Abstract

Background, aim and scope

This paper presents a life cycle assessment (LCA) of the manufacturing process of crystal glass products in order to evaluate the potential environmental impacts due to a crystalware company located in Colle di Val d’Elsa, Siena (Italy). Since there is not any published research specifically focussed on crystal production to our knowledge, outcomes from this study would represent a first documented evidence gathered from an LCA of crystal glass products. Once a detailed description of the production process was provided, different categories of impacts were assessed and analysed. Outcomes allowed us to identify ‘weak points’ in the production process and propose possible solutions for decreasing the risk of negative effects on the environment.

Materials and methods

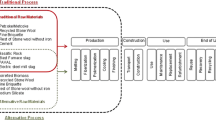

According to the LCA methodology, the whole life cycle of crystal glass was structured into four primary phases—raw materials acquisition, crystal glass manufacturing, product utilisation and final disposal—each of which includes a set of sub-processes. Through an accurate life cycle inventory, primary data, relative to the year 2006, were elaborated through the EDIP database. The calculation of impacts was aided by GaBi4 software with reference to a functional unit corresponding to 1 kg of crystal glass products. Relative to the CML2001 problem-oriented approach, a set of impact categories was used for the classification and characterisation of the life cycle impact assessment. Potential category indicators were finally accounted for and normalised in accordance with the CML Western Europe method.

Results

The following ten impact categories were assessed: (1) depletion of abiotic resources, (2) acidification, (3) eutrophication, (4–6) ecotoxicity (marine and freshwater aquatic as well as terrestrial, respectively), (7) climate change (greenhouse effect), (8) human toxicity, (9) stratospheric ozone depletion and (10) photo-oxidant formation. Results showed that among the main phases, crystal glass manufacturing is the one with the highest environmental impact and emissions to air, mainly due to an intensive use of energy and materials. In particular, some sub-processes within the manufacturing stage, such as melting in furnaces, acid polishing, cutting and forming, were found to hold a high responsibility for most of the environmental effects. The main effects depend on CO2, NOx and SO2 emissions, heavy metals emissions and use of non-renewable resources. In particular, the latter is due to the processes of extraction, refining, transport and use of fuels such as natural gas.

Discussion

Results were analysed relative to each of the main processes involved in the crystal glass life cycle and critical points were investigated in order to inform the administrators of the crystalware company and address future choices towards a more sustainable production. Some technical solutions were proposed in order to improve environmental performances. Impacts due to the use of lead in the mixture were widely treated in literature and briefly discussed here.

Conclusions

An accurate energy and material flow inventory allowed us to assess the potential environmental impacts of the crystal glass production in Colle Val d’Elsa, including the effects of processes occurring within the industrial plant and those due to the import of products and services from outside. Through the case study, we aimed to provide an exhaustive description of the main steps in the process and clear results relative to different impact categories. Outcomes showed that some procedures could be implemented in order to decrease these impacts. The use of lead is an irreplaceable characteristic of crystal products, but also a critical point to deal with. Nevertheless, the high quality of man-made crystal products makes the use of lead acceptable. The LCA of crystal glass products presented in this paper provided an accurate description of processes and procedures that can mirror a traditional production in a broader sense. This paper can therefore represent a valuable reference for future studies on crystal glass production processes.

Recommendations and perspectives

The LCA method was performed for identifying critical aspects in the production process from an energetic and environmental viewpoint and was useful for constructing a model of the crystal glass production in Colle di Val d’Elsa. This can be a starting point for processing an environmental product declaration.

Similar content being viewed by others

Notes

2006/690/EC: Commission Decision of 12 October 2006 amending, for the purposes of adapting to technical progress, the Annex to Directive 2002/95/EC of the European Parliament and of the Council as regards exemptions for applications of lead in crystal glass.

Actuation of directive 2003/87/EC and 2004/101/CE of the European Parliament and of the Council establishing a scheme for greenhouse gas emission allowance trading within the Community and amending Council Directive 96/61/EC. Schema di Piano Nazionale d’Assegnazione per il periodo 2008–2012 elaborato ai sensi dell’articolo 8, comma 2, del D.lgs. 4 aprile 2006, Nr. 216.

Decreto Ministeriale Nr. 96 (2006), sul rilascio del riconoscimento dell’attività di verifica delle comunicazioni delle emissioni prevista dall’articolo Nr.15 della direttiva 2003/87/CE e dall’articolo Nr.4, comma 6, del decreto DEC/RAS/074/2006.

References

Andreola F, Barbieri L, Corradi A, Lancellotti I (2007) CRT glass state of the art—a case study: recycling in ceramic glazes. J Eur Ceram Soc 27(2–3):1623–1629

Baldo GL, Marino M, Rossi S (2005) Analisi del Ciclo di Vita (LCA). Materiali, Prodotti, Processi. Edizioni Ambiente

Bastianoni S, Pulselli FM, Tiezzi E (2004) The problem of assigning responsibility for greenhouse gas emissions. Ecol Econ 49(3):253–257

Bösch ME, Hellweg S, Huijbregts MAJ, Frischknecht R (2007) Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int J Life Cycle Assess 12(3):181–190

Culaba AB, Purvis MRI (1999) A methodology for the life cycle and sustainability analysis of manufacturing processes. J Clean Prod 7:435–445

Decreto legislativo Nr.22 (1997) del 5 febbraio 1997 (Decreto Ronchi). Attuazione delle direttive 91/156/CEE sui rifiuti, 91/689/CEE sui rifiuti pericolosi e 94/62/CE sugli imballaggi e rifiuti di imballaggio

Dreyer L, Niemann AL, Hauschild MZ (2003) Comparison of three different LCIA methods: EDIP97, CML2001 and Eco-indicator 99—does it matter which one you choose? Int J Life Cycle Assess 8(4):191–200

EMEP/CORINAIR (2006) Emission inventory guidebook, 3rd edn (group 3, combustion in manufacturing industry—production of other glass, chapter 8, paragraph 8.4., Table 8.18, 38 pp). Technical report no. 11/2006, European Environment Agency

EU Directive 69/493/EEC (1969). Council Directive of 15 December 1969 on the approximation of the laws of the Member States relating to crystal glass. OJ, 1969. L326, pp 599–602

European Commission (2001) Integrated Pollution Prevention and Control (IPPC), Directorate-General JRG Joint Research Centre (December 2001): reference document on best available techniques in the glass manufacturing industry. Institute for Prospective Technological Studies

European Commission (2006a) Integrated Pollution Prevention and Control (IPPC), Directorate-General JRG Joint Research Centre (December 2006) Reference document on best available techniques for the manufacture of large volume inorganic chemicals—ammonia, acids and fertilizers (chapter 6, paragraph 6.3). Institute for Prospective Technological Studies

European Commission (2006b) Integrated Pollution Prevention and Control (IPPC), Directorate-General JRG Joint Research Centre (December 2006) Reference document on best available techniques in the ceramic manufacturing industry (chapter 3, paragraph 3.3.3). Institute for Prospective Technological Studies

Fthenakis V, Wang W, Kim HC (2009) Life cycle inventory analysis of the production of metals used in photovoltaics. Renew Sustain Energ Rev 13:493–517

Ganapathy S (2000) Barium carbonate from mineral barite. Chem Eng World 1(35):65–72

Guadagnino E, Gambaro M, Gramiccioni L, Denaro M, Feliciani R, Baldini M, Stacchini P, Giovannangeli S, Carelli G, Castellino N, Vinci F (2000) Estimation of lead intake from crystalware under conditions of consumer use. Food Addit Contam 17(3):205–218

Guadagnino E, Verità M, Geotti-Bianchini F, Shallenberger J, Pantano CG (2002) Surface analysis of 24% lead crystal glass articles: correlation with lead release. Glass Technol 43(2):63–69

Guinée JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A, van Oers A, Sleeswijk AW, Suh S, de Haes HAU, de Bruijn H, van Duin R, Huijbregts MAJ (2001) Life cycle assessment, an operational guide to the ISO standard—Part 2b: operational annex, & part 3: scientific background. Centre for Environmental Science, Leiden University, The Netherlands

Heijungs R, Guinée J, Kleijn R, Rovers V (2007) Bias in normalization: causes, consequences, detection and remedies. Int J Life Cycle Assess 12(4):211–216

Higgins CJ, Scott Matthews H, Hendrickson CT, Small MJ (2007) Lead demand of future vehicle technologies. Transp Res Part D Transp Environ 12:103–114

Hynes MJ, Jonson B (1997) Lead, glass and the environment. Chem Soc Rev 26:133–146

ISO 14040 (2006) Environmental management—Life cycle assessment—Principles and framework. The International Organization for Standardization

ISO 14044 (2006) Environmental management—Life cycle assessment—requirements and guidelines. The International Organization for Standardization

Klöpffer W (1996) Allocation rule for open-loop recycling in life cycle assessment—a review. Int J Life Cycle Assess 1(1):27–31

Krulik GA, Sverdlov G, Hannan W (2003) System and method for removal of fluoride from wastewater using single fluoride sensing electrode. United States Patent 6,645,385, 11 November 2003

Lee S, Park H, Lee CH, Lee M, Pak H, Chung K (1997) Clean technology in the crystal glass industry. J Clean Prod 3(5):207–210

Mata TM, Costa AV (2001) Life cycle assessment of different reuse percentages for glass beer bottles. Int J Life Cycle Assess 6(5):307–319

McCulloch A, Lindley AA (2003) From mine to refrigeration: a life cycle inventory analysis of the production of HFC-134a. Int J Refrig 26(8):865–872

META (Modena Energia Territorio Ambiente s.p.a.) (2000) Bilancio ambientale. META, Modena (Italy), pp 73–81

Nordic Council of Ministers (2003) Lead review. Report n.1 (4). January 2003

Pfaender HG (1996) Schott guide to glass, 2nd edn. Springer, Berlin

Ribeiro C, Ferreira JV, Partidàrio P (2007) Life cycle assessment of a multi-material car component. Int J Life Cycle Assess 12(5):336–345

Ridolfi R, Kneller M, Donati A, Pulselli RM (2008) The greenhouse gas balance of the Province of Siena. J Environ Manag 86(2):365–371

Salomone R, Mondello F, Lanuzza F, Micali G (2005) An eco-balance of a recycling plant for spent lead–acid batteries. Environ Manage 35(2):206–219

Shapilova MV, Alimova SI (2000) Environmental problems in the production of household and crystal glass. Glass Ceram 8(57):293–295

Strauss K, Brent A, Hietkamp S (2006) Characterisation and normalisation factors for life cycle impact assessment mined abiotic resources categories in South Africa: the manufacturing of catalytic converter exhaust systems as a case study. Int J Life Cycle Assess 11(3):162–171

van Asselt H, Biermann F (2007) European emissions trading and the international competitiveness of energy-intensive industries: a legal and political evaluation of possible supporting measures. Energy Policy 35(1):497–506

van Santen E, Beerkens R (2005) Recycling in container glass production: present problems in European glass industry. A Collection of Papers Presented at the 66th Conference on Glass Problems, The University of lllinois at Urbana–Champaign, October 24–26

Zhernovaya NF, Onishchuk VI (2003) Regeneration of slime generated in chemical polishing of lead crystal. Glass Ceram 8(60):197–199

Zhernovaya NF, Onishchuk VI (2005) Possible directions in recycling crystal production waste. Glass Ceram 2(62):13–15

Acknowledgements

The authors would like to acknowledge the Colle Vilca s.r.l. crystalware company for technical support in the investigation of important items for the crystal glass LCA. The project has been carried out as a collaboration between the University of Siena and the Consortium of Colle di Val D’Elsa lead crystal producers (Consorzio del Cristallo), supported by this Consortium, the Province of Siena Administration and the “Monte dei Paschi” Foundation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Gian Luca Baldo

Rights and permissions

About this article

Cite this article

Pulselli, R.M., Ridolfi, R., Rugani, B. et al. Application of life cycle assessment to the production of man-made crystal glass. Int J Life Cycle Assess 14, 490–501 (2009). https://doi.org/10.1007/s11367-009-0085-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0085-5