Abstract

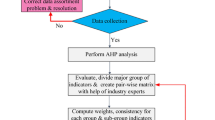

In this paper, a visual, data-driven operational level lean maturity model is developed. The model can be used to assess level of lean maturity and to compare it to performance results in different axes of manufacturing cells in order to evaluate lean effectiveness. As demonstrated in this paper, to measure effectiveness of lean manufacturing, both inputs (tools and processes) and outputs (performance) are measured separately and analyzed together. A case study is carried out for gathering data, analysis, and explanatory study of results. Qualitative and quantitative data on lean capability and performance of two manufacturing cells is collected using historical data and audit. A scoring system based on the major and minor non-conformances is suggested to quantify the indicators of leanness. Minimum of fuzzy membership values is selected to calculate overall performance. Then, the results of leanness are compared with performance to highlight the gaps of lean effectiveness. Results of the study show that the developed model can be used to measure both leanness and lean effectiveness through assessment of lean performance. The model can be applied by practitioners as a framework to design and develop a company-specific lean maturity model.

Similar content being viewed by others

References

Womack JP, Jones DT, and Roos D (1991) The Machine That Changed the World. s.l.:Harper Perennial

Davis D (2013). Trends and Success Factors in Business Process Excellence, s.l.: PEX. Process Excellence Network

LAI-MIT (2001) Lean Enterprise Self Assessment Tool - Facilitator's Guide. s.l.:Massachusetts Institute of Technology

Amin M, and Karim M (2012) A Systematic Approach to Evaluate the Process Improvement in Lean Manufacturing Organizations. In: G. Seliger, ed. Sustainable Manufacturing. s.l.:Springer Berlin Heidelberg, pp. 65-70.

Chauhan G, Singh T (2012) Measuring parameter of lean manufacturing realization. Meas Bus Excell 3(16):57–71

Pakdil F, Moustafa Leonard K (2014) Criteria for a lean organisation: development of a lean assessment tool. Int J Prod Res 52(15):4587–4607

Anvari A, Zulkifli N, Mohd Yusuff R (2012) A dynamic modeling to measure lean performance within lean attributes. Int J Adv Manuf Technol 66(5-8):663–677

Seyedhosseini S, Ebrahimi Taleghani A, Bakhsha A, Partovi S (2011) Extracting leanness criteria by employing the concept of Balanced Scorecard. Expert Systems with Applications: An International Journal 38(8):10454–10461

Tupa J (2013) Performance Measurement for Efficient Lean Management. In: A. Azevedo, ed. Advances in Sustainable and Competitive Manufacturing Systems. s.l.:Springer International Publishing, pp. 1375-1384

Netland T (2013) Exploring the phenomenon of company-specific production systems: one-best-way or own-best-way? Int J Prod Res 51(4):1084–1097

Chiarini A (2013) Lean organization: from the Tools of the Toyota Production System to Lean Office. s.l. Springer, Milan

Shah R, Ward P (2003) Lean manufacturing: context, practice bundles, and performance. J Oper Manag 21(2):129–149(21)

Shingo S, and Dillon AP (1989) A Study of the Toyota Production System: From an Industrial Engineering Viewpoin. s.l.:Productivity Press

Spear S, and Bowen H (1999) Decoding the DNA of Toyota Production System, s.l.: Harward Business Review

Hines P, Holweg M, Rich N (2004) Learning to evolve—a review of contemporary lean thinking. Int J Oper Prod Manag 24(10):994–1011

Becker J, Niehaves B, Pöppelbuß J, and Alexander S (2010) Maturity Models in IS ResearcH. Pretoria., s.n

Nesensohn C, Bryde D, Ochieng E, Fearon D (2014) Maturity and maturity models in lean construction. Australasian Journal of Construction 14(1):45–59

Behrouzi F, Wong KY (2013) An integrated stochastic-fuzzy modeling approach for supply chain leanness evaluation. Int J Adv Manuf Technol 68(5-8):1677–1696

SPR (2004) SPR Management Book. SPR Steering Committee, Paris

Miller R (2012) The Shingo Principles of Operational Excellence - Model and Application Guidelines. s.l.:Jon M. Huntsman School of Business - Utah State University

Wan H-d, Chen FF (2009) Decision support for lean practitioners: a web-based adaptive assessment approach. Comput Ind 60(4):277–283

Singh B, Garg S, Sharma S (2010) Development of index for measuring leanness: study of an Indian auto component industry. Meas Bus Excell 14(2):46–53

Vinodh S, Vimal KEK (2012) Thirty criteria based leanness assessment using fuzzy. Int J Adv Manuf Technol 60(9-12):1185–1195

Vinodh S, Chintha SK (2011) Leanness assessment using multi-grade fuzzy approach. Int J Prod Res 49(2):431–445

Zanjirchi SM, Tooranlo HS, Nejad LZ (2010) Measuring organizational leanness using fuzzy approach. International Conference on Industrial Engineering and Operations Management, Dhaka

Yin Rk (2003) Case Study Research. s.l.:Sage Publications

Lemieux A-A, Pellerin R, Lamouri S (2013) A mixed performance and adoption alignment framework for guiding leanness and agility improvement initiatives in product development. Journal of Enterprise Transformation 3(3):161–186

Bhasin S (2008) Lean and performance measurement. J Manuf Technol Manag 19(5):670–684

Zani S, Milioli MA, and Morlini I (2013) Fuzzy Composite Indicators: An Application for Measuring Customer Satisfaction. Advances in Theoretical and Applied Statistics, pp. 243-253

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Kaufmann A, and Gupta MM (1991) Introduction to Fuzzy Arithmetic: Theory and Application. 3rd ed. s.l.:Van Nostrand Reinhold

Klir G, and Yuan B (1995) Fuzzy sets and fuzzy logic. s.l.:New Jersey: Prentice Hall

Pöppelbuß J, and Röglinger M (2011) What Makes a Useful Maturity Model? A framework of general design principles for maturity models and its demonstration in business process. s.l., ECIS 2011 Proceedings

Nightingale D (2009) Principles of enterprise systems. Massachusetts, MIT ESD, Cambridge

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maasouman, M.A., Demirli, K. Development of a lean maturity model for operational level planning. Int J Adv Manuf Technol 83, 1171–1188 (2016). https://doi.org/10.1007/s00170-015-7513-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7513-4