Abstract

The binary alloy Mn0.5+xBi0.5−x, x ⩽ 0.05, is a promising rare-earth-free magnetic material, with high-energy-density (a critical characteristic for electric motors and power electronics), low cost, and significant magnetic properties for multiple uses at room temperature. In this article, we report how a free Bi, when precipitated over Mn0.5+xBi0.5−x (x ⩽ 0.05) of small crystallites, diffuses back into a stable Mn0.5+xBi0.5−x, x → 0, via a peritectic reaction, which facilitates preferential growth of small core–shell crystallites with multiple facets, having the potential for tailored magnetic properties. This growth travels slowly in the anisotropic channels of vacancies on annealing the reactive nanopowder at a critical 573 K temperature in Ar gas. Thus, an initial crystallite size of D ∼ 27 nm grows to only 38 nm in a reaction extended over a period of 96 h. A transient phase, x > 0, which has Bi vacancies, primarily grows in the (101) and (110) facets, filling the vacancies over a 6.41% larger crystal density. If any excess Mn is present, it segregates over a saturated phase, combines with free Bi, and ultimately forms a stable alloy phase. The small crystallites contain an inbuilt surface Bi-layer (shell), with a 1–2 nm thickness, in a core–shell of nanoplates (20–60 nm width), as shown in the high resolution transmission electron microscope images. In the proposed microscopic model, with hybridized Mn-d5 and Bi-p3 electrons (also spins), the magnetic properties are readily controlled. Thus, at 300 K, a maximum coercivity Hc = 9.850 kOe (14.435 kOe at 350 K) develops (Hc = 5.010 kOe in the initial) in critical single domains (D ∼ 33 nm). A net 72.5 emu g−1 magnetization occurs, with an enhanced TC = 641.5 K (600.5 K at x ∼ 0.05) on an order of enhanced anisotropy constant K1, demonstrating the significant effects of this core–shell structure of small crystallites.

Export citation and abstract BibTeX RIS

1. Introduction

Hierarchical microscopic assemblies (or clusters) of randomly aligned anisotropic crystallites of single ferromagnetic (FM) domains have been found to exhibit promising magnetic properties, in terms of coercivity Hc, remnant magnetization Mr, and energy-density (BH)max in a wide hysteresis loop, owing to the control exerted by collective spin dynamics over magnetocrystalline (K1), shape (Ha), and surface (Hs) anisotropies in individual crystallites [1–19]. Geometrical shapes, cleaved facets, configuration of surface spins, lattice defects, and twined boundaries are vital variants required to tailor the nontrivial microscopic features of the collective spin dynamics of single domains, and mutual exchange interactions between tiny modules in a cluster, at a wider length scale in the nanometer-to-submicrometer range. Bridging over a thin diamagnetic (Dm) surface layer (such as B, P, Bi, or some metal oxides) on such magnets can interlock the surface spins in an exchange-coupled network over the core of a robust core–shell magnet. Usefully, Bi shares a large orbital magnetic moment of μℓ = −0.27 μB per atom [2, 14], that enables the engineering of a model hybrid FM–Dm composite magnet of small core–shell crystallites. Here, surface spins are firmly pinned down at the crystal facets in an anisotropic shape of reversed domains. This prevents their continuous, undisrupted running over several domains of a multiple structure.

Magnetic materials are a clean-energy source, with wide-tranmging applications such as power generators, electric motors, micro-electro-mechanical systems (MEMS), power electronics, automobiles, medicine, wind turbines, sensors, and magnetic valves [1–19]. In particular, the rare-earth-free alloy, Mn0.45+xBi0.55−x, 0 ⩽ x ⩽ 0.10, has been intensively studied as an alternative magnetic material to replace Nd2Fe14B [5, 17] and SmCo5 [5, 14], in view of the relative scarcity and higher costs of the rare earth metals employed in the alloys for these types of powerful magnets [12–14]. Here, Mn-3d5 spins occupy only just under half of the net interstices, x ⩽ 0.10, in a NiAs-type hexagonal crystal lattice (P63/mmc space group) of an F order, which shares a net spin magnetic moment μs = 3.84 μB per Mn atom (81.3 emu g−1) [13, 14]. A small μℓ = −0.27 μB is generally set-up antiparallel to the μs in Bi-6sp3 sites in the process of p-d hybridization between Mn and Bi atoms [2, 14]. This is a so-called low temperature phase (LTP), with μs and μℓ lying collinearly along the crystallographic c-axis, with a large K1 = 1.8 × 107 erg cm−3 at room temperature [7, 13], a high Hc of a uniquely positive temperature coefficient at higher temperatures [7, 9], a high Kerr effect [6, 13], and a high spin-polarization [6], unlike other high-energy magnets. Below the critical temperature Tsr = 140 K (a spin-reorientation transition, SRT), the μℓ and μs gradually skip away from the c-axis and set-up along the basal a-b plane below 90 K [2, 12]. While heating, a coupled structural-magnetic transition turns into the high-temperature-phase (HTP) of a paramagnet at TC = 628 K (i.e. also the LTP Curie point) [8, 12]. This is a NiAs-type disordered hexagonal lattice [2, 7], which is also ferromagnetic if cooled rapidly, having an even larger K1, but rather smaller μs and TC points [7, 12]. Nearly 4% excess Mn is generated in a congruent decomposition, Mn0.5Bi0.5 → Mn0.50Bi0.46 + 0.04Bi, which fills-up Bi vacancies at any antisites present in a sample, unless cured by post-thermal annealing [10, 12]. This has an adverse effect on net magnetization and other useful magnetic properties.

An alloy of Mn0.5+xBi0.5−x, x ⩽ 0.05, is pulverized and annealed into a fine powder of small crystallites from a bulk of arc melt ingots [9, 20–23], or melt-spun ribbons [6, 24–26], giving rise to a high LTP-phase of superior (BH)max, Hc, and Mr values. A huge (BH)max ∼ 16 MGOe is expected to occur as a result of a critical Hc ∼ 37 kOe in a square B-H loop, assuming a nucleation field of Ha = 2K1/Ms ≅ 56 kOe in a sample of single domains, with Ms = 72.5 emu g−1 saturation magnetization and K1 = 1.8 × 107 erg cm−3 at 295 K [13]. All observed Hc and (BH)max values to date stand far below the theoretical values. For example, small MnBi crystallites, D ≡ 20–30 nm size, of a spark-erosion exhibit Hc = 10 kOe and (BH)max = 3.0 MGOe [27]. A larger Hc = 22.3 kOe evolves at a scarified magnetization, being nearly 37.0 emu g−1 at H ⩽ 23 kOe, in a magnetically aligned Mn0.55Bi0.45 of thin sheets (arc melt ingots wet milled in oleyamine and oleic acid) of a thickness of a few tens of nanometers [9]. Further, MnBi nanocrystals deduced by co-reducing Mn2+/Bi3+ salts in a liquid bath exhibit Ms = 49.0 emu g−1 and Hc = 15.0 kOe [28, 29]. A reactive sintering of the Mn and Bi small particles of a Mn0.55Bi0.45 alloy yields a lower Hc ⩽ 8.0 kOe [30]. A larger Hc = 16.3 kOe, but a far lower Ms = 22.0 emu g−1, occurs in the composite alloy of MnBi–Bi generated by a calcio-thermic Mn-Bi2O3 reduction in Ar gas [31]. A technical aspect relating to such a fine powder of small and separated MnBi crystallites is that it can be dispersed evenly on a soft magnet (such as Fe, Co, or ferrites) in order to fabricate a polymer bonded and/or an exchange-coupled magnet with increased magnetic properties [32–35].

In terms of first-principles calculations, a Bi deficient Mn0.55Bi0.45 crystal lattice has Mn-3d5 spins in bipyramidal interstitial sites (antisites), which align opposite the regular Mn sites [36], i.e. a lower average Ms value. Generally, a minimum level of electrical resistivity (the Kondo effect) develops in cases of positive magnetoresistance at low temperatures, ⩽10 K, based on a small Pt → Mn doping (⩽4.5 at %), possibly due the greater density of Pt-5d8s2 valence electrons, and local spin disorder. Here, Bi-p3 states dominate near the Fermi level of a major source of K1 energy at low temperatures. The dispersions of phonons/elastic moduli and magnetoelastic-coupling increase multiple features of multiferroics [37, 38]. The numerous magnetic properties of a Mn0.5Bi0.5 module have been studied, in relation to its band structure, using local spin-density approximation (LSDA) with on-site Coulomb correlations (LSDA + U), to predict equilibrium magnetic moments on Mn sites, as well as temperature K1 behaviour [7]. An inversion of the anisotropic pairwise exchange interaction between Bi atoms is found to be responsible for the SRT signal [7]. Further, Choi et al [39] used density functional theory (DFT) to account for the anisotropic change of lattice and Mn-Bi hybridization in a coupled transition of a uniaxial to in-plane anisotropy K1 across the SRT at low temperatures. In general, all such features are strongly dependent on the internal structure of a sample in a due force-field of its anisotropic shape, dimension and surfaces, in terms of its small crystallites. Multiple twins displaced in different orientations in a nanonscale model martensite and/or an austenite alloy perform well in terms of the phase-field theory of transformations between martensitic variants, and multiple twining within martensitic variants for large strains and rotations [40, 41]. This resolves several nontrivial features of the anisotropic growth of small architects in a complex hierarchical structure.

Nevertheless, no systematic study is currently available based on a microscopic view of finely tailored magnetic properties in a sample of small Mn0.5+xBi0.5−x, x ⩽ 0.05, core–shell crystallites (single domains). A chemical synthesis [28, 29] or a wet-milling of such alloys (and their critical annealing processes [9, 21, 34]) finely tunes the alloy's magnetic properties, due to the tailored shape, surface topology, anisotropic growth in facets, lattice defects, and twin boundaries in the small crystallites [9, 27, 35]. This represents a high-entropy sample of a robust spin-cluster of the randomly aligned spins of single domains of small crystallites. Here, we report how such small crystallites grow in a local surface reaction when heated with a free Bi (liquid) in a composite alloy, comprising Mn0.5+xBi0.5−x−Bi, x ⩽ 0.05, and ⩽ 8 at% Bi, in a reactive powder, at a critical Th = 573 K temperature. Some of the Bi binds (as a shell) over the resulting crystallites of the small Mn0.5+xBi0.5−x−Bi core–shells. The proposed model takes account of the fact that spins can be firmly pinned down at the surfaces of the stable domain walls in a stable core–shell sample. The results are demonstrated using high resolution transmission electron microscope (HRTEM) images, x-ray diffraction (XRD), and the tailored magnetic properties of optimally annealed samples.

2. Experimental details

A master alloy, Mn0.5+xBi0.5−x−Bi (x ⩽ 0.05, ⩽8 at% Bi), was prepared in the form of small discs (having diameters of 20 mm and widths of 8–10 mm) by melting and casting a mixture of pure Mn and Bi metals (99.9% purity) in a vacuum arc melting device, as used in previous works [42, 43]. In order to control any mass loss, the Bi melts first, and is slowly allowed to evaporate before it is blended with the Mn to form an alloy; small Mn and Bi chips were layered alternately, one above the other, in a mould, in such a way that as soon as the Bi had melted (melting point Tm = 544 K), it locally dissolved the Mn (Tm = 1519 K), forming an alloy in a liquid–solid reaction, in order to obtain a single liquid phase. The sample was then melted and recast three to four times, so as to ensure its homogeneity. Next, approximately 10 g of alloy (cut and crushed into small pieces of ⩽50 μm) was wet-milled in a small batch with 0.5 g glycine (which serves as a lubricant, a surfactant, or a grain refiner) in 50 mℓ hexane in a steel bowl for 5 h, using a planetary mill machine (a Fritsch pulverisette) at a 300 rpm rotation speed, using hard steel balls with diameters of 2 mm and 4 mm (1:10 sample-ball ratio). Any excess Bi used here is assumed to inhibit separation of the Mn0.5Bi0.5 → Mn0.5Bi0.5−z + zBi, z ⩽ 0.05, during milling [20–23]. The resulting refined alloy powder (as milled, washed in hexane, and magnetically separated) was heated at Th = 573 K for tp =24 h, 48 h, 72 h and 96 h in Ar gas, in order to study how it reacts locally with free Bi and reforms small core–shell Mn0.5Bi0.5 –Bi crystallites.

A substitution reaction of Bi, diffused in a Mn0.5+xBi0.5−x series, as x → 0, causes a lattice expansion, which is then studied in terms of the XRD patterns of the critically annealed samples, recorded using a high resolution x-ray diffractometer (X'Pert PRO PANalytical), with a filtered Cu-Kα radiation of λ= 0.15410 nm wavelength, at an accelerating 40 kV voltage and a 40 mA electric current. A JEOL JEM-2100 HRTEM, operating at 200 kV, was used to provide HRTEM images, together with selected area electron diffraction (SAED), and lattice patterns of the samples as described in previous works [43, 44]. The magnetic properties of Ms, Hc, Mr, and K1 were studied based on M-H loops (over H = ±50 kOe fields) at selective 300 to 350 K temperatures, using a SQUID magnetometer. Thermomagnetic curves were studied by heating the samples in a temperature range from 300 to 750 K in a small H = 500 field Oe, using a vibrating sample magnetometer, which demonstrate how the lattice Bi-substitution leads to an improved TC point in the critically annealed core–shell Mn0.5+xBi0.5−x−Bi crystallites.

3. Results and discussion

3.1. Model reactions in Mn0.5 +x Bi0.5−x−Bi, x⩽ 0.05, crystallites

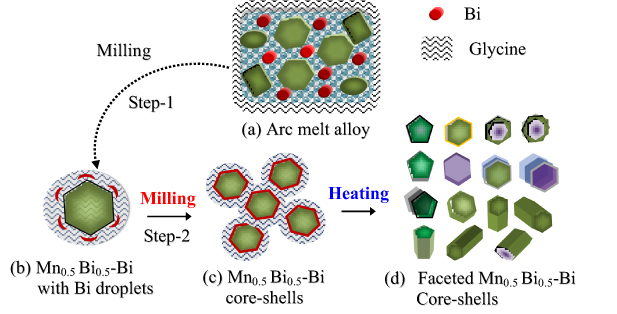

In view of our microscopic observations, wet-milling an alloy Mn0.5+xBi0.5−x−Bi, x ⩽ 0.05, with glycine is refined and dispersed via the glycine (step-1) into a fluid of hexane (liquid) in small Mn0.5+xBi0.5−x and Bi refined crystallites of refreshed surfaces, as shown in figure 1(a), in a model hierarchical structure. Glycine, a hydrocarbon NH2–CH2–COOH, binds over fresh metal surfaces as a 'surface passivation layer', which keeps them separated in such a way that they do not adjoin easily in the continued milling process employed in this experiment. Wihtout the use of glycine, refined alloy species will deform, expand and ultimately collapse into one another, resulting in a rather 'coarser structure' in thermochemical reactions where local heat is produced during the milling process. Soft ball-milling, however, is well controlled, allowing the Mn0.5Bi0.5−Bi sample to be finely refined into a nanostructure in the significant LTP-phase, where its magnetic properties may be tailored [20–22]. An inbuilt surface-layer divides the local heat over the refined alloy particles at an average temperature, which is not sufficient to disintegrate the refined Mn0.5Bi0.5 → Mn0.5Bi0.5−z + zBi alloy further in a peritectic reaction during continuous milling in hexane (a heat sink) in a closed container. This protects the highly coercive sample of surface-stabilized single magnetic domains. Further, in the proposed model, as shown in in figure 1(b), part of the excess Bi used here blends over the refined Mn0.5+xBi0.5−x to form small core–shell crystallites. On further milling (step 2), some of the Bi separates over the hot Mn0.5+xBi0.5−x facets in tiny droplets, which wet and mediate the alloy, growing slowly via wet facets, as x → 0, in a specific core–shell structure (see figure 1(c)) in local solid–liquid surface reactions.

Figure 1. A reaction module in (a) a near stoichiometric Mn0.5+xBi0.5−x−Bi alloy (x ⩽ 0.05) refined via wet-milling with glycine (step-1) in (b) Mn0.5−Bi0.5 crystallites with Bi-droplets and (c) Mn0.5Bi0.5−Bi core–shells (step 2), which grow in (d) facets at a critical temperature.

Download figure:

Standard image High-resolution imageSubsequent heating at Th = 573 K, just above Tm = 544 K of bulk bismuth, yields a refined sample of Mn0.5+xBi0.5−x−Bi, which grows preferentially (as shown in the XRD patterns described below) when free Bi slowly diffuses into the 'microscopic through channels' of the mobile vacancies (resulting from the milling process) via reactive wet-facets, in a lattice of small crystallites of Mn0.5+xBi0.5−x, x → 0. Presumably, a reverse reaction, Mn0.5Bi0.5 → Mn0.5Bi0.5−z + zBi, z ⩽ 0.02, occurs only beyond a critical growth on heating over a critical limit of tp = 72 h at 573 K, in such a way as to maintain its equilibrium over the residual Bi in the hybrid composite. Evidently, a refined sample maintains a larger degree of Bi solubility in the nanostructure. Further, a Mn-rich Mn0.55Bi0.45 alloy results in the separation of some Mn during extended milling, but this is readily reincorporated on heating at Th = 563 K [8, 25], due to the faster diffusivity of the smaller atoms. To obtain a single MnBi-LTP phase alloy is thus limited by the peritectic reaction occurring between Mn and Bi at around 535 K in which part of the Bi precipitates out (due to its lower Tm) in a supersaturated phase [12, 21]. Usefully, some of the free Bi binds to the Mn0.5+xBi0.5−x facets in such a way that its μℓ (≅−0.27 μB per atom) is set up opposite to μs in the core of the robust exchange-coupled core–shell magnet with modified magnetic properties. These can be formed in different model shapes, as shown in figure 1(d). Here, the excess Bi fulfils multiple roles in terms of its blending with Mn0.5+xBi0.5−x−Bi in small core–shell crystallites: (i) a grain refiner, (ii) a surfactant or a lubricant, (iii) a surface modifier, (iv) a reactive catalyst, and (v) an erosion resistance, in addition to readily allowing the tuning of lattice strain, twined boundaries, vacancies, and in turn the magnetic properties of the hybrid Mn0.5+xBi0.5−x−Bi, x ⩽ 0.05, structure, as shown below.

3.2. XRD view of effects of Bi diffused in Mn0.5 +x Bi0.5−x−Bi, x⩽ 0.05, crystallites

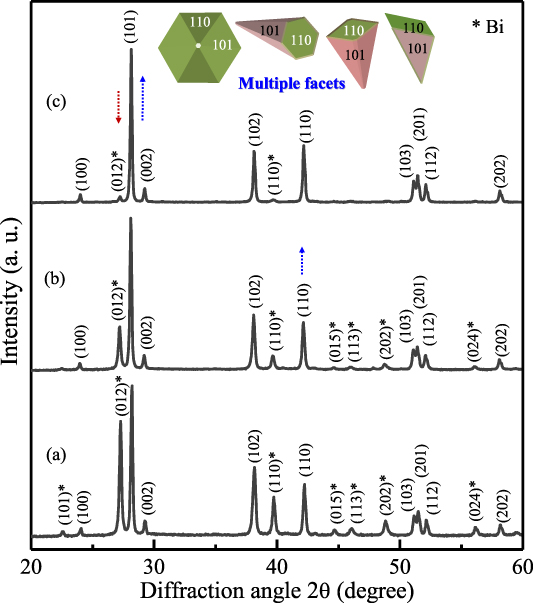

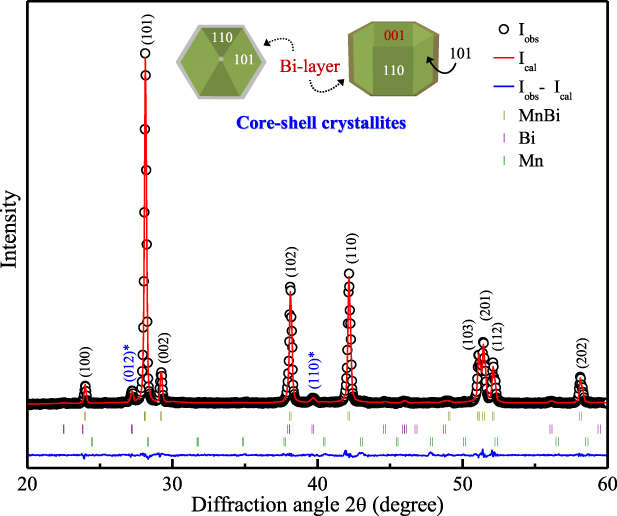

As anticipated, the master alloy of Mn0.5+xBi0.5−x−Bi, x ⩽ 0.05, contains XRD peaks indicative of free Bi, dispersed in a major Mn0.5+xBi0.5−x phase of small crystallites, in a Bi reinforced hybrid nanocomposite. When wet milled in powder form with glycine in a fluid medium (hexane), the refined Bi blends with the crystallites (alloy) and is finely dispersed into the phase boundaries in an intergranular phase due to thermally induced mechanochemical reactions. The refined powder thus contains a multiple structure of twins and defects (Bi vacancies, Mn/Bi interstitials, antisite disorders, etc), displaced in different orientations at the nanometer scale in a texture [40, 41]. This makes it a nontrivial precursor to the growth of tiny crystals in anisotropic shapes via thermal annealing. As a result, the XRD patterns in figures 2(a)–(c) reveal that a milled sample, heated at 573 K, slowly diffuses the Bi in a stable Mn0.5+xBi0.5−x, which ultimately results in a major phase (x → 0) of small core–shell crystallites over a tp = 72 h period. Thus, the sample has preferentially grown in multiple facets (see modules given in the inset), exhibiting enhanced (101) and (110) XRD peaks at the expense of the (102) peak. The lattice expansion, when Bi occupies regular sites in the crystallite, results in a shift in the XRD peaks over a larger interplanar spacing dhkl in the hexagonal Mn0.5+xBi0.5−x crystal structure (P63/mmc space group [45]). Figure 3 shows Retvield refined XRD peaks of the critically annealed alloy, tp = 96 h, owing to the presence of only a 2%–3% residual phase of free Bi (crystalline). A longer period of heating under these conditions results in a greater degree of Bi separation. No separate Mn peaks are visible since it has dissolved into a Bi-rich Mn0.5Bi0.5−Bi alloy, with lattice parameters a = 0.4289 nm and c = 0.6118 nm, a crystal density of ρ = 8.994 g cm−3), a lattice volume Vc = 0.0975 nm3, and D = 35 nm. Larger values of a = 0.4290 nm and c = 0.6130 nm (ρ = 8.971 g cm−3) prevail in bulk Mn0.5Bi0.5 [8, 45]. Small core–shell Mn0.5Bi0.5−Bi crystallites adopt a larger ρ-value as a consequence of an inbuilt compressive surface layer, and free Bi occupying its vacancies, as described below.

Figure 2. XRD patterns in small Mn0.5Bi0.5−Bi crystallites grow in facets (modules shown in inset) in a diffusion reaction with liquid Bi at 573 K for (a) 24 h, (b) 72 h, and (c) 96 h, where the (110) peak is successively grown over the (102) peak.

Download figure:

Standard image High-resolution imageFigure 3. Observed (points) and Retvield refined (line) XRD patterns for Mn0.5Bi0.5−Bi crystallites (annealed at 573 K for 96 h) of a model core–shell (shown in the inset). Their difference is marked along with positions (lines) of Mn0.5Bi0.5, Bi and Mn peaks at the bottom.

Download figure:

Standard image High-resolution imageIn the model reaction, free Bi at 573 K in the mixed Mn0.5+xBi0.5−x−Bi alloy diffuses via deep interfaces, travels and fills the vacancies in the Mn0.5+xBi0.5−x, x → 0, in a pool, resulting in the tailored XRD peaks of the annealed samples. Thus, the most intense (101) XRD peak (normalized intensity I101 = 1.0) in figure 4 has slowly grown at the expense of a major (012)* peak of the free Bi, whereby it first shifts over a larger diffraction angle 2θ (smaller d101), tp ⩽ 24 h, before reverting to lower 2θ-values on further heating, tp ⩽ 72 h. With reference to the second (102) and third (110) most intense peaks, with intensities of I102 = 0.45 and I110 = 0.35 for the starting sample, I110 has increased to 0.41, while I102 has reduced to 0.34, based on heating over a period of 96 h. Larger d101 and d* 012 values exist due to the presence of significant Bi vacancies, reported to be as much as 8% for a rapidly cooled Mn0.5Bi0.5 alloy [12]. The vacancies appear to be filled in a recurring lattice during the course of heating the sample, where a solid–liquid pool tunnels hot Bi atoms diffuse in this example of vacancy-induced shear bands of 'microscopic through channels'. As a result, it acquires an anisotropic growth of small crystallites. Any excess Bi used here not only diffuses via reactive facets and fills-up Bi sites in a growing crystal lattice in an Mn0.5Bi0.5−Bi pool, but also prevents the Mn from precipitating over by raising its solubility in a hybrid nanostructure at this temperature. As a result, after 96 h heating, only a small trace of the (012)* Bi peak remains, compressed to d*012 = 0.3275 nm, along with d101 = 0.3170 nm, due to the compressive effect of the small core–shell Mn0.5Bi0.5−Bi crystallites. Presumably, this is the thin inbuilt Bi surface layer, tightly bound over the Mn0.5Bi0.5 facets so as to compress the lattice in a conjoint core–shell structure. Other XRD peaks (102), (110)*, and (110) in figure 4 have reordered congruently at the perspective 2θ-values. The (110)* Bi-peak gradually loses its intensity as the free Bi migrates to Mn0.5Bi0.5, growing in an anisotropic (101)/(110) crystal texture.

Figure 4. XRD peaks shifting over lower 2θ-values as Bi dissolves into the core on heating (a) a sample containing Mn0.5+xBi0.5−x−Bi (x ⩽ 0.05) at 573 K in a model (at the bottom) core–shell structure for (b) 24 h, (c) 48 h, (d) 72 h, and (e) 96 h. This process reverts (e) due to prolonged heating.

Download figure:

Standard image High-resolution imageThe microscopic model proposed in figure 4 (bottom) describes a possible pathway for the free Bi whereby local melting causes it to diffuse, travel, and drive a surface reaction in a pool of Mn0.5+xBi0.5−x−Bi (on heating at 573 K) in order to fill the Bi sites in the Mn0.5+xBi0.5−x, x → 0, lattice. Conversely, as a supersaturated sample of Mn0.5Bi0.5−Bi obtains a critical D ⩾ 35 nm size (table 1) due to a longer period of heating, it precipitates out the excess Bi in a reverse reaction, forming an Mn-rich Mn0.5Bi0.5−z + zBi, z ⩽ 0.05, alloy of small core–shell crystallites. A high yield LTP-MnBi alloy, made using different methods, thus always ends with a residual 2%–5% Bi [19–29]. An excess of Mn(z), as per a smaller atomic radius of 0.130 nm as compared with Bi at 0.182 nm [46], results in a 0.23% lower Vc in terms of its saturated value at tp ∼ 72 h. As shown in the analysis of the XRD peak broadening in the Williamson–Hall plot [47], the core–shell exhibits a lattice strain of γ = 0.17–0.22%, which barely decreases even in bigger crystallites, D = 38 nm (27 nm at tp ∼ 0), grown at 573 K over tp → 96 h (table 1). This may be ascribed to the shell storing the strain in the small core–shell crystallites. Figure 5 depicts (a) a crystal Mn0.5Bi0.5 unit cell of (b) Mn and Bi atoms ordered in terms of magnetic moments of (c) valence electrons, with (d) model facets as observed in its XRD pattern. In this case, the x-ray beam imposes a sample on its (101) facet at an angle, as shown in figure 5(e), so as to exhibit XRD with its most intense (101) peak, though it also shares the increased anisotropic XRD intensities of conjoint facets (002), (102), (110), or (201) proportionally to their cross-sections, as can be observed here for a sample of a (101) crystal texture.

Figure 5. (a) A model crystal Mn0.5Bi0.5 unit cell distributing (b) Mn and Bi atoms of magnetic moments of (c) valence subshells, (d) conjoint facets, and (e) recurring XRD in a (101) crystal texture grown with (110), (102), and (201) facets.

Download figure:

Standard image High-resolution imageTable 1. Effects of thermal annealing on structural parameters in relation to the stoichiometry of an alloy of Mn0.5+xBi0.5−x−Bi dissolving free Bi and growing small crystallites at a critical temperature.

| Lattice parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Annealing time (h) a | x–value | a (nm) | c (nm) | c/a | Vc (nm3) | ρc (g cm−3) | D (nm) | γ (%) |

| 0 | 0.051 | 0.4290 | 0.6119 | 1.4263 | 0.0975 | 8.452 | 27 | 0.199 |

| 24 | 0.014 | 0.4281 | 0.6108 | 1.4268 | 0.0969 | 8.894 | 32 | 0.210 |

| 48 | 0.004 | 0.4286 | 0.6114 | 1.4265 | 0.0973 | 8.971 | 33 | 0.215 |

| 72 | 0.000 | 0.4289 | 0.6118 | 1.4264 | 0.0975 | 8.994 | 35 | 0.192 |

| 96 | 0.005 | 0.4285 | 0.6113 | 1.4266 | 0.0972 | 8.961 | 38 | 0.174 |

a At a critical 573 K temperature. x-value is estimated as per the XRD and TC values.

3.3. HRTEM images of Mn0.5 +x Bi0.5−x−Bi, x⩽ 0.05, core–shell crystallites

The HRTEM images shown below, studied along with the SAED patterns, clearly display how the master alloy Mn0.5+xBi0.5−x–Bi, x ⩽ 0.05, has grown in multiple facets of small core–shell crystallites after heating at 573 K, and that the free Bi has slowly diffused therein via a solid–liquid interface in small pools at a length scale of depletion of a few nanometers. Multiple twins displaced in different orientations have previously been reported in shape memory alloys of nanostructures [40, 41]. A given alloy thus creates a pattern of multiple martensite/austenite phases. A recurring lattice strain (a vital variant), in Bi diffused into free sites, dictates nontrivial growth of the unified structure of the texture, as described above in terms of the XRD patterns of the annealed samples. For example, well-defined core–shell crystallites are shown in HRTEM images at different scales in figures 6(a)–(c) for the wet-milled alloy in glycine formulated in this work. Uniquely, these are grown in a specific shape of fullerene C60 like balls of multiple facets (primarily pentagons, hexagons, octagons, or dodecagons), with widths in cross-section of W = 40 − 100, bounding a thin peripheral surface layer of θ ≅ 1.9 nm thickness. Their corners appear to be bent inwards, as though tightly reinforcing the surface-to-volume ratio in a rigid core–shell structure, with a fairly sharp size distribution, in that almost 80% of the sample exhibits an average width of W = 60 nm. A typical SAED pattern in figure 6(d) reveals that the crystallite has grown systematically in (101) regular lattice arrays at a regular separation of d101 = 0.3215 nm. A few twins (Ts) of white spots are observed at off lattice points (weaker intensities) indicating the presence of a few vacancies and/or interstitials in the regular lattice of a single Mn0.5+xBi0.5−x, x ⩽ 0.05, nanocrystal. The arrow marks how lattice arrays twisting on a twin boundary are inbuilt at the facets in a core–shell structure.

Figure 6. (a) HRTEM images of Mn0.5+xBi0.5−x−Bi (x ⩽ 0.05) core–shell crystallites (having been wet milled) grown in (b) a round shape of (c) facets, (d) SEAD from (c) a crystallite of (e) lattice images, (f) model building blocks and (g) derivatives. T: twin, and TB: twin boundary.

Download figure:

Standard image High-resolution imageFigure 6(e) displays an HRTEM image of three consecutive edges, A, B, and C, of a cross-section (a polygon) of a Mn0.5+xBi0.5−x−Bi core–shell crystallite, showing how it varies in terms of (i) atomic stacking at edges, (ii) internal angles, and (iii) surface layers on its different facets. A single surface strip (whitish) is marked on facet A, where δ = 1.90 nm thickness, while 3 to 4 substrips are split up in a specific pattern on facet B, where δ = 1.95 nm, as per the topotactic structures and stacking energies of the surface atoms. Moreover, edges A and B of the internal angle where φ = 140° are duly stretched over the subsequent B and C edges of φ = 145° in a markedly truncated dodecagon, as given in figure 6(f). Finally, a thin polygon, primarily grown with (101) facets, reveals (101) lattice arrays, where d101 = 0.3215 nm, in figure 6(e), in the form of a fullerene-like shape, as shown in close-up in the inset. A Bi-diffusion reaction, proceeding undisrupted at 573 K, results in a regular Mn0.5+xBi0.5−x, x → 0, growing slowly (without deforming into a twin) in a presumed 'microscopic through channel' over its reacting facets, as illustrated in the model in figure 6(g), in a (101) crystal texture.

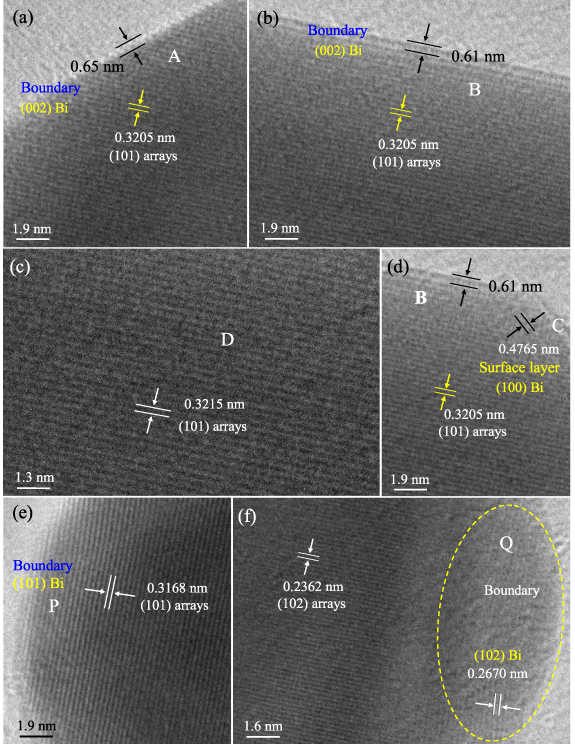

A further closer view of the lattice images of a core–shell crystallite, e.g. PQ in figure 6(e), reproduced in figure 7, produces futher insights into its internal structure, surface topology, and peripheral surface boundaries. A distinct boundary layer (whitish), where δ = 0.65 nm, is marked on facet A, which looks to be rather darker on facet B, where δ = 0.61 nm, possibly due to a (002) stacking of Bi atoms (a rhombohedral structure) in this module, i.e. stretched over a bulk d002 = 0.5930 nm Bi-value [45]. Presumably, this interlocks the (101) lattice arrays of a single crystallite enclosed inside it like a cage, leading to slight compression near the surfaces, so that d101 = 0.3205 nm in figures 7(a) and (b), over the inner zone D in figure 7(c), d101 = 0.3215 nm, due to the tightly binding surface layer (like a belt) of a closely exchange-coupled core–shell structure. In a counterpart effect, characteristically diffuse d100 = 0.4765 nm Bi-arrays are marked on the (101) arrays on the BC edges in figure 7(d). Furthermore, the (101) lattice arrays are more converged, so that d101 = 0.3168 nm, near surface P in sample PQ in figure 7(e), containing multiple (102) lattice arrays, where d102 = 0. 2362 nm, and a topotactic Bi-surface layer (d102 = 0.2670 nm), as marked in boundary Q in figure 7(f). Moreover, on heating at 573 K, one core–shell Mn0.5+xBi0.5−x, x → 0, grows in a 3D-prism on a basic building block of a 2D-polygon of atomic arrays. This appears with a hexagonal-shaped cross section (20–80 nm long and W = 20–60 nm) in the HRTEM images as viewed at different scales, shown in figures 8(a)–(c), for a sample heated for 48 h at 573 K.

Figure 7. Surface tuned lattice images (a → f) in successive parts of a core–shell Mn0.5+xBi0.5−x−Bi (x ⩽ 0.05) crystallite (of figure 6(e)) with inbuilt Bi-surface layer(s).

Download figure:

Standard image High-resolution imageFigure 8. (a), (b), (c) HRTEM images of Mn0.5Bi0.5−Bi crystallites grown (via heating a milled sample at 573 K for 48 h) in critical shapes (projected at different scales), (d) SEAD from a crystallite of (e) lattice images, and (f) modules grown in (g) a density gradient.

Download figure:

Standard image High-resolution imageThe above HRTEM images show an example of a surface strained sample that exhibits SAED spots in rings, as shown in figure 8(d), from its (101), (002), (102) and (110) crystallographic planes, with dhkl (radii) of 0.3170, 0.3050, 0.2445, and 0.2165 nm, respectively. Presumably, the d012 Bi-surface layer shares the bright ring (0.3295 nm radius) near the centre of the SAED pattern in a core–shell sample. Moreover, (101) lattice images (d101 = 0.3170 nm) obtained from the rectangular facet of a polygonal prism, as shown in figure 8(e), superpose over broad interference fringes (of 0.65 nm and 1.05 nm separations in regions-1, 2) due to electron beams interfering in reflections from successively inbuilt surface layers in the sample. Similar interference fringes had been observed in C-sp2 coated spinel oxides [11, 44] and gold [48] core–shell nanostructures. Figure 8(f) compiles the different modules of anisotropic shapes of core–shell crystallites derived from building blocks of a 2D-pattern of atomic arrays in a 3D-hexagonal lattice. In view of the observed lattice pattern of atoms, a model core–shell crystallite in figure 8(g) contains three microscopic regimes (i) an average atomic density in a deep core below its surfaces, (ii) a compressed atomic density near interfaces, and (iii) a stretched surface layer in a hybrid structure. All three factors collectively tailor the magnetic properties in a core–shell structure, as discussed below.

3.4. Magnetic properties of Mn0.5 +x Bi0.5−x−Bi, x⩽ 0.05, core–shell crystallites

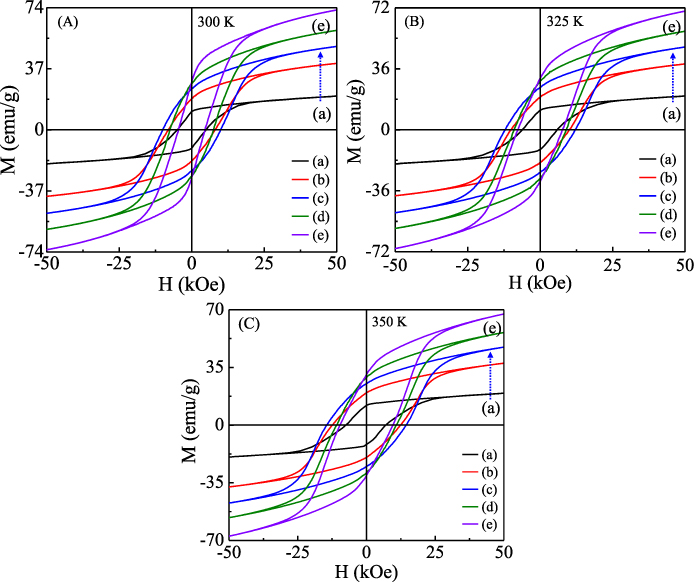

An annealed alloy Mn0.5+xBi0.5−x−Bi, grown in a (101) texture, and comprising small core-shell crystallites filled with Bi sites (x → 0) , exhibits markedly improved Ms, Mr, Hc, and K1 values in a wider M-H hysteresis loop at room temperature. For example, figures 9(a)–(e) compares M-H loops, measured over H ⩽ 50 kOe at temperatures of 300, 325, and 350 K , for samples annealed at 573 K for 0, 24, 48, 72, and 96 h, respectively. Magnetization (M) does not saturate below a specific level of H fields, in lieu of a higher Ha = 2K1/Ms > 50 kOe in these samples of randomly oriented single domains. In this case, the Ms is stipulated by extrapolating M over high-field susceptibility (χm), in accordance with the well-known law relating to saturation [49]:

Figure 9. M-H loops measured at (A) 300 K, (B) 325 K, and (C) 350 K from (a) a master alloy Mn0.5+xBi0.5−x−Bi (x ⩽ 0.05) annealed at 573 K for (b) 24 h, (c) 48 h, (d) 72 h, and (e) 96 h. The arrow marks magnetization increases where free Bi is incorporated in the exchange-coupled core–shell magnetic structure of small crystallites.

Download figure:

Standard image High-resolution imageHere, H → ∞, a nonlinear χm(H) extends over H-induced rotations of unsaturated spins in superparamagnetic (SPM), paramagnetic (PM), or antiferromagnetic (AFM) species along a net induced M-value. As given in table 2, a low value of Ms = 20.5 emu g−1 obtained at 300 K in the master alloy has increased to 72.5 emu g−1 for a sample annealed for 96 h at 573 K. A marginally lower 70.0 emu g−1 is measured at 325 K, and 67.4 emu g−1 is recorded at 350 K, with a small thermal coefficient, β = (∂Ms/∂T)Ms −1 ≅ −0.14% K−1, in terms of heat induced spin relaxations. These are better Ms values in comparison to other reported high Hc values (compared in table 3) achieved using refined alloys of small crystallites [9, 26,27,28–31], which usually lose Ms on canted (or SPM) surface spins.

Table 2. Effects of thermal annealing on magnetic parameters of a Mn0.5+xBi0.5−x−Bi alloy, grown in small core-shell crystallites at the expense of free Bi at a given critical temperature.

| Ms (emu g−1) | Hc (kOe) | K1 (107 erg cm−3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Annealing time (h) a | 300 (K) | 325 (K) | 350 (K) | 300 (K) | 325 (K) | 350 (K) | 300 (K) | 325 (K) | 350 (K) | TC (K) | ||

| 0 | 20.5 | 20.1 | 19.4 | 5.010 | 6.155 | 7.535 | 0.9 | 1.0 | 1.2 | 600.5 | ||

| 24 | 40.3 | 38.9 | 37.5 | 8.015 | 10.150 | 12.505 | 3.4 | 3.8 | 4.2 | 630.0 | ||

| 48 | 50.5 | 48.9 | 47.4 | 9.850 | 12.065 | 14.435 | 4.2 | 4.7 | 5.2 | 638.5 | ||

| 72 | 60.3 | 58.2 | 56.2 | 7.015 | 8.950 | 10.850 | 5.1 | 5.7 | 6.3 | 641.5 | ||

| 96 | 72.5 | 70.0 | 67.4 | 4.345 | 7.605 | 9.565 | 6.3 | 7.1 | 8.0 | 637.5 | ||

Table 3. Typical Mn0.5+xBi0.5−x (x ⩽ 0.05) alloys prepared via different routine methods, and their optimized functional magnetic properties at room temperature.

| Compositions and Preparation methods | Ms (emu g−1) | Hc (kOe) | K1 (107erg cm−3) | TC (K) | Ref. |

|---|---|---|---|---|---|

| 1. Arc melt (annealed): Mn0.51Bi0.49 bulk Mn0.55Bi0.45 bulk | 58.2 74.0 | <3.0 ∼3.0 | — — | — 628 | Cui et al [8] |

| 2. Hot-compacted Mn0.55Bi0.45 powder (arc melt on annealed/ball milled) | 72.5 | 0.75 | 1.80 | — | Muralidhar et al [13] |

| 3. Arc melt Mn0.5Bi0.5 (annealed) followed by ball milled | 66.6 10.7 | 0.85 14.65 | — — | 635 — | Li et al [23] |

| 4. Mn0.55Bi0.45 nanosheets (ingots annealed/wet milled) | ⩾37.0 | 14.3 | —- | —- | Liu et al [9] |

| 5. Melt-spun Mn0.5Bi0.5 ribbons (annealed) | 55.0 | 3.70 | — | 630 | Saito et al [24] |

| 6. Melt-spun ribbons Mn0.54Bi0.46 (annealed) (field aligned powder) | 75.0 67.5 | 0.40 11.0 | 1.1 | 620 | Kharel et al [33] |

| Mn0.47Hf0.03Bi0.50 (annealed) (field aligned powder) | 69.7 62.7 | 2.40 13.0 | 1.0 | 625 | Kharel et al [33] |

| 7. Mn0.5Bi0.5 nanoparticles (spark erosion) | 69.0 | 10.0 | — | — | Naguyen et al [27] |

| 8. Mn0.5Bi0.5 nanopowder (metal-redox synthesis) | 49.0 | 15.0 | — | — | Kirkeminde et al [29] |

| 9. Mn0.55Bi0.45 sintered powder (powder metallurgy) | 54.9 | 8.0 | — | — | Si et al [30] |

| 10. Mn0.5Bi0.5-Bi nanoparticles (mechanochemical process) | 22.0 | 16.3 | — | — | Rao et al [31] |

| 11. Mn0.5Bi0.5−Bi core–shells a (arc melt on wet milled & annealed) | (a) 50.5 | 9.850 | 4.2 | 638.5 | Present work |

| (b) 60.3 | 7.015 | 5.1 | 641.5 | ||

| (c) 72.5 | 4.345 | 6.3 | 637.5 |

a Wet-milled powder annealed for (a) 48 h, (b) 72 h, and (c) 96 h at 573 K.

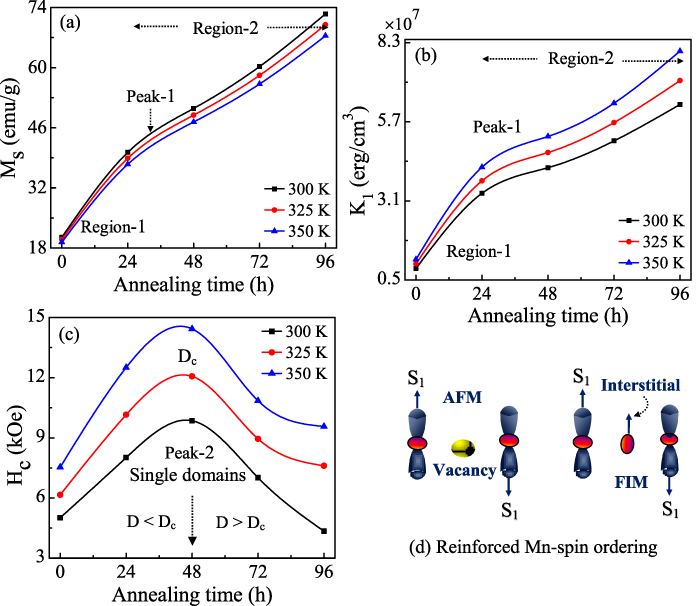

As plotted in figure 10(a), Ms occurs in two microscopic steps, 1 and 2, as the Mn0.5+xBi0.5−x−Bi alloy is heated over tp at 573 K. In region 1, a peak 1 evolves at tp ∼ 24 h, superposing over a linearly growing Ms in region 2 into a denser alloy, where ρc = 8.994 g cm−3. In addition, K1 = 0.9 × 107erg cm−3 has peaked rapidly at this point in figure 10(b), stiffly growing over a given tp of a critical 6.3 × 107erg cm−3 value at tp ∼ 96 h. Hc is enhanced to 9.850 kOe over 5.010 kOe (at tp ∼ 0) in a broad peak 2 in figure 10(c) for the sample of critical single domains (size Dc = D ≅ 33 nm) at a critical tp ∼ 48 h. It falls to 4.345 kOe in mutidomains at later tp. The Hc is progressively enhanced in peak 2, measured at higher 325 K and 350 K temperatures, with a positive thermal coefficient, (∂Hc/∂T) Hc −1 ≅ 0.93% K−1. An Hc value as high as 14.435 kOe is thus obtained at 350 K in critical single domains with K1 = 5.2 × 107erg cm−3. Here, Hc falls on either side of Dc ; where D < Dc, this is due to the growth of SPM species (region 1), and where D > Dc, this is due to the growth of multidomains (region 2) in a wide distribution of D-values. Other details of magnetic parameters obtained at three temperatures for the annealed alloys of model D-values of the core-shell crystallites are given in table 2.

Figure 10. Effects of Mn0.5+xBi0.5−x−Bi incorporating free Bi and grown in a (101) texture of small core–shell crystallites, indicating its final (a) Ms, (b) K1 and (c) Hc when annealed at 573 K, with (d) a model vacancy/interstitial reinforced Mn-spin S1 ordering.

Download figure:

Standard image High-resolution imageNext, we review the mechanism by which of Ms is promoted as Bi diffuses in a Bi deficient Mn0.5+xBi0.5–x, x ⩽ 0.05, sample (having been annealed at 573 K), filling the available Bi vacancies, and replacing some Mn at antisites till x → 0. In contrast, some Bi sites are exchanged with Mn atoms in an Mn doped off-stoichiometric alloy of an antisite lattice disorder, which not hampers only net Ms, but also other functional magnetic properties. Thus, a case where two successive Mn atoms either displace via a vacancy, or an antisite is filled by a Mn atom, would result in an AFM scheme of spins (a so-called a 'spin-blister') in place of an FM order, as would usually be found in pure Mn or its many alloys [7, 35]. As a result, the net Ms decreases, as described via the spin model shown in figure 10(d), due to the shorter Mn–Mn distance, as is clearly reflected in the (101) XRD peak in the sample annealed for 24 h at 573 K in figure 4(b). The value recovers as blisters dissolve in the course of further annealing. A significant value, μℓ > 0, shares the p-d hybridization occurring between Bi and Mn atoms in an exchange-coupled magnet. Further, Mn-d5 and Bi-p3 spins, when ordered in opposition at alternate sites, form a ferrimagnetic (FIM) structure with a strong Mn-Bi-Mn superexchange interaction of p-d electrons, as described in figure 5(c). For example, N(sp3), part of the same VA group as Bi, shares a significant μs when bonded to C-sp2 [50, 51]. A derivative C3NH0.135 exhibits the wide M-H loop, with Ms = 35.2 emu g−1 (at 1.8 K) and TC = 96 K, of a semiconductor magnet [51]. The Mn0.5+xBi0.5–x, x → 0, alloy is therefore shown to hold a net spin-magnetic moment per formula unit:

where μs1 ≡ g1{S1(S1 + 1)}½ ≅ 5.92 μB, μs2 ≡ g2{S2(S2 + 1)}½ ≅ 3.87 μB, g1 ≅ g2 ∼ 2.0 denotes the Lande g-factor, and ϕ denotes the angle between the S1 = 5/2 and S2 = 3/2 spins of Mn and Bi atoms, respectively. As ϕ → 180°, it tunes a minimum μs(t) ≅ 1.03 μB, i.e. still nearly twice the value of nickel (Ms = 54.4 emu g−1). Generally, μs2 is quenched over a large atomic Bi space, leaving behind a net μs(t) ≅ 3.42 μB (72.5 emu g−1), as observed here. A huge μs(t) ≅ 4.90 μB (or 103.7 emu g−1) would incur per formula unit in μs1 and μs2 set up in parallel. The variants ϕ and μs2 can this be seen to control a wide range of Ms values, usually 22 to 81 emu g−1 at 295 K [6–10, 14, 26,27,28–31] in the Mn0.5+xBi0.5–x, x → 0, sample, as per its hierarchical structure of spins for a texture of small crystallites. Accordingly, there is scope for the potential scaling-up of MS (and other magnetic properties) on induced μs2 in surface-modified Mn0.5Bi0.5−x (x ⩽ 0.05), with N-sp3 and C-sp2 spins of light atoms.

In a marked effect of Bi → Mn substitution, the TC point is gradually enhanced in thermomagnetic curves (measured at a bias field, H = 500 Oe) in figures 11(A) and (B) relating to Mn0.5+xBi0.5−x−Bi alloys annealed for tp ⩽ 72 h at 573 K. As anticipated, this confers a composition-dependent TC, as a result of the enhanced Mn-Bi-Mn exchange interaction [14, 33], which is maximized in terms of stoichiometry as x → 0. As large a value as TC = 641.5 K (x ∼ 0) is obtained above 600.5 K in the initial (x ∼ 0.05) after tp ∼ 72 h. Here, free Mn, if it precipitates at all over a supersaturated alloy, combines with any mobile Bi in the vicinity, forming a stable Mn0.5Bi0.5−Bi phase of small core–shell crystallites. A derivative of these curves (figure 11(C)) displays a fairly sharp peak (ΔTC = 8–20 K width) of a precisely determined value. Here, a wider signal, ΔTC ≅ 20 K, extends in Bi vacancies and/or antisite Mn order in a wide band of density of states over its average value. An enhanced TC = 641.5 K, over a bulk Mn0.5Bi0.5 value of 628 K [6–8], confers small core–shell crystallites which promote a coupled magnetic and structural LTP → HTP transition. A satellite TC1 peak, displaced in HTP, converts to a PM state at 645.5 K (figure 11(C)) in a sample heated for up to 96 h, where some Bi segregates into phase boundaries. As expected, well below TC, the surface magnetism decays in two overlapping micromagnetic regimes, 1 and 2, over two distinct types of exchange-coupled spins in the small core–shell crystallites.

Figure 11. (A) Thermomagnetic curves (at H = 500 Oe) with (B) a magnified view of TC region exhibits a peak in (C) the derivatives over temperatures, and (D) variation of TC on annealing Mn0.5+xBi0.5−x−Bi at 573 K for (a) 0, (b) 24, (c) 48, (d) 72, and (e) 96 h.

Download figure:

Standard image High-resolution imageAt near stoichiometry, Mn0.5+xBi0.5−x, x ⩽ 0.05, the enhanced FM interaction, in relation to free Bi, diffused to (x → 0) and replaces Mn placed on the antisites in a core–shell crystallite, describing a sharply enhanced TC(x) in a model DFT relation:

with

where Ω12(x) is a module describing an exchange interaction between the S1 and S2 sites of spins, and 'p' is an exponent which modulates them in a recurring variant of x-value. As given in table 2, a normalized Ω12(0) = 1.0 with a model q = 1/3 reproduces an observed TC = 600.3 K using x = 0.051 (in the initial alloy) and a model p = 1/3 on TC(0) ≡ 641.5 K, within a deviation ⩽0.4 K. The same model parameters satisfactorily reproduce an intermediate TC ≅ 629.7 K at x = 0.014, as observed in the 24 h annealed alloy, or TC ≅ 638.1 K at x = 0.004 in an alloy annealed for 48 h at 573 K. This model duly accounts for and describes an antisite effect of Mn-d5 spins on TC in this alloy of small core–shell crystallites. In figure 11(D), the TC varies in two maxima in two microscopic regions, 1 and 2, of two overlapping parabolic paths over tp, as any free Bi in the vicinity diffuses into a stable Mn0.5+xBi0.5−x phase. The antisite Mn present in region 1 reorders via vacancies in region 2. A decrease in TC after a critical 541.5 K value confers a supersaturated alloy, releasing Bi in any further annealing. In general, a module of the magnetic TC signal in equation (3), which increases the heat, ΔQ = ΔSTC, on disordered spins in an FM → PM transition (with a change of entropy ΔS), can be further extended by formulating its impacts on coupled lattice-expansion, magnetocalory and magnetostriction over the transition, and their associated applications.

4. Conclusions

In this paper, a mixed alloy, Mn0.5+xBi0.5−x−Bi, x ⩽ 0.05, is presented, using a method designed to tailor a core–shell magnet comprising small crystallites of D = 27–38 nm size, with useful magnetic properties for high-energy magnets and devices. A key factor is that spins may be pinned down at the surfaces in a 'spin barrier layer' and it is therefor possible to monitor the dynamic features of single domains. As such, the wet milled powder (of a bulk alloy) owes its lower x-ray density ρ = 8.452 g cm−3 to the presence of a partial Mn → Bi antisite substitution, a few Bi vacancies, and small twins. On annealing at a critical temperature of 573 K, the alloy sincorporates free Bi to fill any vacancies (resulting in an increased ρ = 8.894 g cm−3, based on a 24 h annealing period), and to replace part of the antisite Mn in a Mn0.5+xBi0.5−x, x → 0, stoichiometry, with a maximized ρ = 8.994 g cm−3 based on a critical 72 h annealing period. In a model reaction, when free Bi locally melts (Tm = 544 K) at an annealing temperature of 573 K, it percolates a diffusion reaction, leading to the growth of small crystallites in anisotropic facets in a (101) texture. Any excess Mn precipitated by a saturated phase reacts with any free Bi present nearby, and reforms into stable Mn0.5Bi0.5 small core-shell crystallites, with a thin Bi surface layer (1–2 nm thickness). As a stable Mn0.5+xBi0.5−x, x → 0, occurs, magnetization is duly recovered in a wide M-H loop at room temperature. In a micromagnetic model, Bi-p3 interlocks Mn-d5 (of unpaired spins) in a hybrid spring magnet on hybridized p-d electrons, which advances its thermal stability and anisotropic magnetic properties, as observed for the annealed samples. In general, Bi-p3 spins occur in opposition to Mn-d5 spins in a ferrimagnet, Mn0.5+xBi0.5−x, x ⩽ 0.05, which successfully describes its highly variable Ms = 22 to 81 emu g−1, as observed at 295 K when prepared using different routine methods [14, 28–31]. Any excess Mn clots in an AFM blister (i.e. it forms a twin in a crystal lattice), decreasing the average FM properties. At room temperature, a maximum magnetization 72.5 emu g−1 (20.5 emu g−1 at x ∼ 0.05) is observed, with an order of enhanced K1 = 6.3 × 107 erg cm−3, with TC = 641.5 K (600.5 K at x ∼ 0.05) in the annealed core–shell Mn0.5Bi0.5−Bi crystallites. A maximum Hc = 9.850 kOe (14.435 kOe at 350 K) is achieved in a sample of the critical single domains (D ∼ 33 nm). These results indicate the potential for finely tuning magnetic properties by means of vacancies, multiple twins, and/or Mn antisites in small core–shell Mn0.5Bi0.5−Bi crystallites, which may prove useful in the fabrication of small magnets, tools, and other devices.

Acknowledgments

The authors wish to express their gratitude to Dr Alok Banerjee, UGC-DAE Consortium for Scientific Research Indore, India, for providing some of the magnetic measurements. This research has been financially supported by the MHRD, Government of India.

Conflict of interest

The authors declare no conflict of interest, financial or otherwise.