mater Process Technol 213:997–1005

Rosendo T, Parra B, Tier MAD, da Silva AAM, dos Santos JF, Strohaecker TR et al (2011) Mechanical and microstructural investigation of friction spot welded AA6181-T4 aluminium alloy. Mater Des 32:1094–1100

Karim H, Sindhura K, William J (2010) Simulation of a refill friction stir spot welding process using a fully coupled thermo-mechanical FEM model. J Manuf Sci Eng 132:014503-1-5

Shen Z, Yang X, Yang S, Zhang Z, Yin Y (2014) Microstructure and mechanical properties of friction spot welded 6061-T4 aluminum alloy. Mater Des 54:766–778

Shen Z, Yang X, Zhang Z, Cui L, Li T (2013) Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater Des 44:476–486

Suhuddin U, Fischer V, Kroeff F, dos Santos JF (2014) Microstructure and mechanical properties of friction spot welds of dissimilar AA5754 Al and AZ31 Mg alloys. Mater Sci Eng A 590:384–389

Campanelli LC, Suhuddin UFH, Antonialli AIS, dos Santos JF, de Alcantara NG, Bolfarini C (2013) Metallurgy and mechanical performance of AZ31 magnesium alloy friction spot welds. J Mater Process Technol 213:515–521

Shen J, Suhuddin UFH, Cardillo MEB, dos Santos JF (2014) Eutectic structures in friction spot welding joint of aluminum alloy to copper. Appl Phys Lett 104:191901

Buffa G, Hua J, Shivpuri R, Fratini L (2006) A continuum based FEM model for friction stir welding—model development. Mater Sci Eng A 419:389–396

Fratini L, Buffa G, Shivpuri R (2010) Mechanical and metallurgical effects of in process cooling during friction stir welding of AA7075-T6 butt joints. Acta Mater 58:2056–2067

Fratini L, Buffa G, Shivpuri R (2007) Improving friction stir welding of blanks of different thicknesses. Mater Sci Eng A 459:209–215

Gerlich A, Yamamoto M, North TH (2008) Local melting and tool slippage during friction stir spot welding of Al-alloys. J Mater Sci 43:2–11

Gerlich A, Avramovic-Cingara G, North TH (2006) Stir zone microstructure and strain rate during Al 7075-T6 friction stir spot welding. Metall Mater Trans A 37A:2773–2786

Gerlich A, Yamamoto M, North TH (2007) Strain rates and grain growth in Al 5754 and Al 6061 friction stir spot welds. Metall Mater Trans A 38:1291–1302

Hassan KAA, Prangnell PB, Norman AF, Price DA, Williams SW (2003) Effect of welding parameters on nugget zone microstructure and properties in high strength aluminium alloy friction stir welds. Sci Technol Weld Join 8:257–268

Colegrove PA, Shercliff HR (2003) Experimental and numerical analysis of aluminium alloy 7075-T7351 friction stir welds. Sci Technol Weld Join 8:360–368

Song M, Kovacevic R (2003) Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int J Mach Tools Manuf 43:605–615

Buffa G, Fratini L, Shivpuri R (2007) CDRX modelling in friction stir welding of AA7075-T6 aluminum alloy: analytical approaches. J Mater Process Technol 191:356–359

Davis JY (1993) Properties and selection nonferrous alloys and special purpose materials ASM handbook 2: 455–62

Porter DA, Easterling KE (1981) Phase transformations in metals and alloys. Van Nostrand Reinhold, Wokingham

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Y., Liu, H., Yang, T. et al. Study of temperature and material flow during friction spot welding of 7B04-T74 aluminum alloy. Int J Adv Manuf Technol 83, 1467–1475 (2016). https://doi.org/10.1007/s00170-015-7681-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7681-2